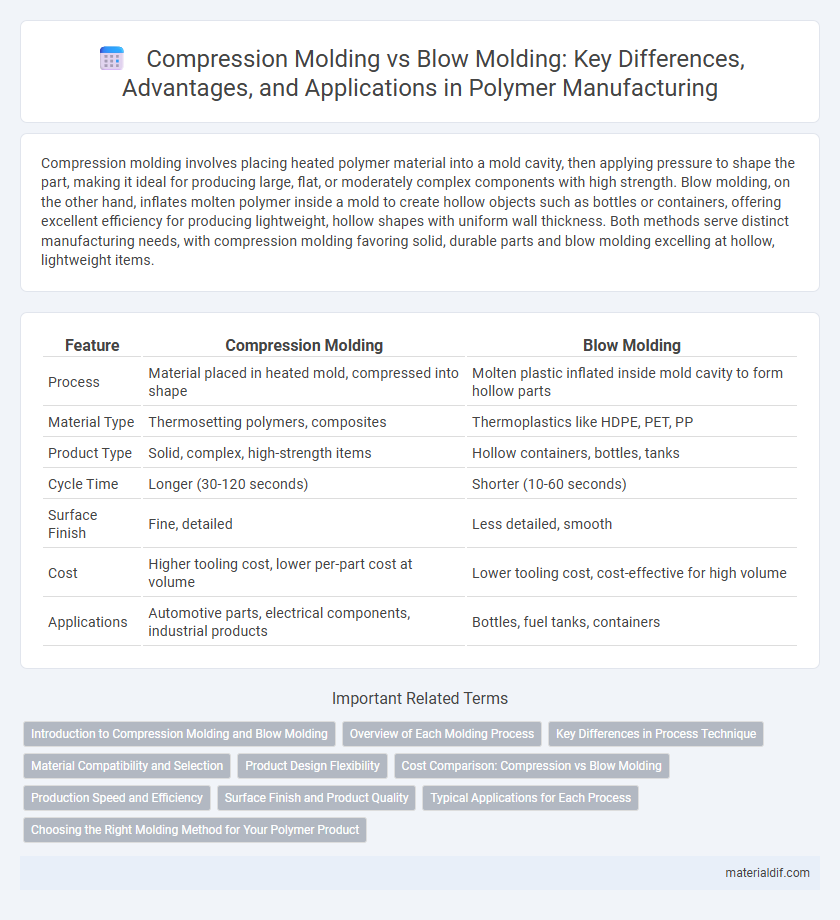

Compression molding involves placing heated polymer material into a mold cavity, then applying pressure to shape the part, making it ideal for producing large, flat, or moderately complex components with high strength. Blow molding, on the other hand, inflates molten polymer inside a mold to create hollow objects such as bottles or containers, offering excellent efficiency for producing lightweight, hollow shapes with uniform wall thickness. Both methods serve distinct manufacturing needs, with compression molding favoring solid, durable parts and blow molding excelling at hollow, lightweight items.

Table of Comparison

| Feature | Compression Molding | Blow Molding |

|---|---|---|

| Process | Material placed in heated mold, compressed into shape | Molten plastic inflated inside mold cavity to form hollow parts |

| Material Type | Thermosetting polymers, composites | Thermoplastics like HDPE, PET, PP |

| Product Type | Solid, complex, high-strength items | Hollow containers, bottles, tanks |

| Cycle Time | Longer (30-120 seconds) | Shorter (10-60 seconds) |

| Surface Finish | Fine, detailed | Less detailed, smooth |

| Cost | Higher tooling cost, lower per-part cost at volume | Lower tooling cost, cost-effective for high volume |

| Applications | Automotive parts, electrical components, industrial products | Bottles, fuel tanks, containers |

Introduction to Compression Molding and Blow Molding

Compression molding involves placing a polymer preform into a heated mold cavity where pressure is applied to shape and cure the material, making it ideal for thermosetting plastics and complex, high-strength parts. Blow molding uses air pressure to inflate a heated thermoplastic parison inside a mold, producing hollow parts like bottles and containers efficiently. Both methods optimize polymer thermoplastic processing but differ significantly in part geometry, production speed, and material properties.

Overview of Each Molding Process

Compression molding shapes thermosetting polymers by placing them into a heated mold cavity, applying pressure to cure and solidify the material into a dense, durable product ideal for automotive and electrical components. Blow molding forms hollow plastic parts, typically using thermoplastics like polyethylene or polypropylene, by inflating a heated parison inside a mold to create containers such as bottles and tanks. Both processes offer distinct advantages: compression molding excels in producing strong, complex geometries, while blow molding efficiently creates lightweight, hollow objects with uniform wall thickness.

Key Differences in Process Technique

Compression molding involves placing a polymer preform into a heated mold cavity and applying pressure to shape the material, ideal for thermosetting plastics and producing high-strength, detailed parts. Blow molding uses air pressure to inflate a softened polymer tube against the mold walls, commonly applied for hollow objects like bottles and containers made from thermoplastics. Key differences include compression molding's direct pressure shaping versus blow molding's air inflation, as well as the types of products and polymers suited for each process.

Material Compatibility and Selection

Compression molding is highly compatible with thermosetting polymers such as phenolics and epoxies, offering excellent dimensional stability and mechanical strength. Blow molding is primarily suited for thermoplastics like polyethylene and polypropylene, enabling the production of hollow and complex shapes with lightweight properties. Material selection depends on the polymer's thermal behavior and end-use requirements, where compression molding favors heat-resistant materials and blow molding prioritizes flexibility and impact resistance.

Product Design Flexibility

Compression molding offers limited product design flexibility due to its reliance on predetermined molds and pressure application, making it ideal for simple, solid shapes with uniform thickness. Blow molding provides greater design versatility, enabling the production of hollow, complex, and lightweight structures with variable wall thickness. Designers favor blow molding when intricate shapes and functional features such as handles or contours are required, enhancing both aesthetics and utility.

Cost Comparison: Compression vs Blow Molding

Compression molding generally offers lower tooling and material costs, making it cost-effective for producing small to medium-sized polymer parts with simple geometries. Blow molding typically incurs higher initial tooling expenses due to complex mold designs but provides greater efficiency and lower per-unit costs in high-volume production of hollow parts like bottles. Overall, compression molding is more economical for low-volume runs, whereas blow molding becomes cost-advantageous as production scale increases.

Production Speed and Efficiency

Compression molding typically offers slower production speeds compared to blow molding due to its batch processing nature and longer cycle times. Blow molding excels in efficiency for producing hollow plastic parts, enabling high-speed continuous manufacturing ideal for bottles and containers. The choice between these methods depends heavily on the required production volume and part complexity, with blow molding favored for rapid, large-scale output.

Surface Finish and Product Quality

Compression molding produces parts with superior surface finish and high dimensional accuracy due to the controlled pressure and heat applied during the process. Blow molding typically results in products with thinner walls and less precise surface textures, often requiring secondary finishing for enhanced quality. The choice between compression molding and blow molding depends on the desired surface smoothness and structural integrity of the polymer product.

Typical Applications for Each Process

Compression molding is commonly used for manufacturing high-strength automotive parts, electrical components, and household appliance casings due to its ability to mold thermosetting polymers with precision and durability. Blow molding is ideal for producing hollow plastic containers such as bottles, fuel tanks, and drums because it efficiently forms uniform, lightweight structures from thermoplastic materials. Each process serves distinct industrial applications based on shape complexity, material properties, and production volume requirements.

Choosing the Right Molding Method for Your Polymer Product

Compression molding excels in producing high-strength, durable polymer parts with complex geometries and thick walls, making it ideal for thermosets and reinforced composites. Blow molding is best suited for creating hollow, lightweight plastic containers with uniform wall thickness, commonly used with thermoplastics such as polyethylene and polypropylene. Selecting the right molding method depends on the product's design requirements, material type, and desired mechanical properties for optimal performance and cost efficiency.

Compression Molding vs Blow Molding Infographic

materialdif.com

materialdif.com