Additive manufacturing enables the creation of complex polymer geometries layer by layer, offering high design flexibility and rapid prototyping with minimal material waste. Compression molding involves pressing polymer materials into shaped molds under heat and pressure, producing high-strength parts suitable for large-scale production with consistent quality. While additive manufacturing excels in customization and low-volume runs, compression molding is preferred for cost-effective mass manufacturing of durable polymer components.

Table of Comparison

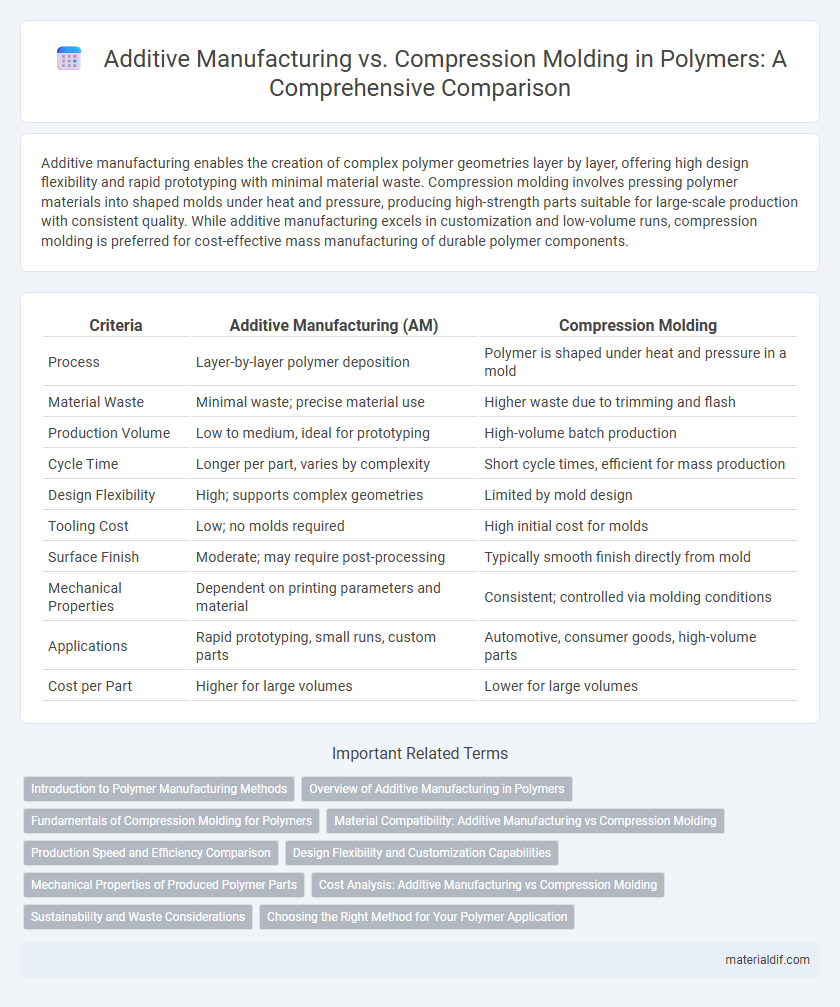

| Criteria | Additive Manufacturing (AM) | Compression Molding |

|---|---|---|

| Process | Layer-by-layer polymer deposition | Polymer is shaped under heat and pressure in a mold |

| Material Waste | Minimal waste; precise material use | Higher waste due to trimming and flash |

| Production Volume | Low to medium, ideal for prototyping | High-volume batch production |

| Cycle Time | Longer per part, varies by complexity | Short cycle times, efficient for mass production |

| Design Flexibility | High; supports complex geometries | Limited by mold design |

| Tooling Cost | Low; no molds required | High initial cost for molds |

| Surface Finish | Moderate; may require post-processing | Typically smooth finish directly from mold |

| Mechanical Properties | Dependent on printing parameters and material | Consistent; controlled via molding conditions |

| Applications | Rapid prototyping, small runs, custom parts | Automotive, consumer goods, high-volume parts |

| Cost per Part | Higher for large volumes | Lower for large volumes |

Introduction to Polymer Manufacturing Methods

Additive manufacturing in polymer production allows for layer-by-layer construction, enabling complex geometries and rapid prototyping with minimal material waste. Compression molding involves placing polymer material into a heated mold cavity, applying pressure to shape the part, which is ideal for high-volume production of durable components. Both methods offer distinct advantages in polymer manufacturing, with additive manufacturing excelling in customization and compression molding providing efficient mass production.

Overview of Additive Manufacturing in Polymers

Additive manufacturing in polymers enables precise layer-by-layer fabrication of complex geometries with minimal material waste, leveraging technologies such as fused deposition modeling (FDM) and stereolithography (SLA). This process supports rapid prototyping and customization by directly converting digital models into physical parts, enhancing design flexibility compared to traditional compression molding. Polymer additive manufacturing materials range from thermoplastics like ABS and PLA to advanced photopolymers, offering diverse mechanical and thermal properties tailored for specific applications.

Fundamentals of Compression Molding for Polymers

Compression molding for polymers involves placing a pre-measured polymer charge into a heated mold cavity, which is then closed and subjected to high pressure to shape the material. The process relies on heat and pressure to soften and cure thermosetting polymers or thermoplastics, resulting in accurate dimensional control and enhanced mechanical properties. This technique is ideal for producing large, complex shapes with consistent quality, making it a fundamental method in polymer manufacturing.

Material Compatibility: Additive Manufacturing vs Compression Molding

Additive manufacturing supports a wide range of thermoplastics, thermosets, and composites, enabling complex geometries and lightweight designs that are often unattainable with traditional methods. Compression molding primarily utilizes thermoset polymers and high-performance composites, offering superior mechanical strength and thermal resistance suitable for high-volume production. Material compatibility in additive manufacturing favors design flexibility and rapid prototyping, whereas compression molding excels in consistent part quality and structural integrity for large-scale manufacturing.

Production Speed and Efficiency Comparison

Additive manufacturing in polymer production allows rapid prototyping with minimal material waste, significantly accelerating the development phase compared to compression molding, which involves longer cycle times due to heating and cooling stages. Compression molding offers higher efficiency for large-scale production runs because it produces consistent, high-strength parts with less post-processing, making it suitable for mass manufacturing. While additive manufacturing excels in customization and quick iteration, compression molding remains superior in throughput and cost-efficiency for bulk polymer component fabrication.

Design Flexibility and Customization Capabilities

Additive manufacturing offers superior design flexibility and customization capabilities compared to compression molding, enabling the production of complex geometries and intricate lattice structures without the need for specialized tooling. Compression molding, while efficient for high-volume production of consistent polymer parts, is limited by mold design constraints that restrict variations and intricate detailing. This makes additive manufacturing ideal for prototyping, low-volume customized polymer components, and applications requiring rapid iteration and tailored mechanical properties.

Mechanical Properties of Produced Polymer Parts

Additive manufacturing produces polymer parts with anisotropic mechanical properties, often exhibiting lower tensile strength and impact resistance compared to compression molding. Compression molding yields polymer components with superior uniformity, higher density, and enhanced mechanical performance, including improved flexural strength and hardness. Optimizing process parameters in additive manufacturing can partially reduce disparities, but compression molding remains the preferred method for critical load-bearing polymer applications.

Cost Analysis: Additive Manufacturing vs Compression Molding

Additive manufacturing incurs higher per-unit costs due to longer production times and expensive raw materials, making it less cost-effective for large-scale polymer parts. Compression molding offers lower costs through efficient mass production, reduced material waste, and faster cycle times, ideal for high-volume polymer component manufacturing. Cost analysis reveals that additive manufacturing suits prototyping and low-volume runs, while compression molding excels in affordability for bulk polymer production.

Sustainability and Waste Considerations

Additive manufacturing in polymer production significantly reduces material waste by precisely depositing only the required amount of polymer, leading to enhanced sustainability compared to compression molding, which often generates excess scrap due to trimming and flash. Polymer additive manufacturing supports closed-loop recycling by enabling the reuse of unused powder or filament, whereas compression molding's waste materials typically require energy-intensive disposal processes. The energy efficiency of additive manufacturing, combined with its ability to minimize carbon footprint through optimized material usage, positions it as a more sustainable solution in polymer component fabrication relative to traditional compression molding methods.

Choosing the Right Method for Your Polymer Application

Selecting the appropriate manufacturing method for polymer applications depends on factors such as production volume, part complexity, and material properties. Additive manufacturing excels in producing intricate geometries and rapid prototyping with minimal material waste, making it ideal for low-volume, customized parts. Compression molding is preferred for high-volume production due to its efficiency, consistent quality, and suitability for thermosetting polymers requiring high mechanical strength.

Additive Manufacturing vs Compression Molding Infographic

materialdif.com

materialdif.com