Fiberglass Reinforced Polymer (FRP) offers cost-effective durability and corrosion resistance, making it ideal for applications requiring lightweight strength at a lower price point. Carbon Fiber Reinforced Polymer (CFRP) provides superior stiffness, tensile strength, and thermal stability, suitable for high-performance aerospace and automotive components. While CFRP outperforms in mechanical properties, FRP remains preferred for its affordability and ease of fabrication in construction and infrastructure projects.

Table of Comparison

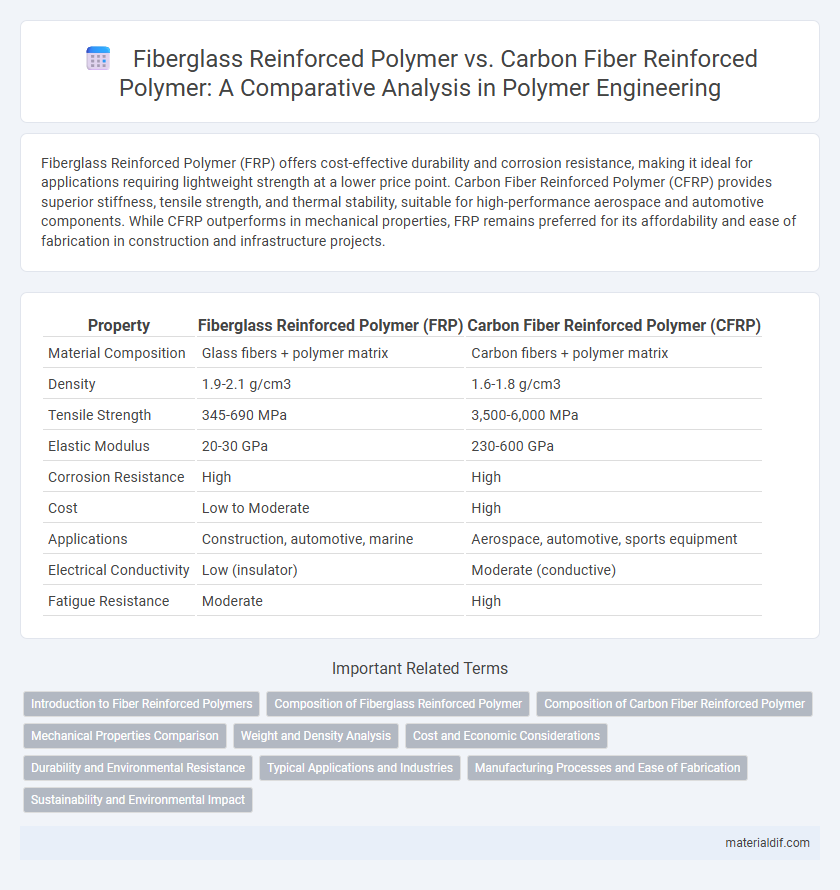

| Property | Fiberglass Reinforced Polymer (FRP) | Carbon Fiber Reinforced Polymer (CFRP) |

|---|---|---|

| Material Composition | Glass fibers + polymer matrix | Carbon fibers + polymer matrix |

| Density | 1.9-2.1 g/cm3 | 1.6-1.8 g/cm3 |

| Tensile Strength | 345-690 MPa | 3,500-6,000 MPa |

| Elastic Modulus | 20-30 GPa | 230-600 GPa |

| Corrosion Resistance | High | High |

| Cost | Low to Moderate | High |

| Applications | Construction, automotive, marine | Aerospace, automotive, sports equipment |

| Electrical Conductivity | Low (insulator) | Moderate (conductive) |

| Fatigue Resistance | Moderate | High |

Introduction to Fiber Reinforced Polymers

Fiber Reinforced Polymers (FRPs) consist of polymer matrices embedded with high-strength fibers to enhance mechanical properties such as tensile strength and stiffness. Fiberglass Reinforced Polymer (GFRP) utilizes glass fibers known for cost-effectiveness, corrosion resistance, and moderate strength, making it suitable for construction and automotive applications. Carbon Fiber Reinforced Polymer (CFRP) incorporates carbon fibers that offer superior strength-to-weight ratio, higher stiffness, and excellent fatigue resistance, primarily used in aerospace, high-performance sports, and advanced engineering sectors.

Composition of Fiberglass Reinforced Polymer

Fiberglass Reinforced Polymer (FRP) is composed of a polymer matrix, typically epoxy, polyester, or vinyl ester resin, embedded with glass fibers that provide tensile strength and flexibility. The glass fibers, usually E-glass or S-glass, are arranged in woven mats or continuous strands to enhance mechanical properties and resistance to corrosion. This composite structure offers a lightweight, cost-effective alternative with excellent impact resistance and electrical insulation compared to Carbon Fiber Reinforced Polymer (CFRP).

Composition of Carbon Fiber Reinforced Polymer

Carbon Fiber Reinforced Polymer (CFRP) consists primarily of carbon fibers embedded within a polymer matrix, typically epoxy resin, providing exceptional strength-to-weight ratio and high tensile strength compared to Fiberglass Reinforced Polymer (FRP). The carbon fibers, made from thin strands of carbon atoms bonded in a crystalline formation, offer superior stiffness and fatigue resistance, making CFRP ideal for aerospace, automotive, and high-performance applications. The polymer matrix in CFRP not only binds the fibers together but also protects them from environmental damage and distributes mechanical loads evenly.

Mechanical Properties Comparison

Fiberglass Reinforced Polymer (FRP) exhibits excellent tensile strength ranging from 340 to 900 MPa and a modulus of elasticity between 20 to 40 GPa, making it suitable for applications requiring high impact resistance and flexibility. Carbon Fiber Reinforced Polymer (CFRP) offers superior mechanical properties with tensile strength often exceeding 3,500 MPa and a modulus of elasticity up to 230 GPa, providing significantly higher stiffness and strength-to-weight ratio compared to FRP. While FRP is more cost-effective and corrosion-resistant, CFRP's enhanced fatigue resistance and lightweight characteristics make it ideal for aerospace and automotive structural components.

Weight and Density Analysis

Fiberglass Reinforced Polymer (FRP) typically weighs about 1.9 to 2.6 g/cm3, whereas Carbon Fiber Reinforced Polymer (CFRP) ranges from 1.6 to 1.8 g/cm3, making CFRP significantly lighter. The lower density of CFRP results in superior strength-to-weight ratio performance, beneficial in aerospace and automotive applications requiring high strength with minimal weight. FRP offers cost-effective solutions where weight is less critical, but CFRP remains the preferred choice when weight reduction and stiffness are paramount.

Cost and Economic Considerations

Fiberglass Reinforced Polymer (FRP) offers a more cost-effective solution compared to Carbon Fiber Reinforced Polymer (CFRP), with material costs typically 60-80% lower, making it ideal for large-scale applications and budget-sensitive projects. Despite CFRP's higher initial investment, its superior strength-to-weight ratio and durability translate to long-term savings in maintenance and performance efficiency. Economic considerations favor FRP for widespread use in construction and automotive industries, while CFRP remains preferred for high-performance aerospace and sports equipment where cost is secondary to material performance.

Durability and Environmental Resistance

Fiberglass Reinforced Polymer (FRP) offers excellent durability and high resistance to moisture, chemicals, and UV exposure, making it suitable for harsh environmental conditions. Carbon Fiber Reinforced Polymer (CFRP) provides superior mechanical strength and fatigue resistance but is more susceptible to environmental degradation from UV light and chemical exposure unless properly coated. Both materials exhibit strong corrosion resistance, yet CFRP's higher stiffness comes with increased sensitivity to environmental factors impacting long-term durability.

Typical Applications and Industries

Fiberglass Reinforced Polymer (FRP) is commonly used in construction, automotive, and marine industries due to its cost-effectiveness and corrosion resistance, making it ideal for structural panels, pipes, and boat hulls. Carbon Fiber Reinforced Polymer (CFRP) is preferred in aerospace, high-performance automotive, and sports equipment industries because of its superior strength-to-weight ratio and stiffness, enabling lightweight yet durable components such as aircraft parts, race car frames, and tennis rackets. Both materials serve critical roles in manufacturing, with FRP favored for large-scale, economical applications and CFRP chosen for high-performance, precision-engineered products.

Manufacturing Processes and Ease of Fabrication

Fiberglass Reinforced Polymer (FRP) typically involves simpler manufacturing processes such as hand lay-up, spray-up, or filament winding, which allows for easier and cost-effective fabrication, making it suitable for large-scale production. Carbon Fiber Reinforced Polymer (CFRP) requires more advanced manufacturing techniques like autoclave curing, pre-preg lay-up, or resin transfer molding, demanding precise temperature and pressure control to achieve optimal mechanical properties. The ease of fabrication favors fiberglass in terms of lower complexity and cost, while carbon fiber demands specialized equipment and skilled labor, impacting production time and expense.

Sustainability and Environmental Impact

Fiberglass Reinforced Polymer (FRP) offers greater recyclability and lower production energy compared to Carbon Fiber Reinforced Polymer (CFRP), making it a more sustainable choice for many applications. However, CFRP provides superior strength-to-weight ratio and longer lifespan, potentially reducing material consumption and waste over time. Both materials pose challenges in end-of-life disposal, highlighting the need for improved recycling technologies to mitigate environmental impact.

Fiberglass Reinforced Polymer vs Carbon Fiber Reinforced Polymer Infographic

materialdif.com

materialdif.com