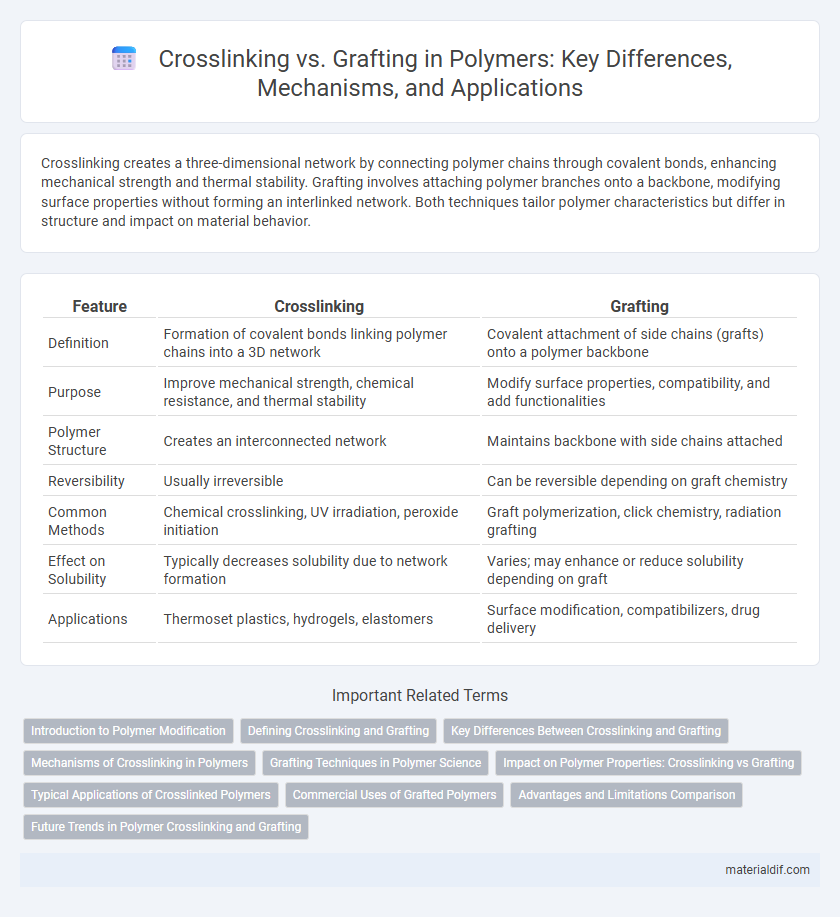

Crosslinking creates a three-dimensional network by connecting polymer chains through covalent bonds, enhancing mechanical strength and thermal stability. Grafting involves attaching polymer branches onto a backbone, modifying surface properties without forming an interlinked network. Both techniques tailor polymer characteristics but differ in structure and impact on material behavior.

Table of Comparison

| Feature | Crosslinking | Grafting |

|---|---|---|

| Definition | Formation of covalent bonds linking polymer chains into a 3D network | Covalent attachment of side chains (grafts) onto a polymer backbone |

| Purpose | Improve mechanical strength, chemical resistance, and thermal stability | Modify surface properties, compatibility, and add functionalities |

| Polymer Structure | Creates an interconnected network | Maintains backbone with side chains attached |

| Reversibility | Usually irreversible | Can be reversible depending on graft chemistry |

| Common Methods | Chemical crosslinking, UV irradiation, peroxide initiation | Graft polymerization, click chemistry, radiation grafting |

| Effect on Solubility | Typically decreases solubility due to network formation | Varies; may enhance or reduce solubility depending on graft |

| Applications | Thermoset plastics, hydrogels, elastomers | Surface modification, compatibilizers, drug delivery |

Introduction to Polymer Modification

Crosslinking forms covalent bonds between polymer chains, enhancing mechanical strength, thermal stability, and chemical resistance by creating a three-dimensional network. Grafting involves attaching side chains or functional groups onto the main polymer backbone, tailoring surface properties, compatibility, and reactivity without significantly altering the bulk polymer structure. These polymer modification techniques enable customized material performance for applications in coatings, adhesives, and biomedical devices.

Defining Crosslinking and Grafting

Crosslinking in polymers refers to the process of chemically joining two or more polymer chains through covalent bonds, enhancing mechanical strength and thermal stability. Grafting involves attaching side chains of one polymer onto the backbone of another polymer, modifying surface properties and compatibility without significantly altering the main chain structure. Both techniques tailor polymer characteristics but differ fundamentally in their structural modification approaches.

Key Differences Between Crosslinking and Grafting

Crosslinking forms covalent or ionic bonds between polymer chains, creating a three-dimensional network that enhances mechanical strength, thermal stability, and chemical resistance. Grafting involves attaching side chains of different polymers onto a main polymer backbone, modifying surface properties and compatibility without significantly altering the polymer's bulk structure. Key differences include crosslinking's role in network formation and rigidity, whereas grafting primarily tailors surface functionality and polymer blend compatibility.

Mechanisms of Crosslinking in Polymers

Crosslinking in polymers occurs through chemical or physical interactions forming covalent or ionic bonds between polymer chains, enhancing mechanical strength and thermal stability. Common mechanisms include free radical polymerization, where reactive species create covalent bonds, and ionic crosslinking involving metal ions bridging polymer chains. Physical crosslinking also happens via hydrogen bonding, crystallite formation, or entanglements, impacting polymer elasticity and solvent resistance.

Grafting Techniques in Polymer Science

Grafting techniques in polymer science involve the covalent attachment of polymer chains onto a backbone polymer, enhancing material properties such as mechanical strength, chemical resistance, and functionality. Methods like graft copolymerization, including "grafting from," "grafting onto," and "grafting through," enable precise control over polymer architecture and surface characteristics. These techniques are essential for developing advanced materials used in biomedical devices, coatings, and nanocomposites.

Impact on Polymer Properties: Crosslinking vs Grafting

Crosslinking creates covalent bonds between polymer chains, enhancing mechanical strength, thermal stability, and chemical resistance by forming a three-dimensional network. Grafting attaches side chains onto a polymer backbone, improving surface properties like adhesion, compatibility, and hydrophilicity without significantly altering bulk mechanical properties. The impact of crosslinking is more pronounced on elasticity and durability, while grafting primarily tailors functionality and interfacial interactions.

Typical Applications of Crosslinked Polymers

Crosslinked polymers are widely used in applications requiring enhanced mechanical strength, thermal stability, and chemical resistance, such as in rubber tires, adhesives, and hydrogels. Their 3D network structure improves durability and elasticity, making them ideal for coatings, sealants, and biomedical devices like drug delivery systems. Compared to grafting, crosslinking provides superior solvent resistance and shape retention crucial for industrial and consumer products.

Commercial Uses of Grafted Polymers

Grafted polymers are widely utilized in commercial applications such as packaging, biomedical devices, and textiles due to their enhanced surface properties and improved compatibility with other materials. The grafting process enables the introduction of functional groups that tailor polymer characteristics, making them ideal for adhesives, coatings, and drug delivery systems. Unlike crosslinking, grafting allows for greater control over polymer architecture, resulting in versatile products with specific performance criteria in diverse industrial sectors.

Advantages and Limitations Comparison

Crosslinking enhances polymer network strength and thermal stability by forming covalent bonds between polymer chains, improving mechanical properties but often reducing solubility and flexibility. Grafting introduces functional groups or chains onto the polymer backbone, offering tailored surface properties and increased compatibility with other materials while maintaining processability. Crosslinking's limitation lies in irreversible structural modification, whereas grafting may result in less uniform property enhancement and potential phase separation.

Future Trends in Polymer Crosslinking and Grafting

Future trends in polymer crosslinking emphasize sustainable and stimulus-responsive methods, integrating green chemistry principles to enhance material recyclability and performance. Advances in grafting techniques focus on precision at the molecular level using controlled radical polymerization and click chemistry to create functionalized polymers with tailored properties. Emerging applications in biomedicine and nanotechnology drive innovation towards hybrid crosslinked-grafted networks for multifunctional, smart polymer systems.

Crosslinking vs Grafting Infographic

materialdif.com

materialdif.com