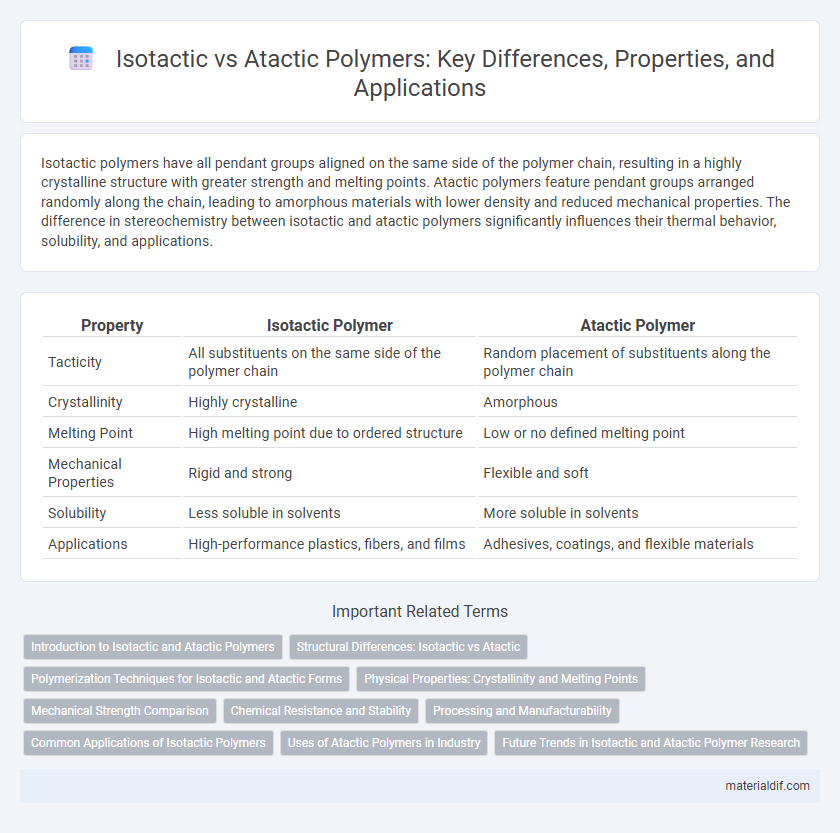

Isotactic polymers have all pendant groups aligned on the same side of the polymer chain, resulting in a highly crystalline structure with greater strength and melting points. Atactic polymers feature pendant groups arranged randomly along the chain, leading to amorphous materials with lower density and reduced mechanical properties. The difference in stereochemistry between isotactic and atactic polymers significantly influences their thermal behavior, solubility, and applications.

Table of Comparison

| Property | Isotactic Polymer | Atactic Polymer |

|---|---|---|

| Tacticity | All substituents on the same side of the polymer chain | Random placement of substituents along the polymer chain |

| Crystallinity | Highly crystalline | Amorphous |

| Melting Point | High melting point due to ordered structure | Low or no defined melting point |

| Mechanical Properties | Rigid and strong | Flexible and soft |

| Solubility | Less soluble in solvents | More soluble in solvents |

| Applications | High-performance plastics, fibers, and films | Adhesives, coatings, and flexible materials |

Introduction to Isotactic and Atactic Polymers

Isotactic polymers feature repeating units with identical stereochemical configurations aligned on the same side, resulting in higher crystallinity and enhanced mechanical properties. Atactic polymers exhibit a random arrangement of stereocenters along the polymer chain, leading to amorphous structures with lower density and reduced tensile strength. The stereoregularity in isotactic polymers primarily influences thermal resistance and chemical stability, distinguishing their applications from the more flexible and processable atactic variants.

Structural Differences: Isotactic vs Atactic

Isotactic polymers have all substituent groups arranged on the same side of the polymer backbone, leading to a regular, crystalline structure that enhances strength and melting point. Atactic polymers exhibit a random arrangement of substituent groups on both sides of the backbone, resulting in amorphous, flexible materials with lower crystallinity and melting temperatures. These structural differences directly impact the physical properties and applications of isotactic versus atactic polymers.

Polymerization Techniques for Isotactic and Atactic Forms

Isotactic polymers are synthesized using stereospecific polymerization techniques such as Ziegler-Natta and metallocene catalysts, which control the spatial arrangement of substituents along the polymer chain. Atactic polymers result from free radical or anionic polymerization methods, leading to random stereochemistry and amorphous polymer structures. The choice of catalyst and polymerization conditions directly influences the tacticity and resulting physical properties of the polymer.

Physical Properties: Crystallinity and Melting Points

Isotactic polymers exhibit high crystallinity due to their regular, repeating stereochemistry, resulting in well-ordered molecular packing and elevated melting points typically above 160degC for isotactic polypropylene. Atactic polymers possess irregular stereochemistry that hinders crystallization, resulting in amorphous structures with low or no melting points often below 60degC. The disparity in crystallinity directly influences mechanical strength, thermal resistance, and clarity, with isotactic forms providing superior toughness and heat resistance compared to their atactic counterparts.

Mechanical Strength Comparison

Isotactic polymers exhibit higher mechanical strength due to their ordered, crystalline structure that enhances tensile properties and impact resistance. Atactic polymers, with their irregular, amorphous arrangement, generally show lower mechanical strength and flexibility. The crystallinity in isotactic polymers directly correlates with improved durability and stiffness in various applications.

Chemical Resistance and Stability

Isotactic polymers exhibit higher chemical resistance and stability due to their regular, highly crystalline structure, which limits the penetration of chemicals and enhances thermal stability. Atactic polymers, with their irregular arrangement, show lower crystallinity, resulting in decreased chemical resistance and reduced mechanical stability under harsh conditions. These structural differences make isotactic polymers more suitable for applications requiring durability against solvents, acids, and bases.

Processing and Manufacturability

Isotactic polymers exhibit higher crystallinity, resulting in improved mechanical strength and thermal resistance, which facilitates easier processing through injection molding and extrusion techniques. Atactic polymers, characterized by their amorphous structure, offer greater flexibility and impact resistance but often require solvents or plasticizers to enhance flow during manufacturing. The choice between isotactic and atactic configurations directly influences polymer melt viscosity and cooling rates, critical parameters for optimizing manufacturability and final product performance.

Common Applications of Isotactic Polymers

Isotactic polymers, characterized by their uniform stereochemistry, exhibit high crystallinity and mechanical strength, making them ideal for applications in packaging films, automotive parts, and medical devices. Their enhanced thermal resistance and chemical stability allow use in durable consumer goods and electrical insulation materials. Common isotactic polymers include isotactic polypropylene, which is widely employed in injection molding and fiber production for textiles and ropes.

Uses of Atactic Polymers in Industry

Atactic polymers, characterized by their random side-group arrangement, are widely used in the production of adhesives, sealants, and coatings due to their amorphous and tacky nature. Their flexibility and inability to crystallize allow for excellent film-forming properties and enhanced adhesion performance in industries like construction and packaging. These polymers also serve as key components in impact modifiers and as plasticizers, improving the mechanical properties of various polymer blends.

Future Trends in Isotactic and Atactic Polymer Research

Future trends in isotactic polymer research emphasize enhancing stereoregularity to improve crystallinity, mechanical strength, and thermal stability for advanced applications in automotive and aerospace industries. Atactic polymers are increasingly explored for their amorphous properties, promoting innovations in flexible electronics, adhesives, and drug delivery systems. Emerging techniques in catalyst design and controlled polymerization promise tailored molecular architectures, enabling precise control over isotactic and atactic configurations to meet evolving material performance demands.

Isotactic vs Atactic Infographic

materialdif.com

materialdif.com