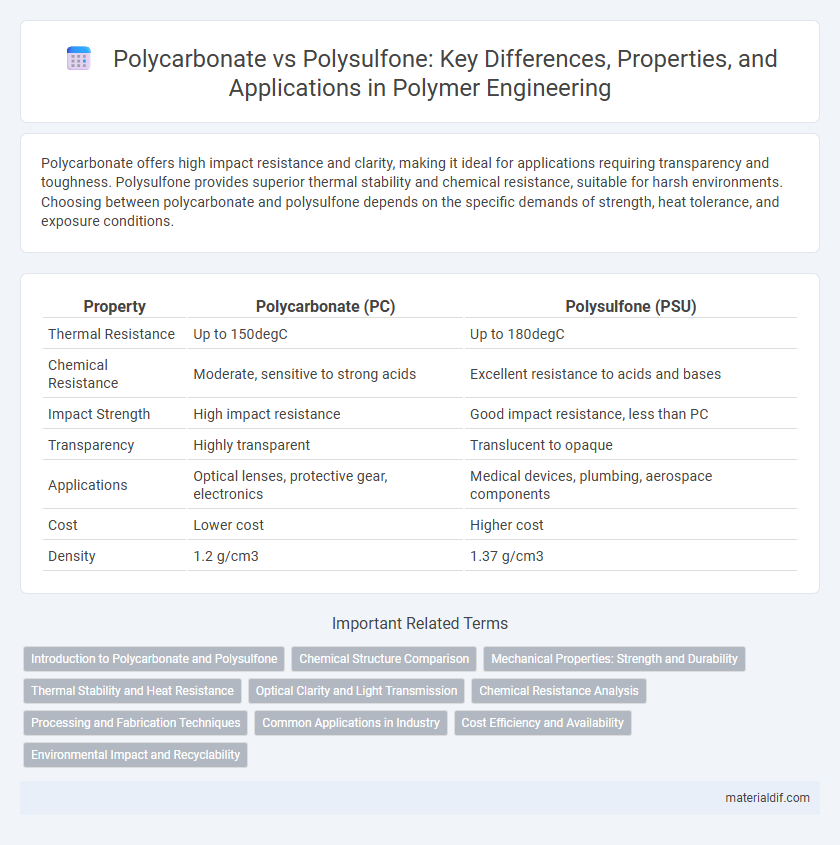

Polycarbonate offers high impact resistance and clarity, making it ideal for applications requiring transparency and toughness. Polysulfone provides superior thermal stability and chemical resistance, suitable for harsh environments. Choosing between polycarbonate and polysulfone depends on the specific demands of strength, heat tolerance, and exposure conditions.

Table of Comparison

| Property | Polycarbonate (PC) | Polysulfone (PSU) |

|---|---|---|

| Thermal Resistance | Up to 150degC | Up to 180degC |

| Chemical Resistance | Moderate, sensitive to strong acids | Excellent resistance to acids and bases |

| Impact Strength | High impact resistance | Good impact resistance, less than PC |

| Transparency | Highly transparent | Translucent to opaque |

| Applications | Optical lenses, protective gear, electronics | Medical devices, plumbing, aerospace components |

| Cost | Lower cost | Higher cost |

| Density | 1.2 g/cm3 | 1.37 g/cm3 |

Introduction to Polycarbonate and Polysulfone

Polycarbonate is a durable, transparent thermoplastic known for its high impact resistance, optical clarity, and heat resistance, making it ideal for applications like eyewear lenses and electronic components. Polysulfone is a high-performance polymer characterized by excellent thermal stability, chemical resistance, and toughness, commonly used in medical devices and membranes. Both polymers offer distinct mechanical and thermal properties that cater to specialized industrial needs.

Chemical Structure Comparison

Polycarbonate features carbonate groups (-O-(C=O)-O-) linking bisphenol A units, resulting in a rigid, transparent thermoplastic with strong impact resistance. Polysulfone contains aromatic ether and sulfone groups (-SO2-) within its backbone, contributing to superior thermal stability and chemical resistance compared to polycarbonate. The presence of sulfone groups in polysulfone enhances oxidative stability, while polycarbonate's structure provides greater flexibility and clarity.

Mechanical Properties: Strength and Durability

Polycarbonate exhibits high impact strength and excellent toughness, making it highly resistant to cracking and breaking under stress, while polysulfone offers superior thermal stability combined with good mechanical strength, maintaining integrity at elevated temperatures. The tensile strength of polycarbonate ranges from 60 to 70 MPa, whereas polysulfone typically has a tensile strength between 55 and 75 MPa, with polysulfone outperforming polycarbonate in long-term durability under harsh environmental conditions. Both polymers provide robust mechanical performance, but polycarbonate is favored for impact resistance, and polysulfone is preferred for applications requiring sustained strength and durability at higher temperatures.

Thermal Stability and Heat Resistance

Polycarbonate exhibits a glass transition temperature around 147degC, providing moderate thermal stability and heat resistance suitable for everyday applications. Polysulfone, with a higher glass transition temperature near 190degC, offers superior thermal stability and can withstand prolonged exposure to elevated temperatures without significant degradation. This enhanced heat resistance makes polysulfone ideal for demanding environments requiring sustained high-temperature performance.

Optical Clarity and Light Transmission

Polycarbonate exhibits superior optical clarity with light transmission rates around 88-90%, making it ideal for applications requiring clear visibility. Polysulfone offers moderate clarity with light transmission closer to 75-80%, often used where chemical resistance is prioritized over transparency. The higher light transmission of polycarbonate enhances its suitability for lenses and optical components compared to polysulfone.

Chemical Resistance Analysis

Polycarbonate exhibits moderate chemical resistance, with vulnerability to strong acids, bases, and organic solvents, limiting its application in highly corrosive environments. Polysulfone demonstrates superior chemical resistance, maintaining stability against a wider range of chemicals, including strong acids, bases, and polar solvents, making it suitable for demanding industrial and medical uses. The inherent aromatic sulfone groups in polysulfone enhance its resistance to hydrolysis and oxidative degradation compared to the carbonate linkages in polycarbonate.

Processing and Fabrication Techniques

Polycarbonate offers excellent thermoforming capabilities, allowing it to be easily molded, extruded, and injection molded with high precision and clarity. Polysulfone exhibits superior thermal stability during fabrication, making it suitable for high-temperature processes such as steam sterilization and chemical resistant applications, though it requires higher processing temperatures and specialized equipment. Both polymers enable advanced fabrication techniques, but polycarbonate's ease of processing favors rapid prototyping and consumer goods, whereas polysulfone is preferred for demanding industrial and medical device manufacturing.

Common Applications in Industry

Polycarbonate is widely used in optical media, automotive components, and electronic housings due to its high impact resistance and clarity. Polysulfone finds common applications in medical devices, membrane filters, and aerospace parts, benefiting from its superior thermal stability and chemical resistance. Both polymers are essential in industries requiring durable, high-performance materials with specific mechanical and thermal properties.

Cost Efficiency and Availability

Polycarbonate offers higher cost efficiency due to its widespread availability and lower production costs compared to polysulfone, making it a preferred choice in budget-sensitive applications. Polysulfone, though more expensive, provides superior thermal stability and chemical resistance, justifying its use in specialized industries despite limited availability. The broader market presence of polycarbonate drives competitive pricing, while polysulfone's niche status results in higher material costs and constrained supply.

Environmental Impact and Recyclability

Polycarbonate and polysulfone differ significantly in environmental impact and recyclability, with polycarbonate generally offering better recyclability through established mechanical recycling processes, reducing landfill waste. Polysulfone, known for its thermal stability and chemical resistance, poses greater recycling challenges due to its complex polymer structure, resulting in limited industrial recycling options. Both polymers' environmental footprints depend on production energy intensity and end-of-life management, but polycarbonate's broader recycling infrastructure supports a more sustainable lifecycle.

Polycarbonate vs Polysulfone Infographic

materialdif.com

materialdif.com