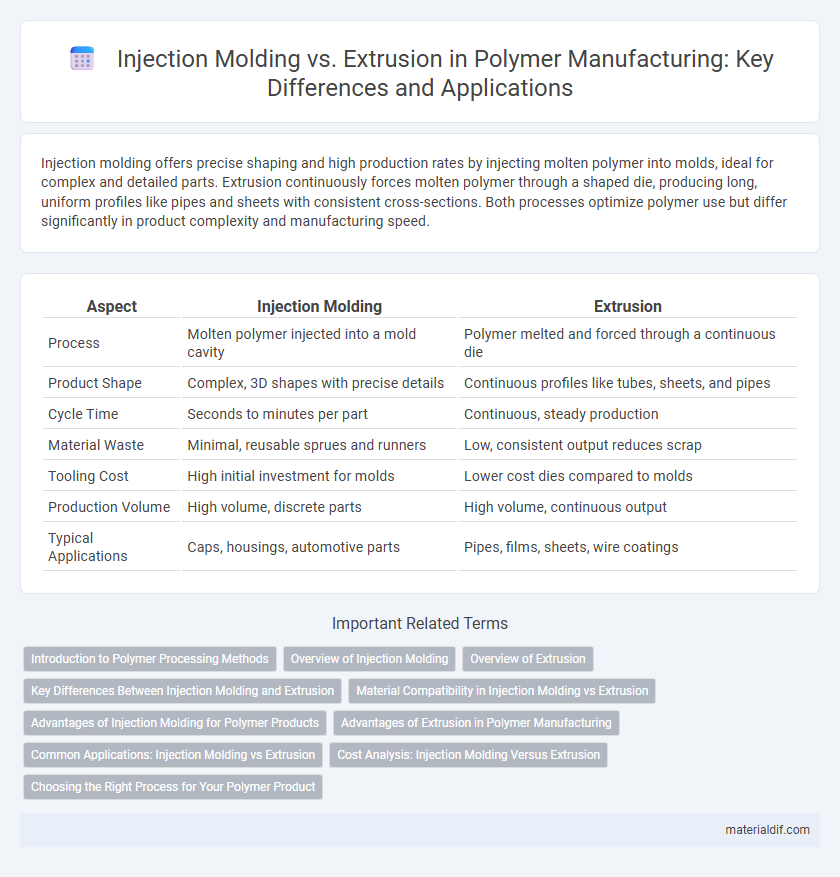

Injection molding offers precise shaping and high production rates by injecting molten polymer into molds, ideal for complex and detailed parts. Extrusion continuously forces molten polymer through a shaped die, producing long, uniform profiles like pipes and sheets with consistent cross-sections. Both processes optimize polymer use but differ significantly in product complexity and manufacturing speed.

Table of Comparison

| Aspect | Injection Molding | Extrusion |

|---|---|---|

| Process | Molten polymer injected into a mold cavity | Polymer melted and forced through a continuous die |

| Product Shape | Complex, 3D shapes with precise details | Continuous profiles like tubes, sheets, and pipes |

| Cycle Time | Seconds to minutes per part | Continuous, steady production |

| Material Waste | Minimal, reusable sprues and runners | Low, consistent output reduces scrap |

| Tooling Cost | High initial investment for molds | Lower cost dies compared to molds |

| Production Volume | High volume, discrete parts | High volume, continuous output |

| Typical Applications | Caps, housings, automotive parts | Pipes, films, sheets, wire coatings |

Introduction to Polymer Processing Methods

Injection molding and extrusion are two fundamental polymer processing methods used to shape thermoplastic and thermosetting materials into desired forms. Injection molding involves melting polymer pellets and injecting the molten plastic into a mold cavity under high pressure, enabling the production of complex, high-precision parts with rapid cycle times. Extrusion forces molten polymer through a shaped die to create continuous profiles such as pipes, sheets, or films, offering efficient production for uniform cross-sectional products.

Overview of Injection Molding

Injection molding is a manufacturing process where molten polymer is injected into a mold cavity to produce precise, complex shapes with high repeatability. This technique is ideal for mass production of detailed parts such as automotive components, medical devices, and consumer goods due to its ability to achieve tight tolerances and excellent surface finishes. Injection molding supports a wide range of thermoplastics and thermosetting polymers, offering versatility in material selection for various applications.

Overview of Extrusion

Extrusion is a continuous polymer processing technique where molten material is forced through a shaped die to create long, uniform profiles such as pipes, sheets, or films. This method offers high production rates and excellent control over cross-sectional dimensions, making it ideal for manufacturing consistent, intricate shapes. Extrusion's versatility accommodates a wide range of thermoplastics, including polyethylene, polypropylene, and PVC, supporting diverse industrial applications.

Key Differences Between Injection Molding and Extrusion

Injection molding produces complex, precise shapes by injecting molten polymer into molds, ideal for high-volume, detailed parts such as automotive components and medical devices. Extrusion continuously shapes polymers by forcing them through a die, creating uniform profiles like pipes, sheets, and films used in construction and packaging. Injection molding enables intricate geometries with tight tolerances, while extrusion offers efficient production of long, consistent cross-sections.

Material Compatibility in Injection Molding vs Extrusion

Injection molding accommodates a wide range of thermoplastic polymers such as ABS, polycarbonate, and polypropylene due to its ability to precisely control temperature and pressure, enabling complex geometries with tight tolerances. Extrusion primarily suits polymers like polyethylene, PVC, and nylon, which can be continuously melted and shaped into consistent profiles without the need for mold cavities. Material compatibility in injection molding emphasizes controlled thermal processing and molding intricacy, whereas extrusion prioritizes polymer melt flow characteristics essential for uniform continuous production.

Advantages of Injection Molding for Polymer Products

Injection molding offers superior precision and design flexibility for producing complex polymer products with intricate geometries and tight tolerances. This process enables high-volume manufacturing with consistent quality and minimal material waste, reducing overall production costs. Enhanced surface finish and the ability to incorporate multiple materials or colors in a single mold cycle make injection molding ideal for advanced polymer applications.

Advantages of Extrusion in Polymer Manufacturing

Extrusion in polymer manufacturing offers continuous production of complex cross-sectional profiles with highly consistent quality and minimal material waste. The process provides greater flexibility in producing long lengths of uniform shapes such as pipes, sheets, and films, making it ideal for high-volume applications. Extrusion also enables precise control over thickness and surface finish, enhancing product performance and reducing post-processing requirements.

Common Applications: Injection Molding vs Extrusion

Injection molding is commonly used for manufacturing complex, high-precision parts such as automotive components, medical devices, and consumer electronics enclosures, where detailed shapes and tight tolerances are essential. Extrusion is primarily applied in producing continuous profiles like pipes, tubing, sheets, and films for construction, packaging, and electrical insulation. Both processes utilize thermoplastic polymers, but injection molding excels in customized part production while extrusion suits large-scale, uniform cross-section products.

Cost Analysis: Injection Molding Versus Extrusion

Injection molding involves higher initial costs due to expensive molds and setup, but it offers lower per-unit expenses for large production runs compared to extrusion. Extrusion has a lower startup cost and is more cost-effective for continuous profiles and simpler shapes, especially in smaller batch sizes. Economies of scale heavily favor injection molding for mass production, while extrusion remains preferable for flexible, lower-volume manufacturing.

Choosing the Right Process for Your Polymer Product

Injection molding offers high precision and complex geometries, making it ideal for producing detailed polymer components with tight tolerances. Extrusion is more suitable for creating continuous shapes like pipes, sheets, and profiles, providing cost-effective production for long runs. Selecting the right process depends on product design, volume requirements, and material properties to ensure optimal performance and manufacturing efficiency.

Injection Molding vs Extrusion Infographic

materialdif.com

materialdif.com