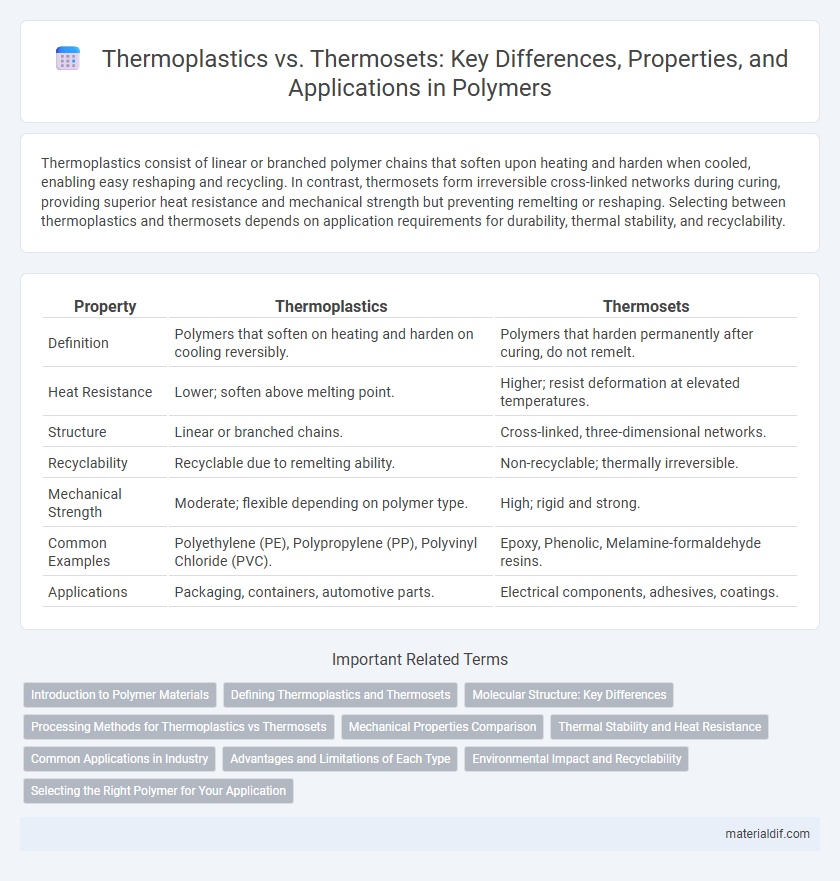

Thermoplastics consist of linear or branched polymer chains that soften upon heating and harden when cooled, enabling easy reshaping and recycling. In contrast, thermosets form irreversible cross-linked networks during curing, providing superior heat resistance and mechanical strength but preventing remelting or reshaping. Selecting between thermoplastics and thermosets depends on application requirements for durability, thermal stability, and recyclability.

Table of Comparison

| Property | Thermoplastics | Thermosets |

|---|---|---|

| Definition | Polymers that soften on heating and harden on cooling reversibly. | Polymers that harden permanently after curing, do not remelt. |

| Heat Resistance | Lower; soften above melting point. | Higher; resist deformation at elevated temperatures. |

| Structure | Linear or branched chains. | Cross-linked, three-dimensional networks. |

| Recyclability | Recyclable due to remelting ability. | Non-recyclable; thermally irreversible. |

| Mechanical Strength | Moderate; flexible depending on polymer type. | High; rigid and strong. |

| Common Examples | Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC). | Epoxy, Phenolic, Melamine-formaldehyde resins. |

| Applications | Packaging, containers, automotive parts. | Electrical components, adhesives, coatings. |

Introduction to Polymer Materials

Thermoplastics are polymer materials that soften when heated and harden upon cooling, allowing for multiple reshaping cycles, making them ideal for applications requiring recyclability and flexibility. Thermosets, in contrast, undergo a chemical curing process that forms irreversible cross-linked networks, providing superior thermal stability, mechanical strength, and resistance to deformation under heat. Understanding the fundamental differences between thermoplastics and thermosets is essential for selecting appropriate polymer materials in manufacturing, electronics, automotive, and aerospace industries.

Defining Thermoplastics and Thermosets

Thermoplastics are polymers that become pliable or moldable above a specific temperature and solidify upon cooling, allowing for repeated reshaping without altering their chemical structure. Thermosets, in contrast, undergo an irreversible curing process that forms a rigid three-dimensional network, making them permanently hard and resistant to melting or reshaping. The key difference lies in the molecular bonding: thermoplastics have linear or branched chains, while thermosets possess cross-linked networks.

Molecular Structure: Key Differences

Thermoplastics consist of linear or branched polymer chains without cross-linking, allowing them to soften and reshape upon heating due to intermolecular forces. Thermosets feature a heavily cross-linked, three-dimensional network of covalent bonds, providing rigidity and thermal stability that prevent melting or reshaping once cured. These fundamental molecular structure differences critically determine their mechanical properties, thermal resistance, and recyclability.

Processing Methods for Thermoplastics vs Thermosets

Thermoplastics are processed through melting and reshaping techniques such as injection molding, extrusion, and blow molding, allowing repeated heating and cooling cycles without significant chemical change. Thermosets require curing through chemical reactions like cross-linking during processes such as compression molding and transfer molding, resulting in a rigid, heat-resistant structure that cannot be remelted. This fundamental difference dictates the choice of processing methods, with thermoplastics favoring melt-based shaping and thermosets relying on chemical hardening.

Mechanical Properties Comparison

Thermoplastics exhibit higher impact resistance and greater elongation at break compared to thermosets, making them more flexible under stress. Thermosets possess superior tensile strength and thermal stability due to their cross-linked molecular structure, enabling them to withstand higher loads without deformation. The mechanical robustness of thermosets is ideal for structural applications, while thermoplastics offer better toughness and recyclability for dynamic environments.

Thermal Stability and Heat Resistance

Thermoplastics soften and become moldable upon heating due to their linear or branched polymer chains, exhibiting moderate thermal stability suited for applications below 250degC. Thermosets possess cross-linked polymer structures that provide superior heat resistance and thermal stability, enabling them to withstand temperatures often exceeding 300degC without deformation. The inherent rigidity of thermosets makes them ideal for high-temperature environments, while thermoplastics offer ease of processing and recyclability under controlled thermal conditions.

Common Applications in Industry

Thermoplastics, such as polyethylene and polypropylene, are widely used in packaging, automotive parts, and consumer goods due to their recyclability and flexibility. Thermosets, including epoxy and phenolic resins, find applications in electrical insulation, adhesives, and structural components because of their excellent heat resistance and mechanical strength. The choice between thermoplastics and thermosets in industry relies on specific performance requirements like durability, thermal stability, and ease of manufacturing.

Advantages and Limitations of Each Type

Thermoplastics offer excellent recyclability and ease of processing due to their ability to be repeatedly melted and reshaped, making them ideal for applications requiring flexibility and cost efficiency. However, they generally exhibit lower thermal resistance and mechanical strength compared to thermosets, limiting their use in high-temperature or high-stress environments. Thermosets provide superior thermal stability, chemical resistance, and mechanical robustness through their permanently cross-linked molecular structure, yet they cannot be remelted or reshaped, leading to challenges in recycling and repair.

Environmental Impact and Recyclability

Thermoplastics offer superior recyclability due to their ability to be repeatedly melted and reshaped, significantly reducing environmental waste compared to thermosets, which undergo irreversible curing processes forming cross-linked structures that hinder recycling efforts. The energy consumption for recycling thermoplastics is generally lower, contributing to a smaller carbon footprint, whereas thermosets often require energy-intensive methods such as grinding and incineration for disposal. Innovations in chemical recycling and biodegradable thermoplastics are enhancing sustainability, yet thermosets remain challenging to repurpose, posing long-term environmental concerns.

Selecting the Right Polymer for Your Application

Thermoplastics, characterized by their ability to be melted and reshaped multiple times, offer excellent flexibility and ease of processing for applications requiring recyclability and repairability. Thermosets, formed through irreversible chemical curing, provide superior mechanical strength, chemical resistance, and thermal stability, making them ideal for high-performance and structural uses. Selecting the right polymer depends on factors such as thermal requirements, mechanical load, environmental exposure, and the need for dimensional stability or recyclability in the specific application.

Thermoplastics vs Thermosets Infographic

materialdif.com

materialdif.com