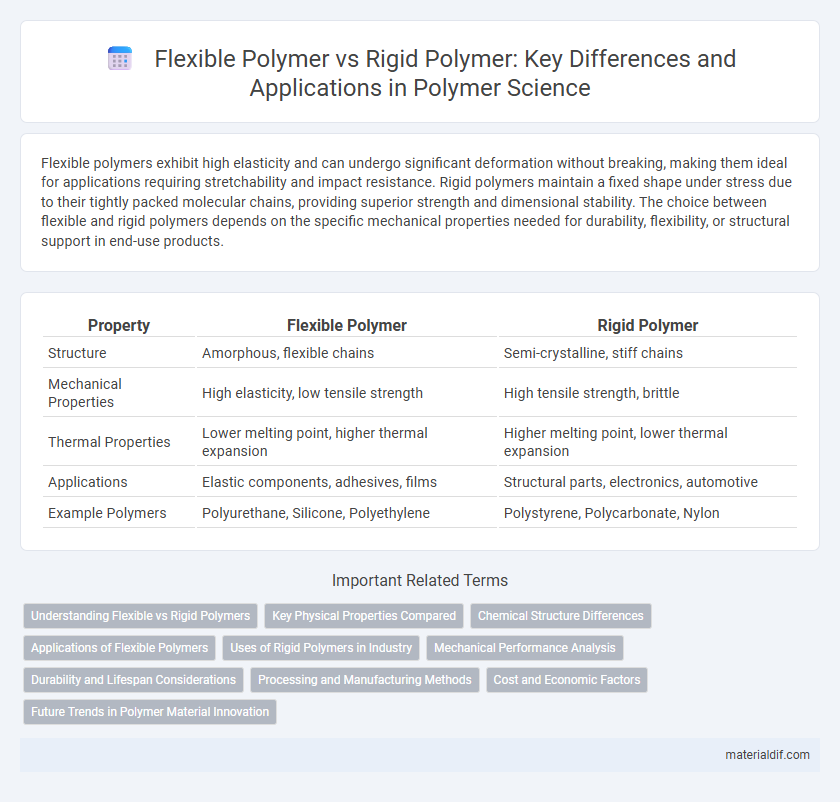

Flexible polymers exhibit high elasticity and can undergo significant deformation without breaking, making them ideal for applications requiring stretchability and impact resistance. Rigid polymers maintain a fixed shape under stress due to their tightly packed molecular chains, providing superior strength and dimensional stability. The choice between flexible and rigid polymers depends on the specific mechanical properties needed for durability, flexibility, or structural support in end-use products.

Table of Comparison

| Property | Flexible Polymer | Rigid Polymer |

|---|---|---|

| Structure | Amorphous, flexible chains | Semi-crystalline, stiff chains |

| Mechanical Properties | High elasticity, low tensile strength | High tensile strength, brittle |

| Thermal Properties | Lower melting point, higher thermal expansion | Higher melting point, lower thermal expansion |

| Applications | Elastic components, adhesives, films | Structural parts, electronics, automotive |

| Example Polymers | Polyurethane, Silicone, Polyethylene | Polystyrene, Polycarbonate, Nylon |

Understanding Flexible vs Rigid Polymers

Flexible polymers exhibit high molecular chain mobility, allowing them to bend and stretch without breaking, which makes them ideal for applications requiring elasticity and toughness. Rigid polymers have tightly packed, highly crystalline structures resulting in limited chain movement, leading to materials with high strength and dimensional stability but reduced flexibility. Understanding the molecular architecture and thermal properties of flexible versus rigid polymers is crucial for selecting the appropriate polymer type in product design and engineering applications.

Key Physical Properties Compared

Flexible polymers exhibit low glass transition temperatures (Tg) and high elongation at break, enabling significant deformation without fracture. Rigid polymers possess high Tg and tensile strength, maintaining dimensional stability under stress but with limited flexibility. The disparity in molecular chain mobility directly influences impact resistance, thermal stability, and elasticity between these polymer types.

Chemical Structure Differences

Flexible polymers possess long, coiled molecular chains with single bonds allowing free rotation, resulting in high elasticity and deformability. Rigid polymers feature tightly packed, linear or cross-linked chains with double bonds or aromatic rings restricting rotational freedom, enhancing strength and thermal stability. The presence of bulky side groups and strong intermolecular forces in rigid polymers contrasts with the simpler, more mobile structures in flexible polymers, directly influencing their mechanical properties.

Applications of Flexible Polymers

Flexible polymers, characterized by their elasticity and low glass transition temperatures, are widely used in applications such as wearable electronics, medical devices, and flexible packaging. Their ability to deform without breaking makes them ideal for producing soft robotics components and stretchable sensors. Industries leverage flexible polymers like polyurethane and silicone for manufacturing products requiring durability combined with flexibility.

Uses of Rigid Polymers in Industry

Rigid polymers, known for their high mechanical strength and thermal stability, are extensively used in industries such as automotive, aerospace, and construction for manufacturing components that require durability and resistance to deformation. Applications include rigid PVC pipes, polycarbonate panels for bullet-resistant glass, and polyamide gears that maintain dimensional stability under stress. Their ability to withstand harsh environmental conditions makes them ideal for precision parts, protective casings, and structural supports.

Mechanical Performance Analysis

Flexible polymers exhibit superior elongation at break and impact resistance compared to rigid polymers, making them ideal for applications requiring high deformation and energy absorption. Rigid polymers demonstrate higher tensile strength and modulus, providing excellent dimensional stability and load-bearing capabilities essential for structural components. Mechanical performance analysis reveals that the choice between flexible and rigid polymers depends on balancing toughness with stiffness to meet specific engineering requirements.

Durability and Lifespan Considerations

Flexible polymers exhibit superior durability in applications requiring repeated bending and stretching due to their high elongation at break and resistance to fatigue, extending their operational lifespan in dynamic environments. Rigid polymers, characterized by their high tensile strength and resistance to deformation, offer long-term stability and lifespan in static or load-bearing applications but may suffer from brittleness under impact stress. Selecting between flexible and rigid polymers hinges on balancing durability needs with environmental stresses and mechanical demands to optimize lifespan and performance.

Processing and Manufacturing Methods

Flexible polymers such as polyethylene and silicone elastomers are processed primarily through methods like extrusion, injection molding, and blow molding due to their ability to withstand deformation without cracking. Rigid polymers like polycarbonate and polystyrene often require more precise processing techniques such as thermoforming, compression molding, and injection molding under controlled temperature and pressure to maintain structural integrity. The selection of manufacturing methods is heavily influenced by the polymer's mechanical properties, thermal stability, and end-use requirements.

Cost and Economic Factors

Flexible polymers generally offer lower production and processing costs due to their simpler molecular structure and reduced energy requirements during manufacturing. Rigid polymers often involve higher expenses linked to specialized processing techniques and enhanced material properties that justify their premium pricing in applications demanding durability. Economic factors favor flexible polymers in mass-market products where cost efficiency is critical, while rigid polymers command value in niche industries requiring structural integrity.

Future Trends in Polymer Material Innovation

Flexible polymers, characterized by their network of pliable molecular chains, continue to dominate developments in wearable electronics and soft robotics due to their adaptability and resilience. Rigid polymers, with their structured aromatic rings and high glass transition temperatures, are being innovated for advanced aerospace components requiring exceptional thermal stability and mechanical strength. Emerging polymer blends and nanocomposites that integrate flexible and rigid properties aim to revolutionize material performance, enabling smart, multifunctional polymers with applications spanning biomedicine to sustainable packaging.

Flexible Polymer vs Rigid Polymer Infographic

materialdif.com

materialdif.com