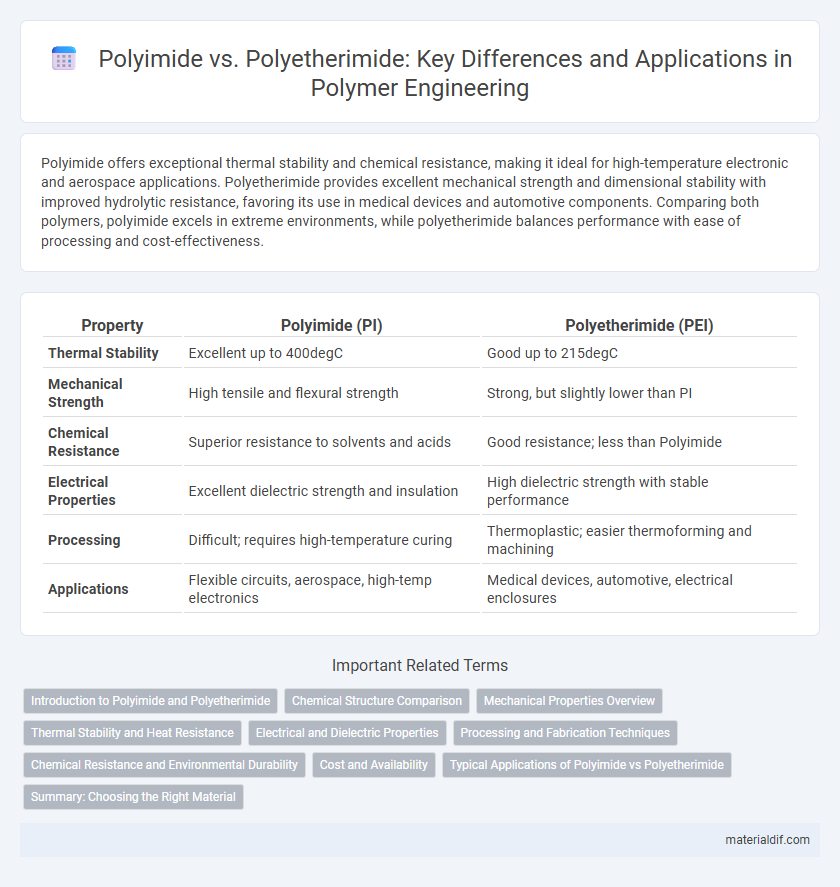

Polyimide offers exceptional thermal stability and chemical resistance, making it ideal for high-temperature electronic and aerospace applications. Polyetherimide provides excellent mechanical strength and dimensional stability with improved hydrolytic resistance, favoring its use in medical devices and automotive components. Comparing both polymers, polyimide excels in extreme environments, while polyetherimide balances performance with ease of processing and cost-effectiveness.

Table of Comparison

| Property | Polyimide (PI) | Polyetherimide (PEI) |

|---|---|---|

| Thermal Stability | Excellent up to 400degC | Good up to 215degC |

| Mechanical Strength | High tensile and flexural strength | Strong, but slightly lower than PI |

| Chemical Resistance | Superior resistance to solvents and acids | Good resistance; less than Polyimide |

| Electrical Properties | Excellent dielectric strength and insulation | High dielectric strength with stable performance |

| Processing | Difficult; requires high-temperature curing | Thermoplastic; easier thermoforming and machining |

| Applications | Flexible circuits, aerospace, high-temp electronics | Medical devices, automotive, electrical enclosures |

Introduction to Polyimide and Polyetherimide

Polyimide is a high-performance polymer known for its thermal stability, chemical resistance, and excellent mechanical properties, often used in aerospace and electronics. Polyetherimide is a subset of polyimides that incorporates ether linkages, enhancing its toughness, impact resistance, and ease of processing. Both polymers serve critical roles in advanced engineering applications requiring durability under extreme conditions.

Chemical Structure Comparison

Polyimide features aromatic imide linkages known for exceptional thermal stability and chemical resistance, while polyetherimide incorporates flexible ether groups within its backbone, enhancing toughness and processability. The rigid imide rings in polyimide provide high glass transition temperatures up to 400degC, contrasting with polyetherimide's lower Tg around 215degC due to the ether segment flexibility. This structural difference impacts solvent resistance, with polyimide exhibiting superior chemical inertness compared to the more hydrolytically sensitive polyetherimide.

Mechanical Properties Overview

Polyimide demonstrates exceptional mechanical strength and thermal stability, maintaining rigidity at temperatures up to 400degC, making it suitable for high-performance applications requiring durable materials. Polyetherimide offers superior impact resistance and enhanced toughness while retaining excellent dimensional stability at elevated temperatures around 170-210degC. Both polymers exhibit outstanding tensile strength, but polyetherimide's flexibility and resistance to stress cracking provide advantages in dynamic or shock-loading environments.

Thermal Stability and Heat Resistance

Polyimide exhibits exceptional thermal stability with continuous use temperatures exceeding 400degC, making it suitable for extreme heat applications. Polyetherimide offers high heat resistance with a glass transition temperature around 217degC, providing reliable performance in high-temperature environments but below the threshold of traditional polyimides. The superior thermal endurance of polyimide makes it ideal for aerospace and electronics, while polyetherimide suits demanding engineering applications requiring toughness and heat resistance.

Electrical and Dielectric Properties

Polyimide exhibits excellent electrical insulation and high dielectric strength, making it ideal for microelectronics and flexible circuits. Polyetherimide offers superior dielectric constant stability and higher volume resistivity, enhancing performance in advanced electrical components. Both polymers maintain low dielectric loss, but polyetherimide provides better thermal stability for high-temperature electrical applications.

Processing and Fabrication Techniques

Polyimide offers exceptional thermal stability and chemical resistance, making it suitable for high-temperature applications achievable through techniques like film casting and precision molding. Polyetherimide provides superior toughness and dimensional stability, often processed through injection molding and extrusion methods to fabricate complex, high-strength components. Both polymers demand controlled curing cycles and specialized equipment to optimize mechanical properties and ensure consistent part quality during fabrication.

Chemical Resistance and Environmental Durability

Polyimide exhibits superior chemical resistance, with high tolerance to solvents, acids, and bases, making it ideal for harsh chemical environments. Polyetherimide offers enhanced environmental durability, including excellent hydrolytic stability and resistance to moisture absorption, which ensures long-term performance in humid or wet conditions. Both materials perform well in high-temperature applications, but Polyimide's resilient aromatic backbone provides greater resistance to oxidative degradation.

Cost and Availability

Polyimide generally offers higher thermal stability but comes with a higher cost and limited availability compared to polyetherimide, which is more cost-effective and readily accessible. Polyetherimide provides a balanced performance with good mechanical properties and easier processing, making it a popular choice for applications requiring a thermoplastic with reliable durability. Manufacturers often prefer polyetherimide in high-volume production due to its lower price and widespread supply chain presence.

Typical Applications of Polyimide vs Polyetherimide

Polyimide is commonly used in high-temperature electrical insulation, flexible printed circuit boards, and aerospace components due to its exceptional thermal stability and chemical resistance. Polyetherimide is favored in medical devices, automotive parts, and electrical housings for its flame retardancy, high strength, and excellent dimensional stability. Both polymers serve critical roles in advanced engineering applications requiring durability and performance under demanding conditions.

Summary: Choosing the Right Material

Polyimide offers excellent thermal stability and chemical resistance, making it ideal for high-temperature applications such as aerospace and electronics. Polyetherimide provides superior toughness and dimensional stability at elevated temperatures, suitable for structural components and medical devices. Selecting between these polymers depends on the balance between thermal endurance and mechanical performance required for the specific application.

Polyimide vs Polyetherimide Infographic

materialdif.com

materialdif.com