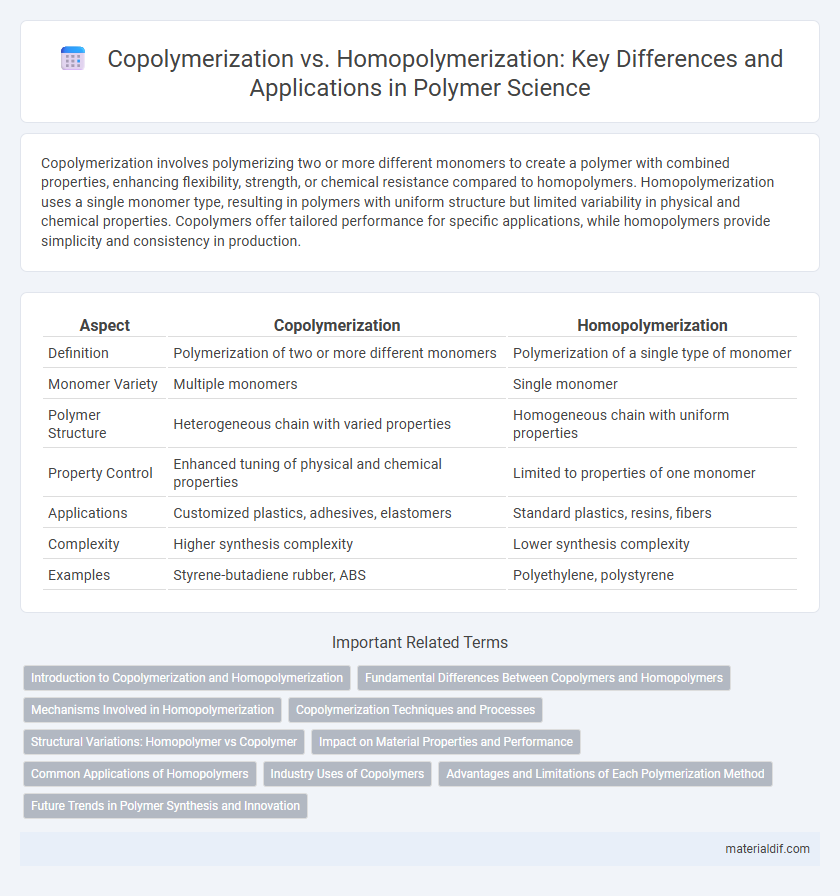

Copolymerization involves polymerizing two or more different monomers to create a polymer with combined properties, enhancing flexibility, strength, or chemical resistance compared to homopolymers. Homopolymerization uses a single monomer type, resulting in polymers with uniform structure but limited variability in physical and chemical properties. Copolymers offer tailored performance for specific applications, while homopolymers provide simplicity and consistency in production.

Table of Comparison

| Aspect | Copolymerization | Homopolymerization |

|---|---|---|

| Definition | Polymerization of two or more different monomers | Polymerization of a single type of monomer |

| Monomer Variety | Multiple monomers | Single monomer |

| Polymer Structure | Heterogeneous chain with varied properties | Homogeneous chain with uniform properties |

| Property Control | Enhanced tuning of physical and chemical properties | Limited to properties of one monomer |

| Applications | Customized plastics, adhesives, elastomers | Standard plastics, resins, fibers |

| Complexity | Higher synthesis complexity | Lower synthesis complexity |

| Examples | Styrene-butadiene rubber, ABS | Polyethylene, polystyrene |

Introduction to Copolymerization and Homopolymerization

Copolymerization involves the polymerization of two or more different monomers to create copolymers with tailored properties, contrasting with homopolymerization which uses a single monomer to form uniform polymer chains. This process enables the design of materials with enhanced mechanical strength, chemical resistance, and thermal stability by combining distinct monomer units. Understanding the differences between copolymerization and homopolymerization is crucial for selecting appropriate polymerization methods for specific applications in industries such as plastics, textiles, and biomedical devices.

Fundamental Differences Between Copolymers and Homopolymers

Copolymerization involves the polymerization of two or more different monomers, resulting in copolymers that exhibit properties distinct from homopolymers formed by a single type of monomer. Copolymers can be tailored to achieve specific mechanical, thermal, and chemical properties by varying the monomer composition and sequence distribution, while homopolymers have uniform repeat units and more predictable characteristics. The structural diversity of copolymers allows for enhanced functionality and versatility in applications compared to the relatively simpler homopolymers.

Mechanisms Involved in Homopolymerization

Homopolymerization involves the polymerization of a single monomer type through mechanisms such as free radical, cationic, anionic, or coordination polymerization, depending on the monomer's reactivity and functional groups. Each mechanism initiates chain growth via distinct active centers, like free radicals in free radical polymerization or carbocations in cationic polymerization, leading to polymer chains composed of repeating identical units. Control over these mechanisms enables precise tailoring of polymer properties such as molecular weight, crystallinity, and thermal stability in homopolymers.

Copolymerization Techniques and Processes

Copolymerization involves the polymerization of two or more different monomers, enabling the synthesis of polymers with tailored properties by incorporating varied functional groups, unlike homopolymerization which uses a single monomer type. Key copolymerization techniques include free radical copolymerization, ionic copolymerization, and coordination copolymerization, each influencing the polymer architecture and composition through distinct reaction mechanisms. Controlled or living copolymerization methods such as reversible addition-fragmentation chain transfer (RAFT) and atom transfer radical polymerization (ATRP) provide precise control over molecular weight distribution and copolymer sequence, enhancing material performance for specialized applications.

Structural Variations: Homopolymer vs Copolymer

Homopolymerization produces polymers consisting of repeating units from a single type of monomer, resulting in uniform chain structures with consistent physical properties. Copolymerization involves the polymerization of two or more different monomers, creating copolymers with varied structural arrangements such as random, alternating, block, or graft configurations. These structural variations influence mechanical strength, thermal stability, and chemical resistance, allowing tailored material properties for specific applications.

Impact on Material Properties and Performance

Copolymerization significantly enhances material properties by incorporating two or more monomers, resulting in improved flexibility, toughness, and chemical resistance compared to homopolymerization, which produces polymers from a single monomer type with more uniform but often limited properties. The ability to tailor copolymer composition allows precise control over thermal stability, mechanical strength, and impact resistance, critical for advanced applications such as automotive parts and medical devices. Homopolymers typically exhibit higher crystallinity and rigidity, while copolymers balance performance attributes, making them versatile for specialized uses.

Common Applications of Homopolymers

Homopolymerization produces polymers consisting of a single type of monomer, resulting in materials with uniform properties ideal for applications such as polyethylene in packaging, polypropylene in automotive parts, and polyvinyl chloride (PVC) in construction. These homopolymers exhibit excellent mechanical strength, chemical resistance, and thermal stability, making them indispensable in industries requiring consistent performance. Their widespread use in packaging films, rigid containers, and pipe systems highlights the critical role of homopolymerization in manufacturing durable and cost-effective polymer products.

Industry Uses of Copolymers

Copolymerization produces materials with tailored properties by combining different monomers, making copolymers highly versatile in industrial applications such as automotive parts, packaging, and adhesives. The ability to enhance mechanical strength, chemical resistance, and thermal stability allows copolymers to outperform homopolymers in specialized uses like impact-resistant plastics and barrier films. This customization drives widespread adoption of copolymerization processes in manufacturing sectors demanding optimized polymer performance.

Advantages and Limitations of Each Polymerization Method

Copolymerization offers enhanced material properties by incorporating two or more different monomers, allowing for tailored mechanical strength, chemical resistance, and thermal stability, which homopolymerization lacks due to its use of a single monomer type. Homopolymerization provides simplicity and cost-effectiveness with consistent polymer structure, but suffers limitations in versatility and performance under varying environmental conditions. Copolymerization challenges include controlling monomer sequence and composition, which can complicate synthesis and increase production costs, while homopolymerization benefits from straightforward reaction mechanisms and uniform polymer chains.

Future Trends in Polymer Synthesis and Innovation

Copolymerization enables the design of polymers with tailored properties by integrating different monomer units, driving innovations in responsive materials and sustainable plastics. Advances in controlled copolymerization techniques, such as reversible-deactivation radical polymerization, enhance precision in molecular architecture, expanding applications in biomedicine and smart coatings. Emerging trends emphasize eco-friendly monomers and energy-efficient processes, positioning copolymerization at the forefront of next-generation polymer synthesis.

Copolymerization vs Homopolymerization Infographic

materialdif.com

materialdif.com