Linear polymers consist of long, continuous chains of repeating units that provide high density and crystallinity, resulting in greater tensile strength and melting points compared to branched polymers. Branched polymers have side chains attached to the main chain, which reduces chain packing efficiency, lowers density, and enhances flexibility and impact resistance. The structural differences between linear and branched polymers significantly influence their physical properties and applications, especially in manufacturing and material science.

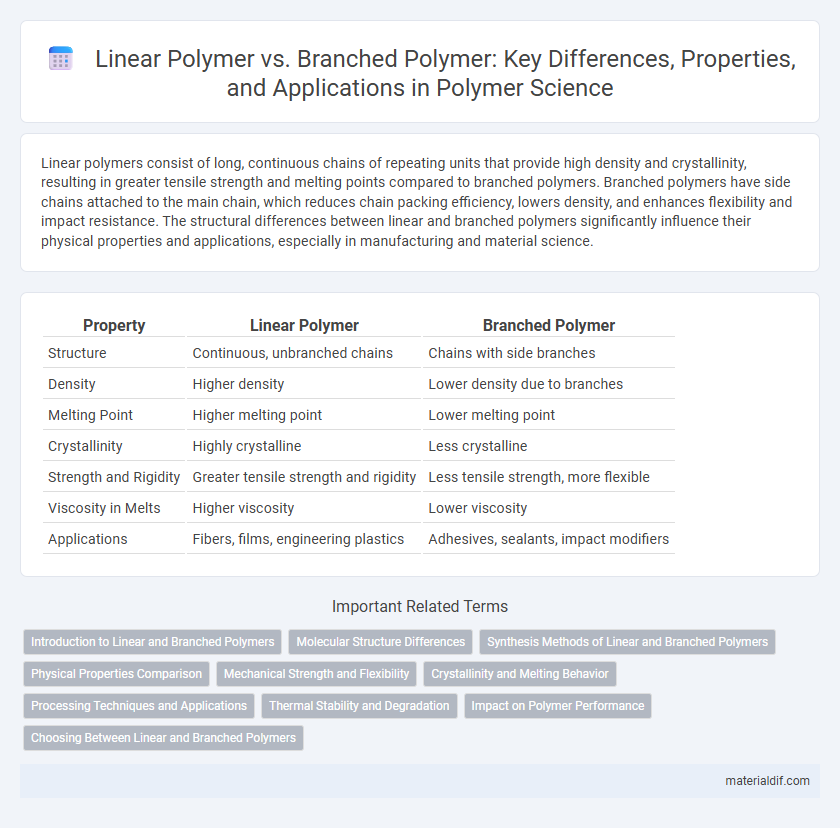

Table of Comparison

| Property | Linear Polymer | Branched Polymer |

|---|---|---|

| Structure | Continuous, unbranched chains | Chains with side branches |

| Density | Higher density | Lower density due to branches |

| Melting Point | Higher melting point | Lower melting point |

| Crystallinity | Highly crystalline | Less crystalline |

| Strength and Rigidity | Greater tensile strength and rigidity | Less tensile strength, more flexible |

| Viscosity in Melts | Higher viscosity | Lower viscosity |

| Applications | Fibers, films, engineering plastics | Adhesives, sealants, impact modifiers |

Introduction to Linear and Branched Polymers

Linear polymers consist of long, continuous chains of repeating monomer units connected end-to-end, resulting in a simple, unbranched structure that often leads to high density and crystallinity. Branched polymers have side chains attached to the main polymer backbone, which reduces packing efficiency and typically lowers density while enhancing impact resistance and flexibility. The structural differences between linear and branched polymers significantly influence their mechanical properties, thermal behavior, and processing techniques.

Molecular Structure Differences

Linear polymers consist of long, continuous chains with repeating units connected end-to-end, resulting in a simpler, more ordered molecular structure. Branched polymers feature side chains or branches attached to the main chain, creating a more complex and irregular three-dimensional architecture. The molecular structure differences influence properties such as density, melting point, and solubility, with linear polymers typically exhibiting higher crystallinity and packing efficiency compared to branched polymers.

Synthesis Methods of Linear and Branched Polymers

Linear polymers are typically synthesized through step-growth or chain-growth polymerization techniques, such as free radical, anionic, or cationic polymerization, promoting the formation of long, unbranched polymer chains. Branched polymers are often produced via controlled branching during polymerization, including methods like chain transfer reactions, graft copolymerization, and using multifunctional monomers that induce branch points within the polymer structure. Advanced polymerization techniques such as atom transfer radical polymerization (ATRP) and reversible addition-fragmentation chain transfer (RAFT) enable precise control over branch density and architecture in branched polymers.

Physical Properties Comparison

Linear polymers exhibit higher density and crystallinity due to their closely packed molecular chains, resulting in greater tensile strength and melting points. Branched polymers have lower density and crystallinity because side chains prevent tight packing, which imparts increased flexibility and impact resistance. The presence of branches reduces polymer chain entanglement, leading to lower viscosity and easier processability in branched polymers compared to linear ones.

Mechanical Strength and Flexibility

Linear polymers exhibit higher tensile strength due to closely packed chains that promote strong intermolecular forces, enhancing mechanical integrity. Branched polymers have increased flexibility as branch points reduce chain packing density, allowing greater segmental mobility. The structural differences directly influence applications where either durability or pliability is critical.

Crystallinity and Melting Behavior

Linear polymers exhibit higher crystallinity due to their orderly, tightly packed chains, resulting in sharp melting points and enhanced mechanical strength. Branched polymers have irregular structures that disrupt chain packing, leading to lower crystallinity and broader, less defined melting transitions. This difference significantly affects polymer processing and end-use applications, with linear polymers favored for rigidity and branched polymers for flexibility and impact resistance.

Processing Techniques and Applications

Linear polymers exhibit higher density and crystallinity, making them ideal for extrusion and injection molding in applications like fibers and films. Branched polymers have lower density and reduced crystallinity, enhancing melt flow properties suited for blow molding and foam production. Processing techniques leverage the molecular structure to optimize products such as packaging materials from branched polymers and high-strength fibers from linear polymers.

Thermal Stability and Degradation

Linear polymers typically exhibit higher thermal stability due to their regular, closely packed molecular structure, which facilitates stronger intermolecular forces and higher melting points. Branched polymers show lower thermal stability and faster degradation rates as the branches create more free volume and reduce crystallinity, making them more susceptible to thermal motion and bond scission. The degradation mechanisms in branched polymers often involve chain scission at branch points, accelerating the breakdown process compared to the more robust backbone of linear polymers.

Impact on Polymer Performance

Linear polymers exhibit higher density and crystallinity due to their orderly chain alignment, resulting in superior tensile strength and chemical resistance. Branched polymers, with their irregular chain architecture, demonstrate lower density and increased elasticity, enhancing impact resistance and processability. The molecular structure directly influences thermal stability and mechanical properties, determining the polymer's suitability for specific applications.

Choosing Between Linear and Branched Polymers

Linear polymers exhibit high density and tensile strength due to their closely packed chains, making them ideal for applications requiring rigidity and durability. Branched polymers possess lower density and enhanced flexibility, which improves impact resistance and processability in products like elastomers and adhesives. Selecting between linear and branched polymers depends on desired mechanical properties and end-use performance criteria.

Linear Polymer vs Branched Polymer Infographic

materialdif.com

materialdif.com