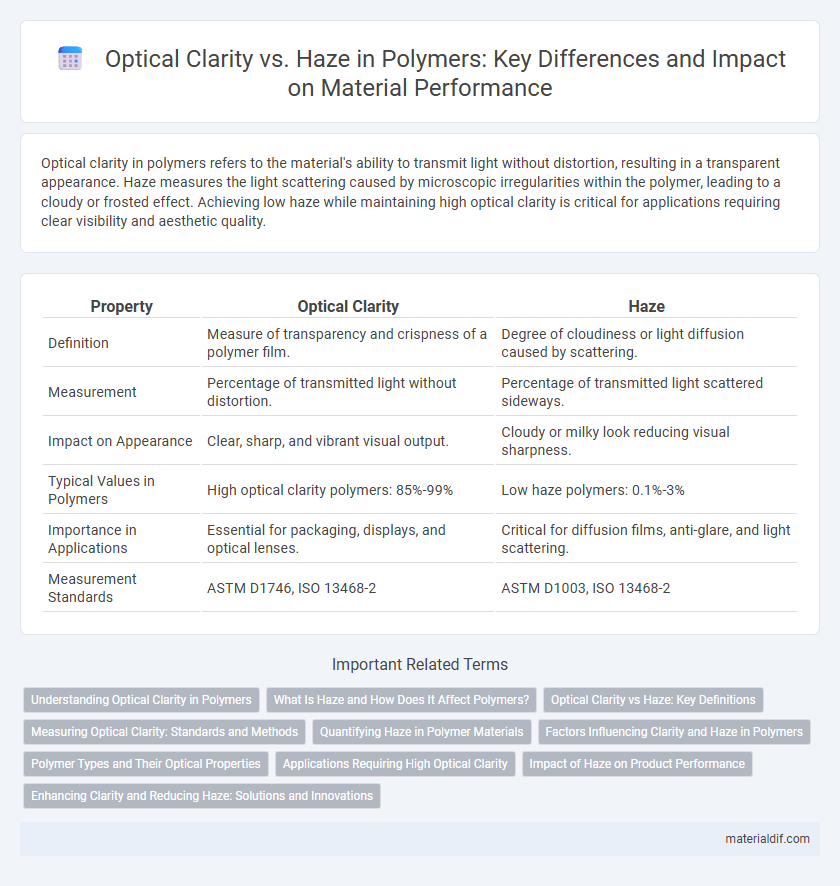

Optical clarity in polymers refers to the material's ability to transmit light without distortion, resulting in a transparent appearance. Haze measures the light scattering caused by microscopic irregularities within the polymer, leading to a cloudy or frosted effect. Achieving low haze while maintaining high optical clarity is critical for applications requiring clear visibility and aesthetic quality.

Table of Comparison

| Property | Optical Clarity | Haze |

|---|---|---|

| Definition | Measure of transparency and crispness of a polymer film. | Degree of cloudiness or light diffusion caused by scattering. |

| Measurement | Percentage of transmitted light without distortion. | Percentage of transmitted light scattered sideways. |

| Impact on Appearance | Clear, sharp, and vibrant visual output. | Cloudy or milky look reducing visual sharpness. |

| Typical Values in Polymers | High optical clarity polymers: 85%-99% | Low haze polymers: 0.1%-3% |

| Importance in Applications | Essential for packaging, displays, and optical lenses. | Critical for diffusion films, anti-glare, and light scattering. |

| Measurement Standards | ASTM D1746, ISO 13468-2 | ASTM D1003, ISO 13468-2 |

Understanding Optical Clarity in Polymers

Optical clarity in polymers refers to the material's ability to transmit light without significant scattering, resulting in a clear and transparent appearance. Haze is a critical factor that measures the degree of light diffusion caused by microscopic surface irregularities or internal structures within the polymer matrix. Understanding the interplay between optical clarity and haze is essential for applications requiring high transparency, such as lenses, packaging films, and display screens.

What Is Haze and How Does It Affect Polymers?

Haze in polymers refers to the cloudiness or reduction in transparency caused by light scattering within the material, often resulting from surface roughness, impurities, or internal stress. This optical phenomenon decreases the optical clarity of polymers by diffusing transmitted light, which affects applications requiring high transparency such as lenses, packaging, and displays. Controlling haze is critical in polymer manufacturing processes to maintain clarity, enhance aesthetic appeal, and ensure functional performance in optical components.

Optical Clarity vs Haze: Key Definitions

Optical clarity in polymers refers to the material's ability to transmit light with minimal distortion, resulting in a clear and transparent appearance. Haze measures the scattering of transmitted light, causing a milky or foggy effect that reduces visibility through the polymer. High optical clarity combined with low haze is crucial for applications requiring clear visibility, such as packaging films and optical lenses.

Measuring Optical Clarity: Standards and Methods

Measuring optical clarity in polymers involves assessing light transmission and haze percentages using standardized methods such as ASTM D1003 and ISO 13468. These standards quantify optical clarity by determining total transmittance and haze levels to evaluate the polymer's visual quality and performance. Precise haze measurement provides critical data for applications demanding high transparency, ensuring materials meet optical clarity requirements.

Quantifying Haze in Polymer Materials

Quantifying haze in polymer materials involves measuring the percentage of light scattered as it passes through the polymer, directly impacting optical clarity. Instruments like haze meters evaluate light diffusion, providing precise haze values critical for applications requiring high transparency. Accurate haze quantification guides material selection and processing to optimize optical performance in films, lenses, and transparent packaging.

Factors Influencing Clarity and Haze in Polymers

Optical clarity in polymers is influenced by factors such as polymer crystallinity, molecular weight distribution, and the presence of additives or fillers that scatter light. Haze increases when polymer chains form microcrystalline regions or when inclusions like bubbles and impurities disrupt uniform light transmission. Processing conditions like cooling rate and extrusion parameters also impact clarity and haze by altering polymer morphology and internal stress.

Polymer Types and Their Optical Properties

Polymer types such as polymethyl methacrylate (PMMA) and polycarbonate exhibit high optical clarity due to their low light scattering properties, making them ideal for applications requiring transparency. In contrast, polymers like polyethylene terephthalate (PET) and polypropylene often display higher haze levels, caused by microscopic surface irregularities or internal phase separation. Understanding the intrinsic molecular structure and processing conditions of these polymers is critical for tailoring their optical properties in lenses, displays, and packaging materials.

Applications Requiring High Optical Clarity

Applications requiring high optical clarity, such as medical devices, optical lenses, and display screens, demand polymers with minimal haze to ensure transparent, distortion-free visuals. Polymers like polymethyl methacrylate (PMMA) and cyclo-olefin polymers (COP) exhibit superior optical clarity due to their low refractive index variance and excellent light transmission properties. Controlling haze in these materials is critical for performance, as even slight light scattering can impair visibility and accuracy in precision applications.

Impact of Haze on Product Performance

Haze in polymers reduces optical clarity by scattering light, which diminishes visual transparency and affects product aesthetics. Increased haze negatively impacts applications requiring high transparency, such as packaging, displays, and optical lenses, leading to reduced consumer appeal and functionality. Controlling haze is essential for maintaining product performance, especially in sectors demanding accurate light transmission and clear visibility.

Enhancing Clarity and Reducing Haze: Solutions and Innovations

Enhancing optical clarity in polymers involves advanced material formulations and surface treatments that minimize light scattering and improve transparency. Innovations such as incorporating nano-fillers, optimizing polymer crystallinity, and applying anti-reflective coatings significantly reduce haze levels, resulting in clearer and more visually appealing products. Emerging technologies like UV stabilization and precision compounding techniques further contribute to maintaining clarity under diverse environmental conditions.

Optical Clarity vs Haze Infographic

materialdif.com

materialdif.com