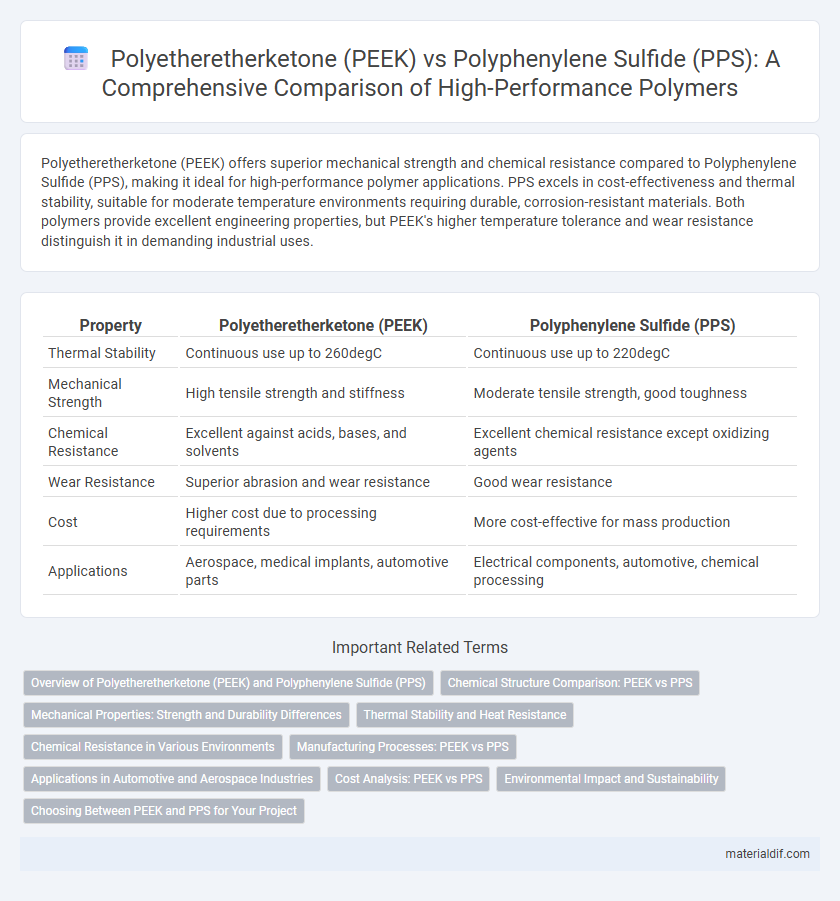

Polyetheretherketone (PEEK) offers superior mechanical strength and chemical resistance compared to Polyphenylene Sulfide (PPS), making it ideal for high-performance polymer applications. PPS excels in cost-effectiveness and thermal stability, suitable for moderate temperature environments requiring durable, corrosion-resistant materials. Both polymers provide excellent engineering properties, but PEEK's higher temperature tolerance and wear resistance distinguish it in demanding industrial uses.

Table of Comparison

| Property | Polyetheretherketone (PEEK) | Polyphenylene Sulfide (PPS) |

|---|---|---|

| Thermal Stability | Continuous use up to 260degC | Continuous use up to 220degC |

| Mechanical Strength | High tensile strength and stiffness | Moderate tensile strength, good toughness |

| Chemical Resistance | Excellent against acids, bases, and solvents | Excellent chemical resistance except oxidizing agents |

| Wear Resistance | Superior abrasion and wear resistance | Good wear resistance |

| Cost | Higher cost due to processing requirements | More cost-effective for mass production |

| Applications | Aerospace, medical implants, automotive parts | Electrical components, automotive, chemical processing |

Overview of Polyetheretherketone (PEEK) and Polyphenylene Sulfide (PPS)

Polyetheretherketone (PEEK) is a high-performance thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability, with a continuous service temperature up to 250degC. Polyphenylene Sulfide (PPS) offers excellent chemical resistance, dimensional stability, and inherent flame retardancy, maintaining performance at continuous use temperatures around 200degC. Both polymers are widely used in automotive, aerospace, and electronics industries due to their durability and resistance to harsh environments.

Chemical Structure Comparison: PEEK vs PPS

Polyetheretherketone (PEEK) features a linear aromatic polymer structure with repeating ether and ketone groups that provide excellent thermal stability and chemical resistance. Polyphenylene Sulfide (PPS) consists of a ring-shrinked polymer backbone with sulfide linkages between phenylene units, offering high chemical resistance and dimensional stability. The ketone groups in PEEK contribute to higher toughness and temperature resistance, while the sulfide bonds in PPS enhance resistance to oxidation and solvents.

Mechanical Properties: Strength and Durability Differences

Polyetheretherketone (PEEK) exhibits superior tensile strength, impact resistance, and fatigue endurance compared to Polyphenylene Sulfide (PPS), making it ideal for demanding mechanical applications. PPS, while offering good chemical resistance and thermal stability, shows lower strength and toughness relative to PEEK, limiting its use in high-stress environments. The enhanced mechanical durability of PEEK allows it to maintain performance under cyclic loading and elevated temperatures, outperforming PPS in long-term reliability.

Thermal Stability and Heat Resistance

Polyetheretherketone (PEEK) exhibits superior thermal stability with a continuous service temperature up to 260degC and a melting point around 343degC, making it ideal for high-temperature applications. Polyphenylene Sulfide (PPS) offers good heat resistance with a maximum service temperature near 200degC but has a lower melting point of approximately 280degC, limiting its use in extreme thermal environments. The high glass transition temperature (Tg) of PEEK, typically about 143degC, combined with its crystalline structure, ensures enhanced resistance to thermal degradation compared to PPS.

Chemical Resistance in Various Environments

Polyetheretherketone (PEEK) exhibits superior chemical resistance across a wide range of aggressive solvents, including acids, bases, and hydrocarbons, making it ideal for harsh chemical environments. Polyphenylene Sulfide (PPS) also offers excellent chemical resistance but tends to degrade under concentrated alkaline conditions and strong oxidizing agents. The enhanced thermal stability and resistance of PEEK in aggressive chemical environments provide a longer service life compared to PPS in demanding industrial applications.

Manufacturing Processes: PEEK vs PPS

Polyetheretherketone (PEEK) is typically processed using injection molding and compression molding, benefiting from its high melting point of approximately 343degC, which requires specialized high-temperature equipment. Polyphenylene Sulfide (PPS) offers greater processing versatility through injection molding, extrusion, and compression molding at a lower melting point near 285degC, enabling faster cycle times and reduced energy consumption. The manufacturing choice between PEEK and PPS hinges on thermal stability needs and equipment capabilities, with PEEK favored for high-performance applications requiring superior mechanical properties and PPS preferred for cost-effective, high-volume production.

Applications in Automotive and Aerospace Industries

Polyetheretherketone (PEEK) and Polyphenylene Sulfide (PPS) are high-performance polymers widely used in automotive and aerospace applications due to their excellent thermal stability and chemical resistance. PEEK offers superior mechanical strength and higher temperature tolerance up to 250degC, making it ideal for critical engine components and aerospace structural parts. PPS provides cost-effective corrosion resistance and dimensional stability, commonly applied in fuel system components and electrical connectors, balancing performance and economic efficiency in these industries.

Cost Analysis: PEEK vs PPS

Polyetheretherketone (PEEK) typically commands a higher price than Polyphenylene Sulfide (PPS) due to its superior mechanical properties and thermal stability, which justify the investment in high-performance applications. PPS offers a cost-effective alternative with excellent chemical resistance and dimensional stability, making it suitable for budget-sensitive projects requiring moderate performance. Evaluating lifecycle costs, including processing and maintenance, often reveals that PPS can reduce overall expenses despite PEEK's advanced material benefits.

Environmental Impact and Sustainability

Polyetheretherketone (PEEK) offers superior chemical resistance and mechanical properties but involves high energy consumption during production, resulting in a larger carbon footprint compared to Polyphenylene Sulfide (PPS). PPS demonstrates better recyclability and lower greenhouse gas emissions due to its less complex synthesis and lower processing temperatures. Both polymers contribute to sustainability efforts in high-performance applications, yet PPS currently presents a more environmentally friendly option due to its reduced environmental impact during manufacturing and end-of-life disposal.

Choosing Between PEEK and PPS for Your Project

Polyetheretherketone (PEEK) offers superior mechanical strength and high-temperature resistance up to 260degC, making it ideal for aerospace and medical applications requiring durability and chemical resistance. Polyphenylene Sulfide (PPS) provides excellent dimensional stability and chemical resistance at temperatures up to 240degC, often preferred for automotive and electrical components due to cost-effectiveness and flame retardancy. Selecting between PEEK and PPS depends on specific project demands such as thermal requirements, mechanical stress, and budget constraints to optimize performance and cost-efficiency.

Polyetheretherketone (PEEK) vs Polyphenylene Sulfide (PPS) Infographic

materialdif.com

materialdif.com