Laminates consist of multiple layers of polymer materials bonded together to enhance strength and durability, primarily used for surface protection and aesthetic appeal. Composites combine polymers with reinforcing fibers such as fiberglass or carbon fibers, resulting in superior mechanical properties like higher strength-to-weight ratios and improved structural performance. Choosing between laminates and composites depends on the specific application requirements, including load-bearing capacity, flexibility, and resistance to environmental factors.

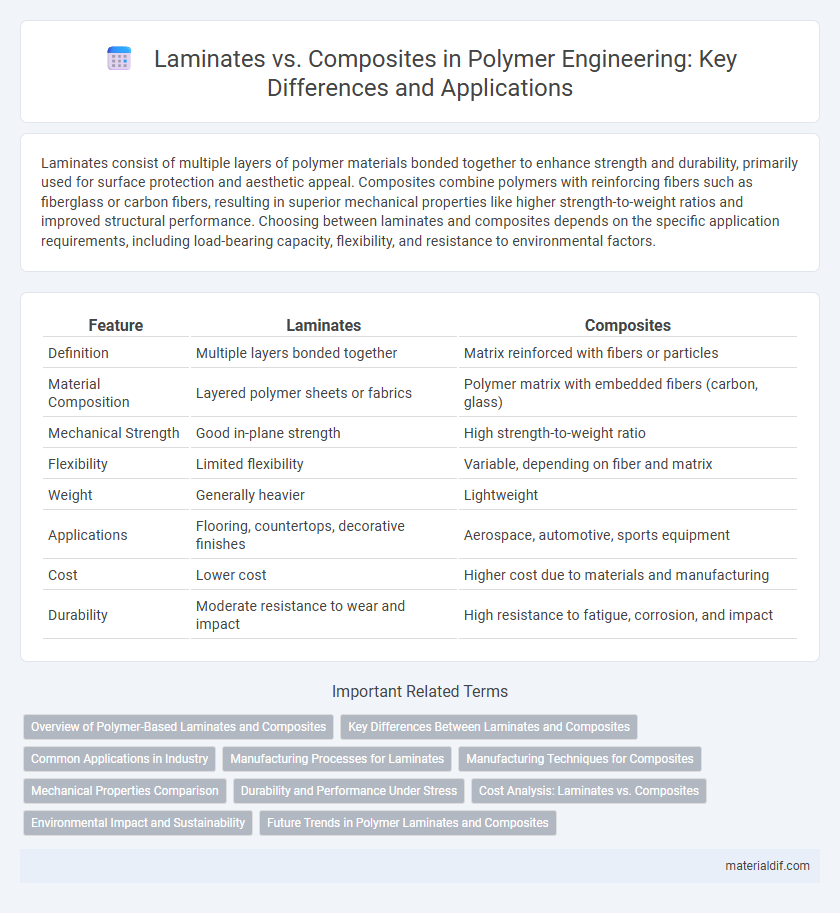

Table of Comparison

| Feature | Laminates | Composites |

|---|---|---|

| Definition | Multiple layers bonded together | Matrix reinforced with fibers or particles |

| Material Composition | Layered polymer sheets or fabrics | Polymer matrix with embedded fibers (carbon, glass) |

| Mechanical Strength | Good in-plane strength | High strength-to-weight ratio |

| Flexibility | Limited flexibility | Variable, depending on fiber and matrix |

| Weight | Generally heavier | Lightweight |

| Applications | Flooring, countertops, decorative finishes | Aerospace, automotive, sports equipment |

| Cost | Lower cost | Higher cost due to materials and manufacturing |

| Durability | Moderate resistance to wear and impact | High resistance to fatigue, corrosion, and impact |

Overview of Polymer-Based Laminates and Composites

Polymer-based laminates consist of multiple layers of polymer films bonded together, enhancing mechanical strength, chemical resistance, and thermal stability for applications in packaging and electronics. Composites combine polymer matrices with reinforcing materials such as fibers or fillers, producing lightweight structures with superior strength-to-weight ratios used in aerospace, automotive, and construction industries. The key distinction lies in the layered architecture of laminates versus the homogeneously distributed reinforcement within composites, influencing performance characteristics and application suitability.

Key Differences Between Laminates and Composites

Laminates consist of multiple bonded layers of similar or dissimilar materials, primarily designed to improve mechanical strength and thermal resistance through stacking and adhesive bonding. Composites combine two or more distinct materials, such as fibers and resin matrices, to achieve enhanced properties like high strength-to-weight ratio and superior durability. The key difference lies in laminates focusing on layer-based reinforcement, while composites leverage a matrix and reinforcement phase for multifunctional performance.

Common Applications in Industry

Laminates are widely used in the packaging industry for flexible films and protective layers due to their excellent barrier properties and lightweight nature. Composites dominate aerospace and automotive sectors where high strength-to-weight ratios and structural integrity are crucial, utilizing materials like carbon fiber-reinforced polymers. Both materials find significant roles in construction, with laminates providing decorative surfaces and composites offering durable panels and reinforcements.

Manufacturing Processes for Laminates

Manufacturing processes for laminates primarily involve layering sheets of polymer resin-impregnated fibers or fabrics, followed by curing under heat and pressure to form a solid, cohesive structure. Techniques like hand lay-up, vacuum bagging, and autoclave curing ensure precise resin distribution and fiber alignment, enhancing mechanical properties and surface finish. This controlled layering process distinguishes laminates from composites, which often incorporate more complex matrices and fiber orientations for tailored performance.

Manufacturing Techniques for Composites

Composites manufacturing techniques predominantly include processes such as resin transfer molding (RTM), filament winding, and autoclave curing, enabling precise control over fiber orientation and resin infusion. Advanced methods like vacuum-assisted resin transfer molding (VARTM) and automated fiber placement (AFP) enhance structural integrity and reduce production time for high-performance composite materials. These techniques differ significantly from laminate fabrication, which typically involves simpler layering and bonding of pre-formed sheets without extensive resin flow management.

Mechanical Properties Comparison

Laminates exhibit high stiffness and excellent dimensional stability due to their layered structure, making them ideal for applications requiring resistance to bending and tensile stress. Composites offer superior strength-to-weight ratios and enhanced impact resistance by combining reinforcing fibers with polymer matrices, resulting in greater toughness and fatigue resistance. Mechanical properties such as tensile strength, flexural modulus, and impact energy absorption are typically higher in composites compared to laminates, driven by fiber orientation and matrix bonding.

Durability and Performance Under Stress

Laminates consist of multiple bonded layers that provide enhanced impact resistance and dimensional stability, making them highly durable in static load applications. Composites combine fibers such as carbon or glass with resin matrices, offering superior strength-to-weight ratios and exceptional performance under dynamic and cyclic stress conditions. The anisotropic nature of composites allows tailored mechanical properties, outperforming laminates in fatigue resistance and long-term structural integrity.

Cost Analysis: Laminates vs. Composites

Laminates generally offer lower initial costs compared to composites due to simpler manufacturing processes and the use of less expensive raw materials such as paper or fabric layers bonded with resins. Composites, while typically more expensive upfront because of advanced materials like carbon fiber or glass fiber reinforced polymers and complex fabrication techniques, deliver superior strength-to-weight ratios and longer service life, often resulting in lower life-cycle costs. Cost analysis should account for both upfront investment and long-term savings, with laminates suitable for budget-sensitive applications and composites favored in high-performance, durability-critical uses.

Environmental Impact and Sustainability

Laminates and composites differ significantly in environmental impact and sustainability, with laminates often relying on thermoset resins that hinder recyclability and increase landfill waste. Composites engineered with bio-based resins and recyclable fibers offer enhanced sustainability by reducing carbon footprint and enabling material recovery. Advances in composite recycling technologies and the use of renewable raw materials position composites as a more eco-friendly solution compared to traditional laminated materials.

Future Trends in Polymer Laminates and Composites

Advancements in polymer laminates and composites emphasize the integration of nanomaterials and bio-based resins, driving superior mechanical strength and sustainability. Smart laminates with embedded sensors enable real-time structural health monitoring, enhancing safety and lifespan in aerospace and automotive applications. Future trends prioritize lightweight, high-performance composites with recyclability to meet stringent environmental regulations and evolving industry demands.

Laminates vs Composites Infographic

materialdif.com

materialdif.com