Glass-filled polymers offer enhanced strength and rigidity by incorporating glass fibers, making them ideal for applications requiring impact resistance and durability at a lower cost. Carbon-fiber-reinforced polymers provide superior stiffness, higher tensile strength, and better fatigue resistance, suitable for high-performance and lightweight applications despite their higher price. Both materials improve polymer mechanical properties but differ in weight, cost, and specific performance benefits depending on application requirements.

Table of Comparison

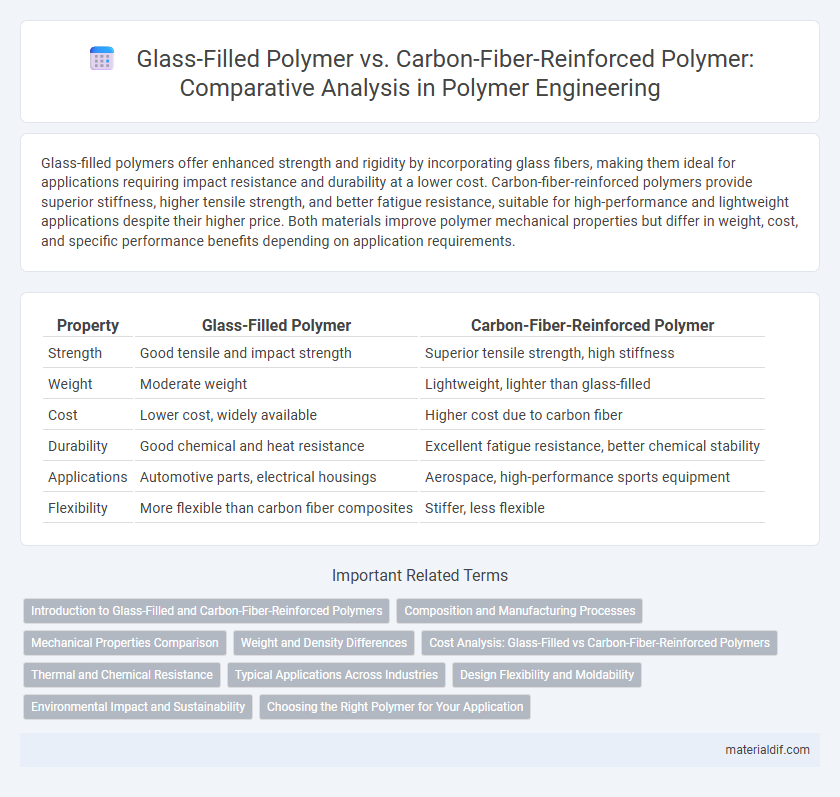

| Property | Glass-Filled Polymer | Carbon-Fiber-Reinforced Polymer |

|---|---|---|

| Strength | Good tensile and impact strength | Superior tensile strength, high stiffness |

| Weight | Moderate weight | Lightweight, lighter than glass-filled |

| Cost | Lower cost, widely available | Higher cost due to carbon fiber |

| Durability | Good chemical and heat resistance | Excellent fatigue resistance, better chemical stability |

| Applications | Automotive parts, electrical housings | Aerospace, high-performance sports equipment |

| Flexibility | More flexible than carbon fiber composites | Stiffer, less flexible |

Introduction to Glass-Filled and Carbon-Fiber-Reinforced Polymers

Glass-filled polymers consist of a polymer matrix reinforced with fine glass fibers, enhancing tensile strength, stiffness, and thermal stability while maintaining cost-effectiveness. Carbon-fiber-reinforced polymers incorporate carbon fibers, offering superior strength-to-weight ratio, high stiffness, and excellent fatigue resistance, making them ideal for aerospace and automotive applications. Both materials improve the mechanical properties of base polymers but differ significantly in performance characteristics and cost implications.

Composition and Manufacturing Processes

Glass-filled polymers consist of a thermoplastic or thermoset matrix reinforced with glass fibers, typically ranging from 10% to 40% by weight, improving strength and rigidity through processes like injection molding or compression molding. Carbon-fiber-reinforced polymers (CFRP) integrate carbon fibers, often 50% to 70% by weight, into a resin matrix, providing superior strength-to-weight ratios and stiffness, commonly fabricated via techniques such as lay-up, resin transfer molding (RTM), or autoclave curing. The manufacturing of CFRPs requires more precise temperature and pressure control to ensure fiber alignment and optimal matrix curing, resulting in higher performance composites compared to the more cost-effective, corrosion-resistant glass-filled polymers.

Mechanical Properties Comparison

Glass-filled polymers exhibit high tensile strength and improved stiffness compared to unreinforced polymers, with tensile strengths typically ranging from 50 to 150 MPa and modulus of elasticity between 10 to 25 GPa. Carbon-fiber-reinforced polymers demonstrate superior mechanical properties, featuring tensile strengths often exceeding 500 MPa and elastic moduli above 70 GPa, resulting in higher strength-to-weight ratios. The enhanced rigidity and fatigue resistance of carbon-fiber composites make them preferable in high-performance applications, whereas glass-filled polymers offer cost-effective solutions with moderate mechanical enhancements.

Weight and Density Differences

Glass-filled polymers typically exhibit higher density and weight compared to carbon-fiber-reinforced polymers due to the greater density of glass fibers, which ranges around 2.5 g/cm3 versus carbon fibers at approximately 1.75 g/cm3. The lower density of carbon fibers results in carbon-fiber-reinforced polymers providing superior strength-to-weight ratios, making them ideal for aerospace and automotive applications where weight reduction is crucial. These weight and density differences significantly influence the material selection process in engineering designs prioritizing performance and fuel efficiency.

Cost Analysis: Glass-Filled vs Carbon-Fiber-Reinforced Polymers

Glass-filled polymers generally offer a more cost-effective solution compared to carbon-fiber-reinforced polymers, with raw material prices often being 50-70% lower. Manufacturing processes for glass-filled polymers tend to require less specialized equipment and shorter cycle times, contributing to reduced overall production costs. While carbon-fiber-reinforced polymers provide superior strength-to-weight ratios, their higher material and processing expenses typically limit their use to high-performance applications where cost is less restrictive.

Thermal and Chemical Resistance

Glass-filled polymer exhibits strong thermal stability with a typical heat deflection temperature ranging from 120degC to 160degC, making it suitable for applications requiring moderate heat resistance. Carbon-fiber-reinforced polymer offers superior thermal resistance, often exceeding 200degC, due to its high melting point and excellent heat dissipation properties. Chemically, carbon-fiber-reinforced polymers demonstrate enhanced resistance to corrosive substances and solvents compared to glass-filled polymers, which can degrade under prolonged chemical exposure.

Typical Applications Across Industries

Glass-filled polymers are widely utilized in automotive components, electrical housings, and consumer goods due to their high durability and cost-effectiveness. Carbon-fiber-reinforced polymers dominate aerospace, sports equipment, and high-performance automotive sectors, offering superior strength-to-weight ratios and stiffness. Industries prioritize these composites based on performance requirements, with glass-filled options favored for mass production and carbon-fiber composites chosen for advanced engineering applications.

Design Flexibility and Moldability

Glass-filled polymer offers enhanced design flexibility and moldability due to its compatibility with complex geometries and detailed features, enabling cost-effective mass production. In comparison, carbon-fiber-reinforced polymer provides superior strength-to-weight ratio but presents challenges in molding intricate shapes, often requiring specialized processes like autoclaving or vacuum bagging. Designers favor glass-filled polymers for applications demanding intricate detail and high-volume manufacturing, while carbon-fiber composites are preferred where structural performance outweighs ease of fabrication.

Environmental Impact and Sustainability

Glass-filled polymers typically have higher environmental footprints due to energy-intensive glass fiber production and limited recyclability, whereas carbon-fiber-reinforced polymers offer greater strength-to-weight ratios but suffer from even more challenging recycling processes and higher carbon emissions during manufacturing. Both materials rely on non-renewable resources, yet advancements in recycling technologies for carbon fibers and bio-based resin matrices are driving improved sustainability profiles. Choosing between these polymers requires balancing performance needs with environmental impact, emphasizing the growing importance of circular economy practices in composite material design.

Choosing the Right Polymer for Your Application

Glass-filled polymers offer enhanced strength and rigidity at a lower cost, making them ideal for applications requiring moderate weight reduction and durability. Carbon-fiber-reinforced polymers provide superior stiffness, high strength-to-weight ratio, and excellent fatigue resistance, suitable for aerospace, automotive, and high-performance sporting goods. Selecting the right polymer depends on specific application requirements like mechanical performance, budget constraints, and environmental exposure.

Glass-Filled Polymer vs Carbon-Fiber-Reinforced Polymer Infographic

materialdif.com

materialdif.com