Glass-filled polymers offer enhanced mechanical strength, stiffness, and dimensional stability compared to unfilled polymers, making them ideal for high-performance applications. Unfilled polymers provide better flexibility, ease of processing, and improved surface finish, suitable for general-purpose uses where moderate strength suffices. Selecting between glass-filled and unfilled polymers depends on the required balance between reinforcement and processability in the final product.

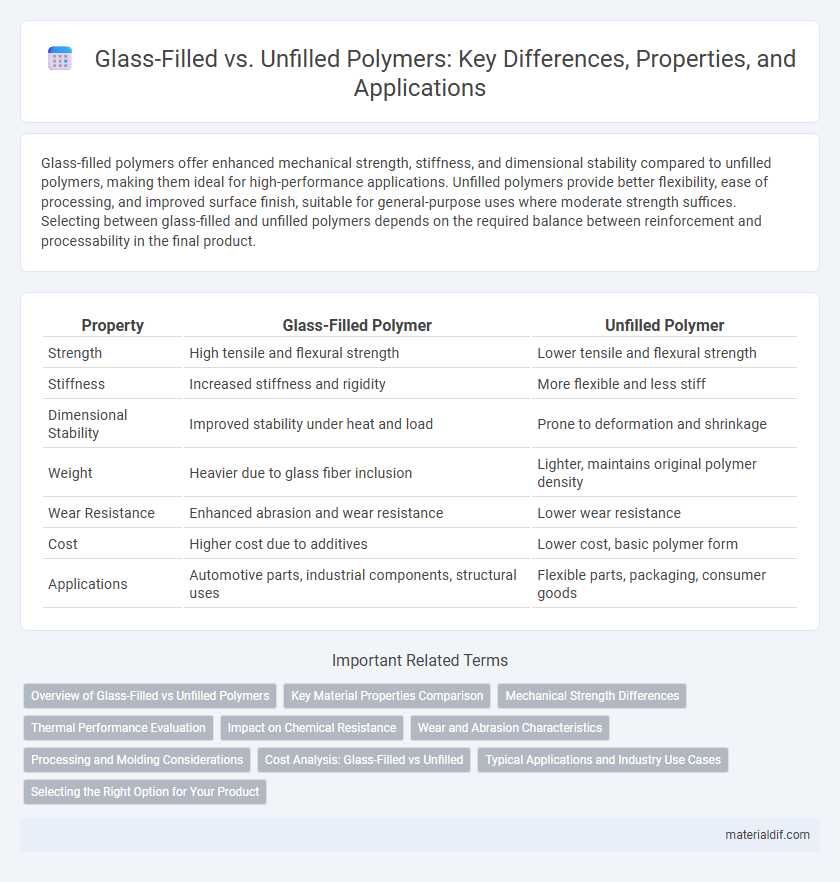

Table of Comparison

| Property | Glass-Filled Polymer | Unfilled Polymer |

|---|---|---|

| Strength | High tensile and flexural strength | Lower tensile and flexural strength |

| Stiffness | Increased stiffness and rigidity | More flexible and less stiff |

| Dimensional Stability | Improved stability under heat and load | Prone to deformation and shrinkage |

| Weight | Heavier due to glass fiber inclusion | Lighter, maintains original polymer density |

| Wear Resistance | Enhanced abrasion and wear resistance | Lower wear resistance |

| Cost | Higher cost due to additives | Lower cost, basic polymer form |

| Applications | Automotive parts, industrial components, structural uses | Flexible parts, packaging, consumer goods |

Overview of Glass-Filled vs Unfilled Polymers

Glass-filled polymers incorporate glass fibers to enhance mechanical strength, stiffness, and thermal resistance compared to unfilled polymers, which lack reinforcing materials. The addition of glass fibers significantly improves dimensional stability and impact resistance, making glass-filled polymers suitable for demanding applications like automotive and industrial components. Unfilled polymers offer greater flexibility, ease of processing, and lower cost, typically used when strength and rigidity are less critical.

Key Material Properties Comparison

Glass-filled polymers exhibit significantly enhanced tensile strength and stiffness compared to unfilled counterparts, owing to the reinforcement provided by glass fibers. Unfilled polymers offer superior impact resistance and better flexibility, making them suitable for applications requiring toughness and deformability. Thermal stability and dimensional accuracy are improved in glass-filled materials, while unfilled polymers generally provide better surface finish and ease of processing.

Mechanical Strength Differences

Glass-filled polymers exhibit significantly higher mechanical strength compared to unfilled polymers due to the reinforcement provided by glass fibers, which enhance tensile strength, rigidity, and impact resistance. The inclusion of glass fibers improves the polymer's load-bearing capacity and reduces deformation under stress, making glass-filled variants ideal for high-performance applications. Unfilled polymers, lacking this reinforcement, generally offer lower mechanical properties but may provide better flexibility and ease of processing.

Thermal Performance Evaluation

Glass-filled polymers exhibit significantly enhanced thermal stability and heat resistance compared to unfilled polymers, due to the high thermal conductivity and dimensional stability imparted by glass fibers. Unfilled polymers generally have lower heat deflection temperatures and can deform under prolonged thermal stress, limiting their application in high-temperature environments. The inclusion of glass fibers reduces thermal expansion and improves thermal conductivity, ensuring better performance in applications requiring sustained heat exposure.

Impact on Chemical Resistance

Glass-filled polymers exhibit superior chemical resistance compared to unfilled polymers due to the inert nature of glass fibers that enhance barrier properties and reduce permeability to corrosive agents. Unfilled polymers often show higher susceptibility to swelling, degradation, or chemical attack as their polymer matrix lacks reinforcement to impede chemical penetration. The presence of glass fibers also improves dimensional stability, preventing chemical-induced deformation and extending the service life of the composite material in harsh chemical environments.

Wear and Abrasion Characteristics

Glass-filled polymers exhibit significantly enhanced wear resistance and abrasion durability compared to unfilled polymers due to the inclusion of glass fibers, which reinforce the matrix and reduce material deformation under stress. The glass fibers improve surface hardness and reduce friction, leading to longer service life in applications involving repetitive motion or contact. Unfilled polymers typically show higher wear rates and quicker surface degradation, limiting their use in high-wear environments.

Processing and Molding Considerations

Glass-filled polymers offer enhanced rigidity and dimensional stability during processing, addressing challenges like warping and shrinkage that are more common in unfilled materials. Injection molding parameters for glass-filled polymers require higher screw torque and optimized melt temperatures to ensure uniform fiber dispersion and prevent fiber breakage. Unfilled polymers allow easier flow and faster cycle times but may need tighter process control to avoid defects such as sink marks and voids.

Cost Analysis: Glass-Filled vs Unfilled

Glass-filled polymers incur higher material costs due to the inclusion of reinforcing glass fibers, which enhance mechanical properties such as strength and rigidity but increase overall expense. Unfilled polymers generally offer lower costs, attributed to simpler production processes and absence of additives, making them economical for applications where high strength is not critical. Cost analysis must consider lifecycle expenses, as glass-filled materials often provide better durability and reduced maintenance, potentially offsetting initial price differences.

Typical Applications and Industry Use Cases

Glass-filled polymers enhance mechanical strength and thermal stability, making them ideal for automotive components, electrical housings, and industrial machinery parts requiring durability and heat resistance. Unfilled polymers offer flexibility, ease of molding, and cost efficiency, commonly used in consumer goods, packaging, and medical devices where impact resistance is less critical. The choice depends on performance requirements, with glass-filled grades favored in aerospace and automotive industries, while unfilled polymers dominate packaging and consumer product manufacturing.

Selecting the Right Option for Your Product

Glass-filled polymers offer enhanced mechanical strength, dimensional stability, and heat resistance compared to unfilled polymers, making them ideal for high-performance applications requiring durability and load-bearing capacity. Unfilled polymers provide greater flexibility, easier processing, and lower cost, suitable for products where impact resistance and cost efficiency are prioritized. Selecting the right option depends on the specific requirements of the product, such as strength, stiffness, thermal stability, and budget constraints.

Glass-Filled vs Unfilled Infographic

materialdif.com

materialdif.com