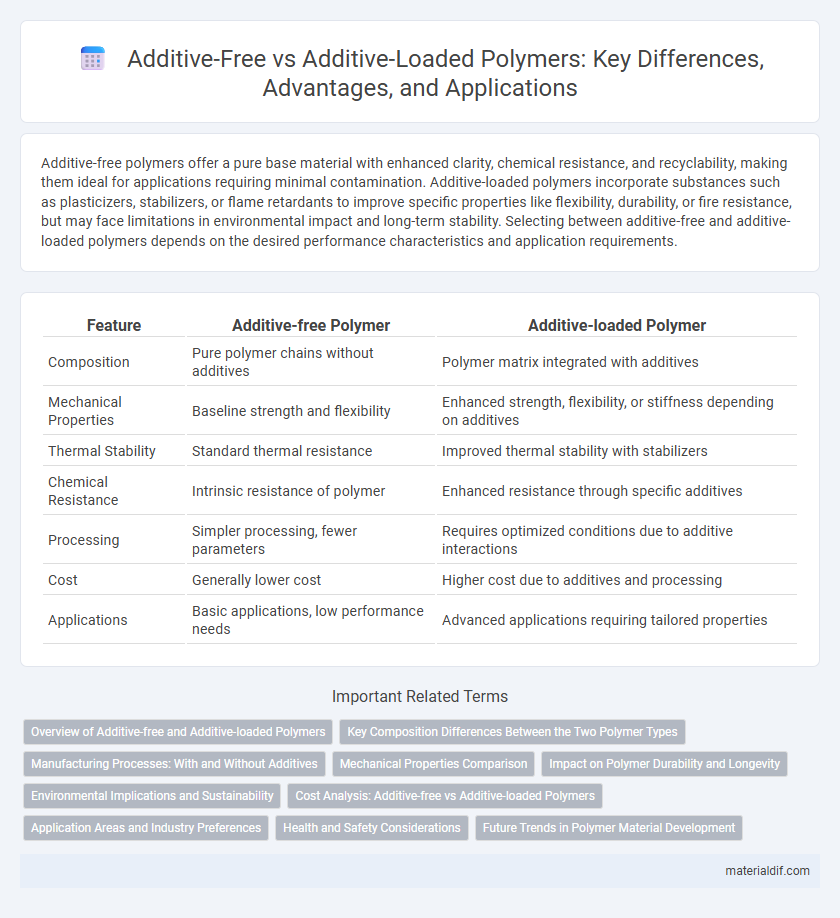

Additive-free polymers offer a pure base material with enhanced clarity, chemical resistance, and recyclability, making them ideal for applications requiring minimal contamination. Additive-loaded polymers incorporate substances such as plasticizers, stabilizers, or flame retardants to improve specific properties like flexibility, durability, or fire resistance, but may face limitations in environmental impact and long-term stability. Selecting between additive-free and additive-loaded polymers depends on the desired performance characteristics and application requirements.

Table of Comparison

| Feature | Additive-free Polymer | Additive-loaded Polymer |

|---|---|---|

| Composition | Pure polymer chains without additives | Polymer matrix integrated with additives |

| Mechanical Properties | Baseline strength and flexibility | Enhanced strength, flexibility, or stiffness depending on additives |

| Thermal Stability | Standard thermal resistance | Improved thermal stability with stabilizers |

| Chemical Resistance | Intrinsic resistance of polymer | Enhanced resistance through specific additives |

| Processing | Simpler processing, fewer parameters | Requires optimized conditions due to additive interactions |

| Cost | Generally lower cost | Higher cost due to additives and processing |

| Applications | Basic applications, low performance needs | Advanced applications requiring tailored properties |

Overview of Additive-free and Additive-loaded Polymers

Additive-free polymers consist solely of base polymer chains without the incorporation of stabilizers, plasticizers, or fillers, resulting in materials with high purity but often limited mechanical and thermal properties. Additive-loaded polymers integrate various additives such as antioxidants, flame retardants, and colorants to enhance performance, durability, and processing characteristics. The choice between additive-free and additive-loaded polymers depends on application-specific requirements including chemical resistance, flexibility, and regulatory compliance.

Key Composition Differences Between the Two Polymer Types

Additive-free polymers consist solely of the base polymer resin without any supplementary substances, resulting in pure material properties that are often less flexible or less resistant to environmental stress. Additive-loaded polymers incorporate various additives such as plasticizers, stabilizers, fillers, and flame retardants, which enhance characteristics like flexibility, durability, UV resistance, and thermal stability. The key compositional difference lies in the presence of these additives that modify the polymer matrix to improve performance tailored for specific applications.

Manufacturing Processes: With and Without Additives

Additive-free polymer manufacturing involves polymerization processes such as bulk or solution polymerization, minimizing contamination and preserving polymer purity, which is critical for high-performance applications. Additive-loaded polymer manufacturing incorporates stabilizers, plasticizers, and fillers during extrusion or compounding stages to enhance mechanical properties, UV resistance, or processing ease but requires precise control to maintain uniform dispersion. The presence or absence of additives directly impacts processing parameters like temperature, mixing speed, and residence time, influencing polymer morphology and final product quality.

Mechanical Properties Comparison

Additive-free polymers typically exhibit baseline mechanical properties such as tensile strength and elongation at break, reflecting their inherent polymer matrix characteristics without enhancements. Additive-loaded polymers show improved mechanical properties, including increased impact resistance, stiffness, and durability, due to the incorporation of fillers, plasticizers, or reinforcing agents. The choice between additive-free and additive-loaded polymers depends on the specific application requirements, where additives provide tailored performance benefits at the expense of potential changes in processability and cost.

Impact on Polymer Durability and Longevity

Additive-free polymers exhibit inherent chemical purity, reducing potential degradation pathways and thus enhancing baseline durability under controlled environments. In contrast, additive-loaded polymers incorporate stabilizers, antioxidants, or UV absorbers that significantly improve resistance to thermal, oxidative, and photodegradation, extending polymer longevity in demanding applications. Optimization of additive type and concentration is critical to achieving a balance between mechanical properties retention and prolonged service life.

Environmental Implications and Sustainability

Additive-free polymers eliminate the environmental risks associated with chemical additives, such as plasticizers, flame retardants, and stabilizers, which can leach into ecosystems and disrupt wildlife. Conversely, additive-loaded polymers often improve material performance but pose challenges in recycling and degradation, contributing to persistent microplastic pollution. Sustainable polymer development prioritizes additive-free formulations or bio-based, biodegradable additives to minimize ecological impact and enhance circularity in plastic waste management.

Cost Analysis: Additive-free vs Additive-loaded Polymers

Additive-free polymers generally exhibit lower initial costs due to the elimination of expenses related to additives, such as stabilizers, plasticizers, and fillers. However, additive-loaded polymers can offer enhanced performance characteristics, potentially reducing lifecycle costs by improving durability, thermal stability, and mechanical properties. The cost analysis must weigh upfront savings against long-term benefits, factoring in application-specific requirements and environmental impact considerations.

Application Areas and Industry Preferences

Additive-free polymers are preferred in medical and food packaging industries due to their purity and reduced risk of contamination, ensuring compliance with stringent safety regulations. Additive-loaded polymers find extensive use in automotive, construction, and electronics sectors where enhanced mechanical properties, UV resistance, and flame retardancy are critical for performance and durability. Industry preferences pivot on balancing the need for material performance with regulatory requirements and application-specific functional demands.

Health and Safety Considerations

Additive-free polymers eliminate the risks associated with chemical additives, reducing potential toxicity, allergenic reactions, and environmental hazards during manufacturing and disposal. Additive-loaded polymers may contain plasticizers, stabilizers, or flame retardants that can leach harmful substances, posing health concerns for consumers and workers. Strict regulatory compliance and material testing are essential to ensure the safety of additive-loaded polymers in medical, food packaging, and consumer applications.

Future Trends in Polymer Material Development

Additive-free polymers are gaining traction in sustainable material development due to their reduced environmental impact and improved recyclability, aligning with increasing regulatory pressures for eco-friendly products. Future trends emphasize advanced molecular design and processing techniques to enhance inherent polymer properties without relying on additives, thus minimizing potential toxicity and environmental hazards. Simultaneously, innovations in additive-loaded polymers focus on bio-based and multifunctional additives to enhance performance while maintaining sustainability goals.

Additive-free Polymer vs Additive-loaded Polymer Infographic

materialdif.com

materialdif.com