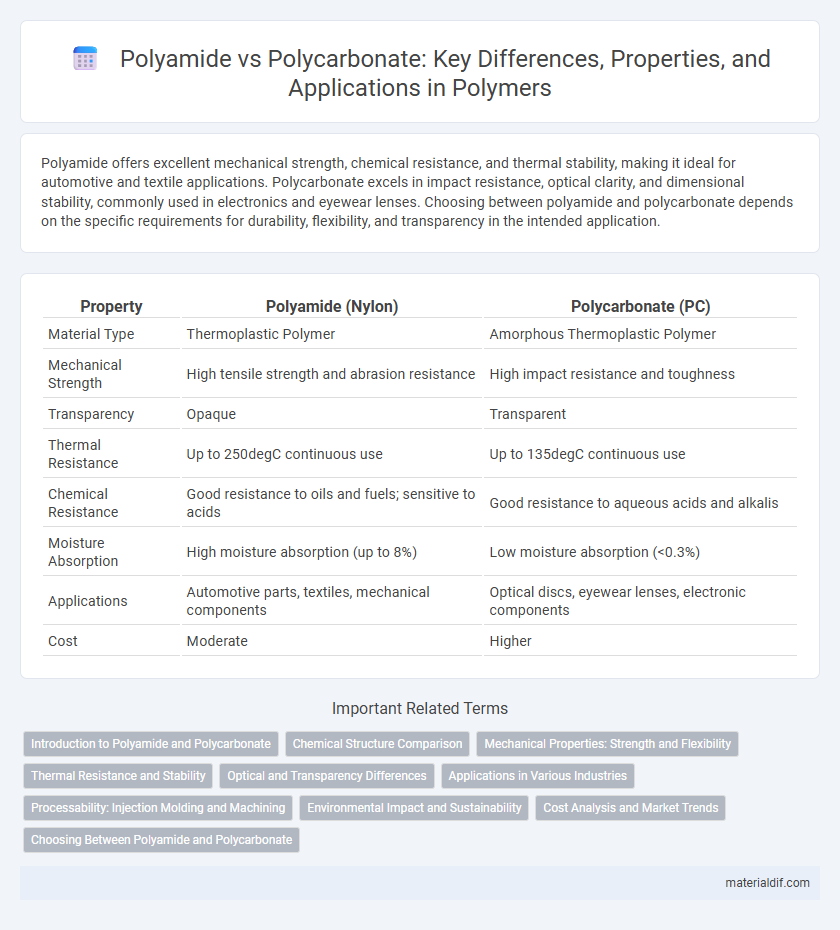

Polyamide offers excellent mechanical strength, chemical resistance, and thermal stability, making it ideal for automotive and textile applications. Polycarbonate excels in impact resistance, optical clarity, and dimensional stability, commonly used in electronics and eyewear lenses. Choosing between polyamide and polycarbonate depends on the specific requirements for durability, flexibility, and transparency in the intended application.

Table of Comparison

| Property | Polyamide (Nylon) | Polycarbonate (PC) |

|---|---|---|

| Material Type | Thermoplastic Polymer | Amorphous Thermoplastic Polymer |

| Mechanical Strength | High tensile strength and abrasion resistance | High impact resistance and toughness |

| Transparency | Opaque | Transparent |

| Thermal Resistance | Up to 250degC continuous use | Up to 135degC continuous use |

| Chemical Resistance | Good resistance to oils and fuels; sensitive to acids | Good resistance to aqueous acids and alkalis |

| Moisture Absorption | High moisture absorption (up to 8%) | Low moisture absorption (<0.3%) |

| Applications | Automotive parts, textiles, mechanical components | Optical discs, eyewear lenses, electronic components |

| Cost | Moderate | Higher |

Introduction to Polyamide and Polycarbonate

Polyamide, commonly known as nylon, is a versatile polymer characterized by strong hydrogen bonding, high tensile strength, and excellent chemical resistance, making it ideal for textiles and engineering applications. Polycarbonate is an amorphous thermoplastic known for its remarkable impact resistance, optical transparency, and high heat resistance, frequently used in eyewear lenses, electronic components, and automotive parts. Both polymers differ significantly in mechanical properties and applications, with polyamide excelling in durability and polycarbonate in clarity and toughness.

Chemical Structure Comparison

Polyamide features repeating amide linkages (-CONH-) in its backbone, providing strong hydrogen bonding and high thermal resistance. Polycarbonate contains carbonate groups (-O-(C=O)-O-) between aromatic rings, offering excellent impact resistance and transparency. The differing molecular structures result in polyamide's superior mechanical strength and polycarbonate's enhanced optical clarity and toughness.

Mechanical Properties: Strength and Flexibility

Polyamide exhibits high tensile strength and excellent flexibility, making it ideal for applications requiring impact resistance and durability. Polycarbonate offers superior stiffness and impact resistance but is less flexible than polyamide, which limits its deformation capabilities under stress. The choice between polyamide and polycarbonate depends on the required balance of mechanical strength and flexibility for specific engineering applications.

Thermal Resistance and Stability

Polyamide exhibits high thermal resistance with a melting point typically around 215-265degC, making it suitable for applications requiring moderate heat endurance. Polycarbonate offers superior thermal stability with a glass transition temperature near 147degC and maintains dimensional stability under prolonged heat exposure. The enhanced thermal performance of polycarbonate supports its use in demanding environments where sustained mechanical properties at elevated temperatures are critical.

Optical and Transparency Differences

Polyamide exhibits lower optical clarity compared to polycarbonate, which offers superior transparency and light transmission rates above 90%. Polycarbonate maintains excellent impact resistance while delivering nearly glass-like transparency, making it ideal for optical lenses and protective shields. In contrast, polyamide tends to have a more opaque appearance and can exhibit a slightly yellowish tint, limiting its use in applications requiring high visual clarity.

Applications in Various Industries

Polyamide exhibits outstanding mechanical strength and chemical resistance, making it ideal for automotive parts, textiles, and electrical components. Polycarbonate offers exceptional impact resistance and optical clarity, frequently used in eyewear lenses, medical devices, and electronic housings. Both polymers serve crucial roles in aerospace, manufacturing, and consumer goods due to their specific performance attributes and durability.

Processability: Injection Molding and Machining

Polyamide offers excellent processability in injection molding due to its low melt viscosity, enabling precise detail replication and fast cycle times, while polycarbonate requires higher processing temperatures and careful thermal control to prevent degradation. In machining, polyamide exhibits good machinability with reduced tool wear, whereas polycarbonate's toughness demands specialized tooling and slower feed rates to avoid surface defects. Both polymers demonstrate versatile processing capabilities but necessitate tailored parameters to optimize performance in injection molding and machining applications.

Environmental Impact and Sustainability

Polyamide and polycarbonate differ significantly in environmental impact and sustainability profiles, with polyamide generally deriving from petrochemical sources and exhibiting lower recyclability. Polycarbonate offers higher durability and potential for reuse, but its production involves bisphenol A, raising concerns about toxicity and environmental persistence. Advances in bio-based polyamides and improved recycling technologies for polycarbonate are key to enhancing sustainability in applications ranging from automotive components to consumer electronics.

Cost Analysis and Market Trends

Polyamide typically offers a lower raw material cost compared to polycarbonate, making it a preferred choice for budget-sensitive applications in automotive and textile industries. Market trends indicate rising demand for polycarbonate due to its superior impact resistance and optical clarity, driving higher prices but expanding usage in electronics and automotive glazing. The cost analysis also highlights polyamide's advantage in production efficiency and recyclability, maintaining competitive pricing despite polycarbonate's technological benefits.

Choosing Between Polyamide and Polycarbonate

Polyamide, known for its excellent mechanical strength, abrasion resistance, and chemical stability, is ideal for applications requiring durability and flexibility, such as automotive parts and textiles. Polycarbonate excels in impact resistance, optical clarity, and heat resistance, making it suitable for eyewear lenses, protective gear, and electronic components. When choosing between polyamide and polycarbonate, consider factors like mechanical stress, environmental exposure, transparency needs, and thermal performance to select the appropriate polymer for specific industrial or consumer applications.

Polyamide vs Polycarbonate Infographic

materialdif.com

materialdif.com