Polystyrene offers excellent rigidity and clarity, making it ideal for disposable cutlery and packaging, while ABS provides superior impact resistance and toughness, suitable for automotive parts and electronic housings. Polystyrene is more brittle and prone to cracking under stress, whereas ABS can withstand higher mechanical loads and heat. Choosing between polystyrene and ABS depends on the application requirements for durability, flexibility, and cost-effectiveness.

Table of Comparison

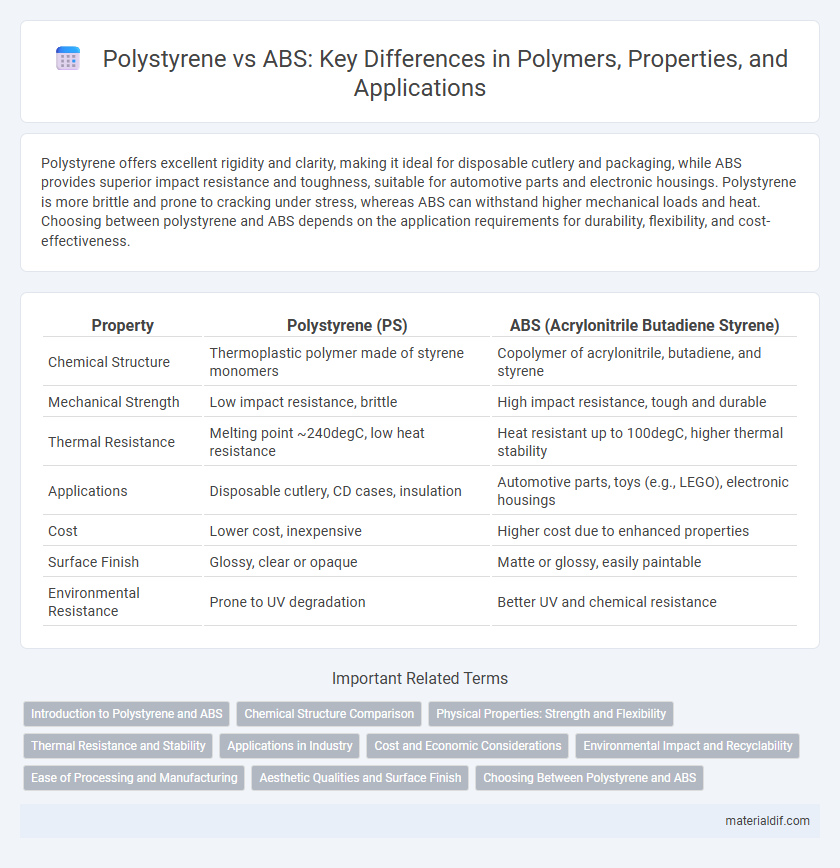

| Property | Polystyrene (PS) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

| Chemical Structure | Thermoplastic polymer made of styrene monomers | Copolymer of acrylonitrile, butadiene, and styrene |

| Mechanical Strength | Low impact resistance, brittle | High impact resistance, tough and durable |

| Thermal Resistance | Melting point ~240degC, low heat resistance | Heat resistant up to 100degC, higher thermal stability |

| Applications | Disposable cutlery, CD cases, insulation | Automotive parts, toys (e.g., LEGO), electronic housings |

| Cost | Lower cost, inexpensive | Higher cost due to enhanced properties |

| Surface Finish | Glossy, clear or opaque | Matte or glossy, easily paintable |

| Environmental Resistance | Prone to UV degradation | Better UV and chemical resistance |

Introduction to Polystyrene and ABS

Polystyrene is a versatile thermoplastic polymer known for its rigidity, clarity, and excellent insulating properties, commonly used in packaging, disposable cutlery, and insulation materials. Acrylonitrile Butadiene Styrene (ABS) is a robust thermoplastic copolymer characterized by high impact resistance, toughness, and ease of machining, widely utilized in automotive components, electronic housings, and consumer products. Both polymers offer distinct advantages in chemical resistance and mechanical properties, making them suitable for diverse industrial and commercial applications.

Chemical Structure Comparison

Polystyrene consists of a linear polymer chain with repeating styrene units characterized by a phenyl group attached to a vinyl backbone, providing rigidity and clarity. ABS (Acrylonitrile Butadiene Styrene) is a copolymer composed of acrylonitrile, butadiene, and styrene units, where the butadiene segments impart toughness and impact resistance due to their rubbery nature. The chemical structure of ABS combines the stiffness of styrene and acrylonitrile with the elasticity of butadiene, making it more versatile and durable compared to the more brittle and transparent polystyrene.

Physical Properties: Strength and Flexibility

Polystyrene offers high rigidity and excellent strength but lacks flexibility, making it prone to brittleness under stress. ABS combines good strength with superior impact resistance and flexibility, allowing it to absorb shocks without cracking. The choice between polystyrene and ABS depends on application requirements for durability and mechanical performance.

Thermal Resistance and Stability

Polystyrene exhibits lower thermal resistance with a heat deflection temperature around 95degC, making it less stable under elevated heat conditions compared to ABS. ABS (Acrylonitrile Butadiene Styrene) offers superior thermal stability, withstanding temperatures up to 105-110degC due to its rubbery butadiene component that enhances heat resistance. The choice between polystyrene and ABS depends on application temperature requirements and the need for long-term thermal durability.

Applications in Industry

Polystyrene is widely used in packaging, disposable cutlery, and insulation due to its rigidity and clarity, making it ideal for products requiring transparency and lightweight properties. ABS (Acrylonitrile Butadiene Styrene) finds extensive application in automotive components, electronic housings, and consumer goods because of its superior impact resistance, toughness, and thermal stability. Industries prefer ABS for durable mechanical parts, while polystyrene dominates in cost-effective, rigid, and easily moldable packaging solutions.

Cost and Economic Considerations

Polystyrene is generally more cost-effective than ABS due to its lower raw material and processing expenses, making it suitable for applications requiring economical mass production. ABS offers superior impact resistance and toughness but comes at a higher price, influencing its use in more durable and premium products. Evaluating the balance between performance needs and budget constraints is critical when choosing between polystyrene and ABS in manufacturing projects.

Environmental Impact and Recyclability

Polystyrene (PS) is widely used for packaging but poses significant environmental challenges due to its non-biodegradability and difficulty in recycling, often resulting in persistent plastic waste. ABS (Acrylonitrile Butadiene Styrene) offers better mechanical properties and can be recycled more efficiently through mechanical and chemical processes, although its composite nature complicates full-scale recycling. Both polymers contribute to environmental pollution, but ABS's higher recyclability and potential for reprocessing give it a comparative advantage in reducing long-term ecological impact.

Ease of Processing and Manufacturing

Polystyrene offers ease of processing due to its low melt viscosity and straightforward molding characteristics, making it ideal for high-speed injection molding applications. ABS, while slightly more complex to process than polystyrene, provides superior impact resistance and dimensional stability, requiring precise temperature control during extrusion and injection molding. Manufacturers often choose polystyrene for cost-effective, fast production, whereas ABS is preferred for durable, high-performance components despite longer processing times.

Aesthetic Qualities and Surface Finish

Polystyrene offers a glossy, smooth surface finish with excellent ability to accept vibrant colors and detailed textures, making it ideal for decorative applications. ABS exhibits superior impact resistance and can achieve a matte or textured finish that enhances durability and hides surface imperfections better than polystyrene. The choice between Polystyrene and ABS depends on whether the priority is a high-gloss, crisp appearance or a robust, textured surface with enhanced toughness.

Choosing Between Polystyrene and ABS

Choosing between polystyrene and ABS depends on the application's strength and durability requirements. Polystyrene offers excellent clarity and rigidity, ideal for lightweight, low-impact uses, while ABS provides superior impact resistance and toughness, suitable for more demanding mechanical parts. Cost considerations also play a role, as polystyrene is generally more affordable but less resistant to heat and chemicals compared to ABS.

Polystyrene vs ABS Infographic

materialdif.com

materialdif.com