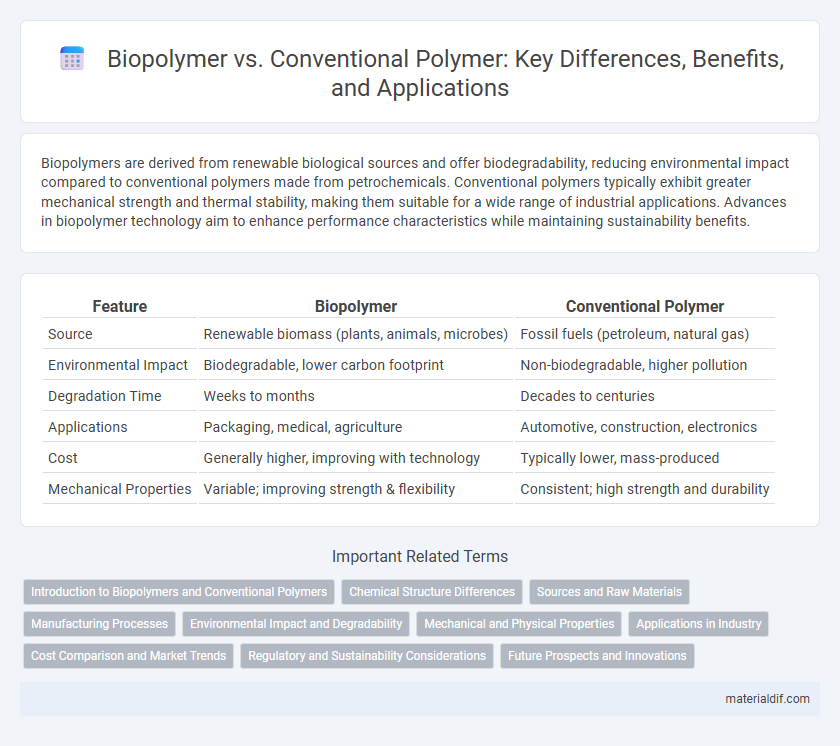

Biopolymers are derived from renewable biological sources and offer biodegradability, reducing environmental impact compared to conventional polymers made from petrochemicals. Conventional polymers typically exhibit greater mechanical strength and thermal stability, making them suitable for a wide range of industrial applications. Advances in biopolymer technology aim to enhance performance characteristics while maintaining sustainability benefits.

Table of Comparison

| Feature | Biopolymer | Conventional Polymer |

|---|---|---|

| Source | Renewable biomass (plants, animals, microbes) | Fossil fuels (petroleum, natural gas) |

| Environmental Impact | Biodegradable, lower carbon footprint | Non-biodegradable, higher pollution |

| Degradation Time | Weeks to months | Decades to centuries |

| Applications | Packaging, medical, agriculture | Automotive, construction, electronics |

| Cost | Generally higher, improving with technology | Typically lower, mass-produced |

| Mechanical Properties | Variable; improving strength & flexibility | Consistent; high strength and durability |

Introduction to Biopolymers and Conventional Polymers

Biopolymers are natural polymers derived from renewable biological sources such as plants, animals, and microorganisms, offering biodegradability and eco-friendly alternatives to synthetic materials. Conventional polymers, typically synthesized from petrochemical feedstocks, exhibit durability and versatility but pose environmental challenges due to their non-biodegradable nature. The growing demand for sustainable materials drives innovation in biopolymer applications spanning packaging, medical devices, and textiles.

Chemical Structure Differences

Biopolymers, derived from natural sources like plants and microorganisms, exhibit chemical structures primarily composed of repeating units such as sugars, amino acids, and nucleotides, resulting in biodegradability and biocompatibility. Conventional polymers, synthesized from petrochemical monomers like ethylene, propylene, and styrene, feature carbon-carbon backbone chains with functional groups tailored for durability and resistance to environmental degradation. The distinct chemical compositions influence properties such as molecular weight distribution, crystallinity, and thermal stability, driving applications across sustainable materials and industrial plastics.

Sources and Raw Materials

Biopolymers are derived from renewable biological sources such as plants, algae, and microorganisms, utilizing raw materials like starch, cellulose, and proteins. Conventional polymers rely on petrochemical feedstocks obtained from fossil fuels, including crude oil and natural gas, as primary raw materials. The distinction in sources impacts sustainability, biodegradability, and environmental footprint between biopolymers and conventional polymers.

Manufacturing Processes

Biopolymers are primarily produced through biological processes such as fermentation, extraction from renewable resources, and enzymatic polymerization, which emphasize sustainability and lower carbon footprints. Conventional polymers rely on petrochemical-based manufacturing involving polymerization techniques like addition and condensation polymerization conducted under high temperature and pressure conditions. The choice of manufacturing process directly impacts the environmental footprint, scalability, and material properties of the resulting polymer.

Environmental Impact and Degradability

Biopolymers, derived from renewable biomass sources such as starch, cellulose, and proteins, significantly reduce reliance on fossil fuels and lower greenhouse gas emissions compared to conventional polymers made from petrochemicals. Their inherent biodegradability enables natural decomposition through microbial activity, minimizing persistent plastic pollution and facilitating composting in industrial or home settings. Conventional polymers, characterized by long-lasting carbon chains, resist degradation and often accumulate in landfills and oceans, posing substantial environmental hazards over decades.

Mechanical and Physical Properties

Biopolymers typically exhibit lower tensile strength and thermal stability compared to conventional polymers, limiting their use in high-performance applications. However, biopolymers offer superior biodegradability and reduced environmental impact, making them ideal for sustainable packaging and biomedical devices. Conventional polymers, such as polyethylene and polystyrene, provide enhanced durability, chemical resistance, and consistent mechanical properties necessary for industrial manufacturing.

Applications in Industry

Biopolymers are increasingly utilized in the packaging, biomedical, and agriculture industries due to their biodegradability and reduced environmental impact, offering sustainable alternatives to conventional polymers. Conventional polymers dominate automotive, construction, and electronics sectors because of their superior mechanical strength, thermal resistance, and cost-effectiveness. The shift towards biopolymers is driven by stringent environmental regulations and growing consumer demand for eco-friendly materials in industrial applications.

Cost Comparison and Market Trends

Biopolymers generally have higher production costs than conventional polymers due to raw material expenses and less established manufacturing processes. Market trends indicate increasing demand for biopolymers driven by environmental regulations and consumer preference for sustainable products, which is gradually improving their cost competitiveness. Conventional polymers dominate in large-scale industrial applications due to lower costs and well-developed supply chains, but biopolymers are rapidly expanding in packaging and biomedical sectors.

Regulatory and Sustainability Considerations

Biopolymers are favored in regulatory frameworks due to their biodegradability and reduced environmental impact, aligning with increasing global sustainability mandates such as the EU's Plastic Strategy. Conventional polymers, primarily derived from fossil fuels, face stricter regulations aimed at reducing carbon emissions and plastic waste accumulation in ecosystems. Sustainable policies promote biopolymer adoption by encouraging renewable feedstocks and lifecycle assessments that demonstrate lower ecological footprints compared to traditional polymers.

Future Prospects and Innovations

Biopolymers are gaining significant traction due to their sustainability, biodegradability, and reduced environmental impact, positioning them as key materials for future innovations in packaging, medical applications, and agriculture. Conventional polymers, derived primarily from fossil fuels, face challenges related to pollution and resource depletion, driving research towards hybrid materials and enhanced recycling technologies to improve their lifecycle. Emerging advancements in enzymatic synthesis, bio-based monomers, and nanocomposite biopolymers promise to accelerate the development of eco-friendly alternatives with comparable performance to traditional polymers.

Biopolymer vs Conventional Polymer Infographic

materialdif.com

materialdif.com