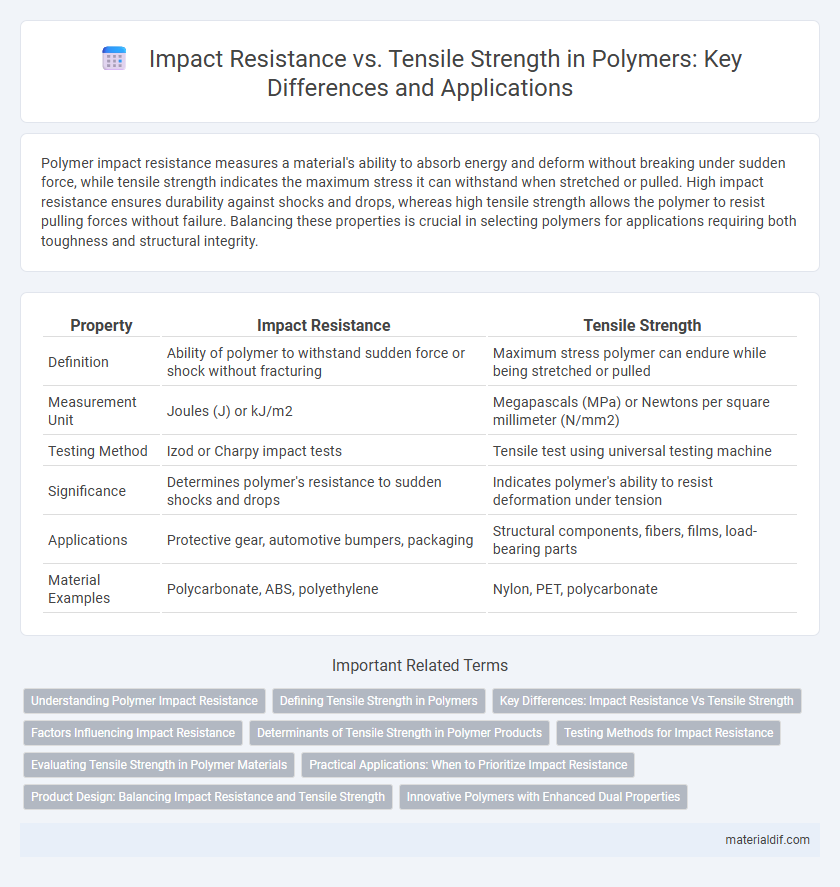

Polymer impact resistance measures a material's ability to absorb energy and deform without breaking under sudden force, while tensile strength indicates the maximum stress it can withstand when stretched or pulled. High impact resistance ensures durability against shocks and drops, whereas high tensile strength allows the polymer to resist pulling forces without failure. Balancing these properties is crucial in selecting polymers for applications requiring both toughness and structural integrity.

Table of Comparison

| Property | Impact Resistance | Tensile Strength |

|---|---|---|

| Definition | Ability of polymer to withstand sudden force or shock without fracturing | Maximum stress polymer can endure while being stretched or pulled |

| Measurement Unit | Joules (J) or kJ/m2 | Megapascals (MPa) or Newtons per square millimeter (N/mm2) |

| Testing Method | Izod or Charpy impact tests | Tensile test using universal testing machine |

| Significance | Determines polymer's resistance to sudden shocks and drops | Indicates polymer's ability to resist deformation under tension |

| Applications | Protective gear, automotive bumpers, packaging | Structural components, fibers, films, load-bearing parts |

| Material Examples | Polycarbonate, ABS, polyethylene | Nylon, PET, polycarbonate |

Understanding Polymer Impact Resistance

Polymer impact resistance measures a material's ability to absorb and dissipate energy during sudden forces, preventing fractures or cracks. This property is crucial for applications requiring durability under dynamic loading, differing from tensile strength which indicates the maximum stress a polymer can withstand while being stretched. Understanding impact resistance helps in selecting polymers for protective gear, automotive parts, and packaging materials where shock absorption is essential.

Defining Tensile Strength in Polymers

Tensile strength in polymers measures the maximum stress a material can withstand while being stretched or pulled before breaking, typically expressed in megapascals (MPa). This mechanical property is critical for applications requiring durability under tension, influencing the polymer's ability to resist deformation and failure. Comparing tensile strength to impact resistance highlights a polymer's capacity to endure gradual loading versus sudden force, essential for selecting materials in engineering and manufacturing.

Key Differences: Impact Resistance Vs Tensile Strength

Impact resistance measures a polymer's ability to absorb energy and withstand sudden forces without fracturing, crucial for applications subject to shocks or drops. Tensile strength quantifies the maximum stress a polymer can endure while being stretched or pulled before breaking, indicating its load-bearing capacity. Understanding the key differences helps in selecting polymers that balance durability and flexibility for specific engineering requirements.

Factors Influencing Impact Resistance

Impact resistance in polymers is heavily influenced by molecular structure, including chain flexibility and cross-link density, which absorb and dissipate energy upon impact. Additives such as plasticizers and fillers also enhance toughness by altering the polymer matrix and reducing brittleness. Environmental conditions, including temperature and strain rate, significantly affect impact resistance by impacting polymer mobility and energy absorption capacity.

Determinants of Tensile Strength in Polymer Products

Tensile strength in polymer products is primarily determined by molecular weight, polymer chain orientation, and degree of crystallinity. Higher molecular weight increases chain entanglements, enhancing load-bearing capacity, while oriented polymer chains improve resistance to elongation under stress. Crystallinity promotes intermolecular forces, resulting in greater tensile strength but often reducing impact resistance due to increased brittleness.

Testing Methods for Impact Resistance

Testing methods for impact resistance in polymers commonly include the Izod and Charpy impact tests, which measure the material's ability to absorb energy during sudden impacts. These standardized tests utilize notched specimens to simulate real-world stress concentrations and provide reliable data on polymer toughness. Understanding impact resistance through these methods is crucial for applications requiring durability under dynamic loading, complementing tensile strength assessments that evaluate behavior under static stress.

Evaluating Tensile Strength in Polymer Materials

Tensile strength in polymer materials measures the maximum stress a polymer can endure while being stretched or pulled before breaking, providing critical insight into its durability and load-bearing capacity. Evaluating tensile strength involves standardized testing methods such as ASTM D638, which assess the polymer's response under uniaxial tension to determine its elasticity, yield point, and breaking point. Understanding tensile strength is essential for selecting polymers for applications requiring resistance to deformation and mechanical stress, as it directly influences impact resistance and overall material performance.

Practical Applications: When to Prioritize Impact Resistance

Impact resistance is prioritized over tensile strength in applications where materials must absorb sudden shocks or high-force impacts without fracturing, such as in automotive bumpers, protective helmets, and safety gear. Polymers like polycarbonate and certain high-impact ABS grades are preferred for their ability to withstand dynamic stresses while maintaining structural integrity. This focus ensures durability and safety in environments subject to unpredictable forces or repetitive impacts.

Product Design: Balancing Impact Resistance and Tensile Strength

In product design, balancing impact resistance and tensile strength in polymers is crucial for optimizing durability and performance under stress. Polymers like polycarbonate offer high impact resistance, while materials such as nylon provide superior tensile strength, making material selection dependent on application-specific load and impact requirements. Advanced composite polymers combine these properties to enhance structural integrity without compromising flexibility or toughness.

Innovative Polymers with Enhanced Dual Properties

Innovative polymers with enhanced dual properties achieve a balanced combination of high impact resistance and superior tensile strength through advanced molecular engineering techniques such as copolymerization and nanocomposite integration. These polymers exhibit improved energy absorption and stress distribution, enabling applications in automotive, aerospace, and protective equipment industries. Enhanced dual-performance materials offer extended durability and reliability under dynamic loading conditions, outperforming conventional single-property polymers.

Impact Resistance vs Tensile Strength Infographic

materialdif.com

materialdif.com