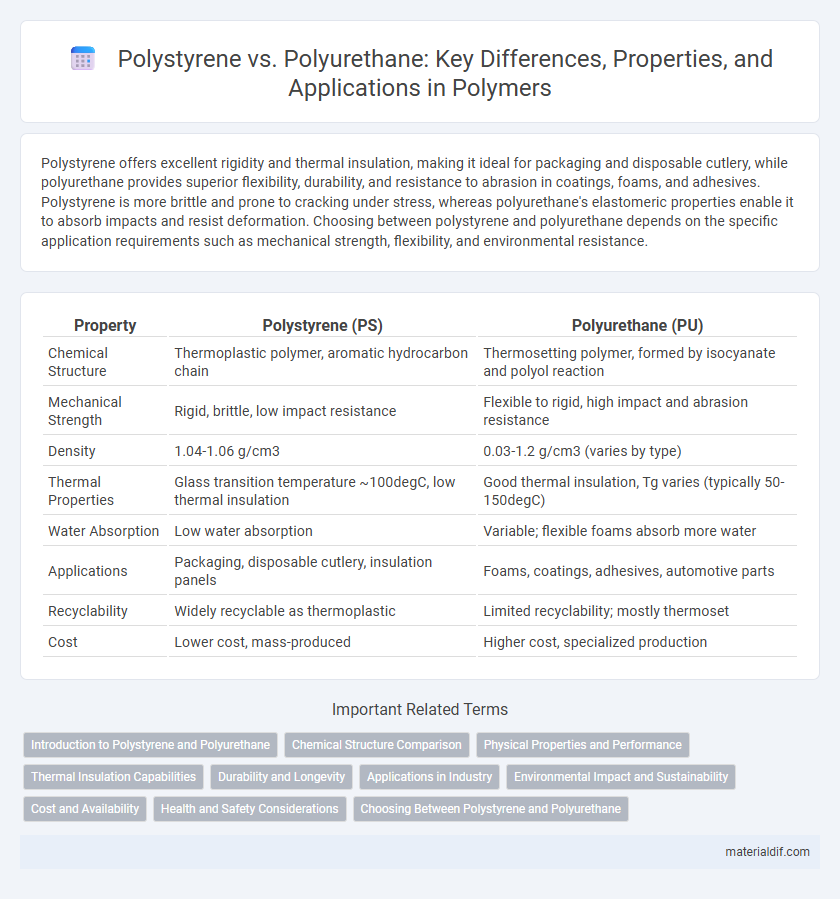

Polystyrene offers excellent rigidity and thermal insulation, making it ideal for packaging and disposable cutlery, while polyurethane provides superior flexibility, durability, and resistance to abrasion in coatings, foams, and adhesives. Polystyrene is more brittle and prone to cracking under stress, whereas polyurethane's elastomeric properties enable it to absorb impacts and resist deformation. Choosing between polystyrene and polyurethane depends on the specific application requirements such as mechanical strength, flexibility, and environmental resistance.

Table of Comparison

| Property | Polystyrene (PS) | Polyurethane (PU) |

|---|---|---|

| Chemical Structure | Thermoplastic polymer, aromatic hydrocarbon chain | Thermosetting polymer, formed by isocyanate and polyol reaction |

| Mechanical Strength | Rigid, brittle, low impact resistance | Flexible to rigid, high impact and abrasion resistance |

| Density | 1.04-1.06 g/cm3 | 0.03-1.2 g/cm3 (varies by type) |

| Thermal Properties | Glass transition temperature ~100degC, low thermal insulation | Good thermal insulation, Tg varies (typically 50-150degC) |

| Water Absorption | Low water absorption | Variable; flexible foams absorb more water |

| Applications | Packaging, disposable cutlery, insulation panels | Foams, coatings, adhesives, automotive parts |

| Recyclability | Widely recyclable as thermoplastic | Limited recyclability; mostly thermoset |

| Cost | Lower cost, mass-produced | Higher cost, specialized production |

Introduction to Polystyrene and Polyurethane

Polystyrene is a versatile thermoplastic polymer known for its rigidity, clarity, and ease of molding, widely used in packaging, insulation, and disposable containers. Polyurethane, a polymer composed of organic units joined by carbamate (urethane) links, exhibits remarkable flexibility, durability, and resistance to abrasion, commonly applied in foams, coatings, adhesives, and elastomers. Both polymers serve distinct industrial purposes, with polystyrene excelling in structural applications and polyurethane favored for cushioning and protective layers.

Chemical Structure Comparison

Polystyrene features a linear hydrocarbon backbone with phenyl groups attached to every other carbon atom, resulting in a rigid and glassy polymer structure. Polyurethane consists of repeating units formed by the reaction between diisocyanates and polyols, creating urethane linkages (carbamate groups) that provide flexibility and durability. The aromatic rings in polystyrene confer rigidity, while the segmented structure and urethane bonds in polyurethane enable elastomeric properties and chemical resistance.

Physical Properties and Performance

Polystyrene exhibits high rigidity and excellent dimensional stability but is brittle and has low impact resistance, making it suitable for lightweight, rigid applications. Polyurethane offers superior flexibility, high abrasion resistance, and excellent impact absorption, which enhances its durability in dynamic and cushioning environments. The thermal insulation properties of polystyrene contrast with the elastomeric nature of polyurethane, influencing their performance in insulation versus cushioning applications.

Thermal Insulation Capabilities

Polystyrene offers excellent thermal insulation due to its closed-cell structure, providing high resistance to heat transfer and commonly used in insulation panels and packaging. Polyurethane foam exhibits superior thermal performance with a lower thermal conductivity, making it ideal for spray foam insulation and applications requiring airtight sealing. The choice between polystyrene and polyurethane depends on the required R-value, moisture resistance, and installation method for optimal energy efficiency.

Durability and Longevity

Polystyrene offers moderate durability with resistance to impact and moisture, making it suitable for insulation and packaging applications but prone to brittleness over time. Polyurethane exhibits superior durability and longevity due to its flexibility, resistance to abrasion, and excellent performance under varying environmental conditions. This enhanced resilience allows polyurethane to maintain structural integrity and functionality for extended periods in automotive, foam, and coating industries.

Applications in Industry

Polystyrene is widely used in packaging, insulation, and disposable consumer products due to its rigidity and low cost, making it ideal for protecting goods and thermal insulation in construction. Polyurethane is favored in automotive, furniture, and footwear industries for its superior flexibility, durability, and cushioning properties, enhancing comfort and wear resistance. Industrial applications exploit polystyrene's structural stability and polyurethane's versatile elastomeric and foam forms to meet specific performance demands.

Environmental Impact and Sustainability

Polystyrene, derived from fossil fuels, is non-biodegradable and poses significant environmental hazards due to persistent plastic waste in landfills and oceans. Polyurethane, while also petrochemical-based, offers greater potential for recycling and can incorporate bio-based polyols, enhancing its sustainability profile. Advances in polyurethane formulations aim to reduce carbon footprint and improve biodegradability, positioning it as a more environmentally responsible choice compared to traditional polystyrene.

Cost and Availability

Polystyrene is generally more cost-effective and widely available due to its extensive use in packaging, insulation, and disposable products, making it a preferred choice for budget-conscious applications. Polyurethane, while often more expensive, offers superior flexibility and durability, which can justify its higher price in specialized industries such as automotive and furniture manufacturing. The global production scale of polystyrene significantly exceeds that of polyurethane, contributing to its broader market availability.

Health and Safety Considerations

Polystyrene poses health risks due to styrene exposure, which can cause respiratory issues and skin irritation, while its combustion releases toxic fumes. Polyurethane, commonly used as foam insulation, may emit isocyanates during production and curing, substances linked to asthma and allergic reactions. Proper ventilation and protective equipment are crucial when handling both polymers to minimize inhalation hazards and prevent long-term health effects.

Choosing Between Polystyrene and Polyurethane

Choosing between polystyrene and polyurethane depends on the application's insulation needs, durability, and cost considerations. Polystyrene offers excellent thermal insulation with rigidity and affordability, making it ideal for lightweight, structural uses. Polyurethane provides superior thermal resistance and flexibility, suited for applications requiring enhanced durability and impact resistance.

Polystyrene vs Polyurethane Infographic

materialdif.com

materialdif.com