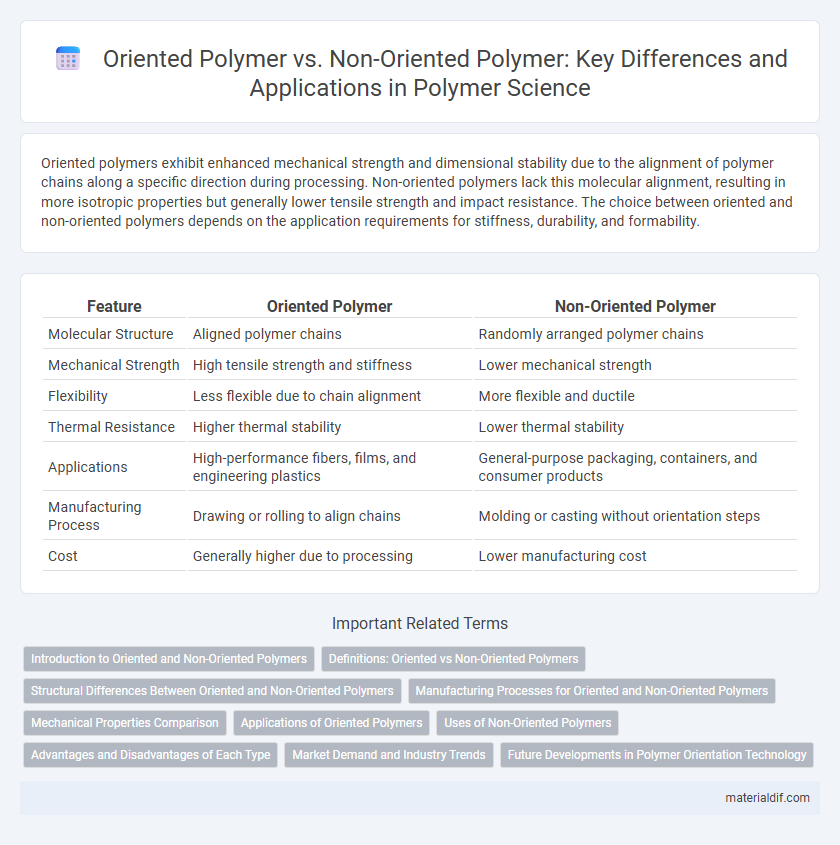

Oriented polymers exhibit enhanced mechanical strength and dimensional stability due to the alignment of polymer chains along a specific direction during processing. Non-oriented polymers lack this molecular alignment, resulting in more isotropic properties but generally lower tensile strength and impact resistance. The choice between oriented and non-oriented polymers depends on the application requirements for stiffness, durability, and formability.

Table of Comparison

| Feature | Oriented Polymer | Non-Oriented Polymer |

|---|---|---|

| Molecular Structure | Aligned polymer chains | Randomly arranged polymer chains |

| Mechanical Strength | High tensile strength and stiffness | Lower mechanical strength |

| Flexibility | Less flexible due to chain alignment | More flexible and ductile |

| Thermal Resistance | Higher thermal stability | Lower thermal stability |

| Applications | High-performance fibers, films, and engineering plastics | General-purpose packaging, containers, and consumer products |

| Manufacturing Process | Drawing or rolling to align chains | Molding or casting without orientation steps |

| Cost | Generally higher due to processing | Lower manufacturing cost |

Introduction to Oriented and Non-Oriented Polymers

Oriented polymers exhibit molecular chains aligned in a specific direction, enhancing mechanical strength, stiffness, and thermal stability, making them ideal for high-performance applications like fibers and films. Non-oriented polymers have randomly arranged molecular chains, resulting in isotropic properties with lower tensile strength but greater flexibility, often used in general-purpose plastics and packaging. Understanding the orientation of polymers is essential for tailoring material properties to meet specific performance requirements in various industries.

Definitions: Oriented vs Non-Oriented Polymers

Oriented polymers are materials in which the polymer chains are aligned in a specific direction, resulting in enhanced mechanical strength, stiffness, and thermal stability. Non-oriented polymers feature randomly arranged chains, leading to isotropic properties with lower tensile strength and reduced resistance to deformation. This molecular alignment difference fundamentally impacts the polymers' performance in applications such as packaging, textiles, and engineering components.

Structural Differences Between Oriented and Non-Oriented Polymers

Oriented polymers exhibit aligned molecular chains that enhance tensile strength, stiffness, and dimensional stability, unlike non-oriented polymers which have randomly arranged chains leading to isotropic properties. The structural alignment in oriented polymers results from processes like drawing or stretching, creating anisotropic mechanical behavior and improved crystallinity. Non-oriented polymers, lacking this molecular orientation, generally offer greater flexibility but lower mechanical strength and resistance.

Manufacturing Processes for Oriented and Non-Oriented Polymers

Oriented polymers are manufactured through processes such as extrusion followed by drawing, which aligns polymer chains to enhance mechanical strength and thermal resistance. Non-oriented polymers typically undergo molding or casting without post-processing stretching, resulting in isotropic properties with lower tensile strength. The choice between manufacturing techniques directly impacts polymer microstructure, affecting performance and application suitability.

Mechanical Properties Comparison

Oriented polymers exhibit significantly enhanced tensile strength and stiffness compared to non-oriented polymers due to molecular alignment along the polymer chains, which facilitates load transfer and resistance to deformation. Non-oriented polymers display more isotropic mechanical properties with lower tensile strength and elongation at break, resulting from their random amorphous structure. The mechanical performance differences make oriented polymers ideal for applications requiring high strength and durability, while non-oriented polymers are preferred for flexibility and impact resistance.

Applications of Oriented Polymers

Oriented polymers exhibit enhanced mechanical strength, thermal stability, and chemical resistance, making them ideal for high-performance applications such as aerospace components, medical devices, and high-strength fibers. Their molecular alignment improves tensile properties and dimensional stability, which is critical in electronics and packaging industries. Non-oriented polymers lack this alignment, resulting in lower durability and limited application in demanding environments.

Uses of Non-Oriented Polymers

Non-oriented polymers are widely used in applications where uniform properties are more critical than directional strength, such as in packaging films, coatings, and adhesives. Their isotropic nature provides consistent mechanical and thermal behavior, making them ideal for products requiring flexibility and ease of processing. Common examples include polyethylene and polypropylene films for food packaging and protective barriers.

Advantages and Disadvantages of Each Type

Oriented polymers exhibit higher tensile strength, enhanced dimensional stability, and improved barrier properties due to the alignment of polymer chains, making them ideal for applications requiring durability and resistance to deformation. Non-oriented polymers offer greater flexibility, ease of processing, and lower production costs but typically suffer from reduced mechanical strength and poor thermal resistance compared to oriented polymers. Each type suits different industrial uses, with oriented polymers preferred in high-performance packaging and engineering plastics, while non-oriented polymers are favored for cost-effective, flexible films and everyday products.

Market Demand and Industry Trends

Oriented polymers, characterized by enhanced mechanical strength and thermal stability, are experiencing rising market demand driven by applications in high-performance automotive and aerospace sectors. Non-oriented polymers maintain steady consumption due to their versatility and cost-effectiveness in packaging and consumer goods industries. Industry trends highlight a growing shift towards oriented polymers as manufacturers seek materials with superior durability and environmental resistance for advanced engineering uses.

Future Developments in Polymer Orientation Technology

Future developments in polymer orientation technology emphasize enhancing mechanical strength, thermal stability, and barrier properties through advanced techniques such as biaxial stretching and molecular alignment control. Innovations in nanocomposite integration and real-time orientation monitoring systems are expected to optimize polymer performance in high-demand sectors like aerospace, medical devices, and flexible electronics. Research also targets eco-friendly orientation methods that reduce energy consumption and improve recyclability of oriented polymers compared to non-oriented counterparts.

Oriented Polymer vs Non-Oriented Polymer Infographic

materialdif.com

materialdif.com