Melt Flow Index (MFI) inversely correlates with molecular weight in polymers, as higher molecular weight results in increased chain entanglement, reducing flowability under heat. Lower MFI values indicate polymers with longer chains and higher molecular weights, making them suitable for applications requiring greater strength and durability. Understanding the MFI-to-molecular-weight relationship is crucial for optimizing polymer processing conditions and end-use properties.

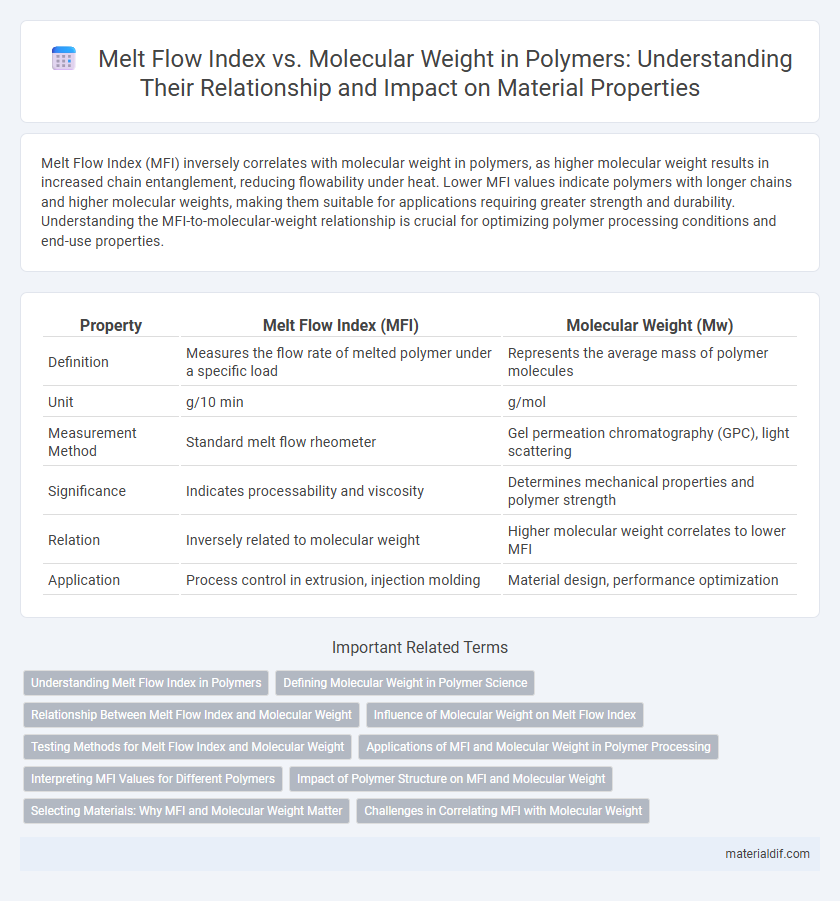

Table of Comparison

| Property | Melt Flow Index (MFI) | Molecular Weight (Mw) |

|---|---|---|

| Definition | Measures the flow rate of melted polymer under a specific load | Represents the average mass of polymer molecules |

| Unit | g/10 min | g/mol |

| Measurement Method | Standard melt flow rheometer | Gel permeation chromatography (GPC), light scattering |

| Significance | Indicates processability and viscosity | Determines mechanical properties and polymer strength |

| Relation | Inversely related to molecular weight | Higher molecular weight correlates to lower MFI |

| Application | Process control in extrusion, injection molding | Material design, performance optimization |

Understanding Melt Flow Index in Polymers

Melt Flow Index (MFI) measures the ease of flow of a polymer melt under specific conditions, directly correlating with the polymer's molecular weight and chain entanglement. Higher molecular weight polymers exhibit lower MFI values due to increased viscosity and longer polymer chains that restrict flow. Understanding the relationship between MFI and molecular weight is essential for predicting polymer processing behavior and optimizing manufacturing parameters.

Defining Molecular Weight in Polymer Science

Molecular weight in polymer science refers to the average mass of polymer molecules, typically expressed as number-average (Mn) or weight-average (Mw) molecular weight, which directly impacts polymer properties such as viscosity and mechanical strength. The Melt Flow Index (MFI) inversely correlates with molecular weight, where higher molecular weight polymers exhibit lower MFI due to increased chain entanglement and resistance to flow under heat. Understanding molecular weight distribution is crucial for optimizing polymer processing and performance characteristics in applications ranging from packaging to automotive parts.

Relationship Between Melt Flow Index and Molecular Weight

The Melt Flow Index (MFI) inversely correlates with the molecular weight of a polymer, meaning higher molecular weights result in lower MFI values due to increased chain entanglements. Molecular weight directly influences polymer viscosity; as molecular weight rises, molecular chain length and entanglement density increase, hindering flow under heat and pressure conditions. Therefore, measuring MFI provides critical insight into the polymer's molecular weight distribution and processability characteristics.

Influence of Molecular Weight on Melt Flow Index

Molecular weight significantly influences the Melt Flow Index (MFI) of polymers, where higher molecular weights typically result in lower MFI values due to increased chain entanglements that restrict polymer flow. Polymers with low molecular weight exhibit higher MFI, indicating easier flow and better processability during extrusion or injection molding. Precise control of molecular weight distribution is crucial for tailoring polymer melt viscosity and optimizing manufacturing performance.

Testing Methods for Melt Flow Index and Molecular Weight

Melt Flow Index (MFI) testing uses a standardized procedure such as ASTM D1238, where polymer pellets are heated and extruded under a specific load to measure flow rate, reflecting polymer viscosity and processing behavior. Molecular weight is commonly determined by Gel Permeation Chromatography (GPC), which separates polymer chains based on size, providing detailed molecular weight distribution that correlates with mechanical properties. The relationship between MFI and molecular weight highlights the inverse correlation where higher molecular weight polymers typically exhibit lower MFI due to increased chain entanglements affecting melt flow.

Applications of MFI and Molecular Weight in Polymer Processing

Melt Flow Index (MFI) and Molecular Weight are critical parameters in polymer processing, directly influencing material behavior and application suitability. Polymers with high MFI exhibit lower viscosity, facilitating processes like injection molding and extrusion where ease of flow is essential. Molecular Weight determines mechanical properties and thermal stability, with higher molecular weights favored in applications requiring enhanced strength and durability such as automotive parts and high-performance films.

Interpreting MFI Values for Different Polymers

Melt Flow Index (MFI) measures the ease of flow of a polymer melt and inversely correlates with molecular weight, as higher molecular weight polymers exhibit lower MFI values due to increased chain entanglements. Interpreting MFI requires understanding that polymers like polyethylene with high molecular weight show low MFI, indicating higher viscosity and strength, while polymers with lower molecular weight have higher MFI, reflecting easier processing. Different polymer grades such as polypropylene and polystyrene must be assessed relative to their specific MFI ranges to optimize processing conditions and end-use properties.

Impact of Polymer Structure on MFI and Molecular Weight

Melt Flow Index (MFI) inversely correlates with molecular weight because higher molecular weight polymers have longer chains causing increased chain entanglement, which restricts flow under heat. Polymer branching and chain architecture significantly influence MFI; linear polymers exhibit lower MFI due to tighter chain packing, whereas branched or star-shaped polymers show higher MFI from reduced entanglement. The presence of copolymers and molecular weight distribution further modifies flow behavior, affecting processability and mechanical properties.

Selecting Materials: Why MFI and Molecular Weight Matter

Melt Flow Index (MFI) and molecular weight are critical parameters for selecting polymer materials because they directly influence processing behavior and final product properties. A higher MFI indicates lower molecular weight, resulting in easier flow during molding but potentially reduced mechanical strength and durability. Understanding the balance between MFI and molecular weight enables manufacturers to optimize polymer selection for specific applications, ensuring ideal performance and manufacturability.

Challenges in Correlating MFI with Molecular Weight

Correlating Melt Flow Index (MFI) with molecular weight presents challenges due to the non-linear relationship influenced by polymer branching, molecular weight distribution, and test conditions. MFI measures flow under specific shear and temperature, which does not directly quantify molecular weight but reflects viscous behavior affected by chain entanglements and polymer architecture. Variability in molecular weight averages, such as weight-average (Mw) and number-average (Mn), further complicates establishing a consistent correlation with MFI values.

Melt Flow Index vs Molecular Weight Infographic

materialdif.com

materialdif.com