Polypropylene offers excellent chemical resistance and flexibility, making it ideal for packaging and automotive parts, while polycarbonate provides superior impact strength and transparency, commonly used in eyewear lenses and electronic components. Polypropylene is cost-effective and lightweight but has lower temperature resistance compared to the more durable and heat-resistant polycarbonate. Selecting between the two depends on the specific application requirements such as durability, thermal stability, and optical clarity.

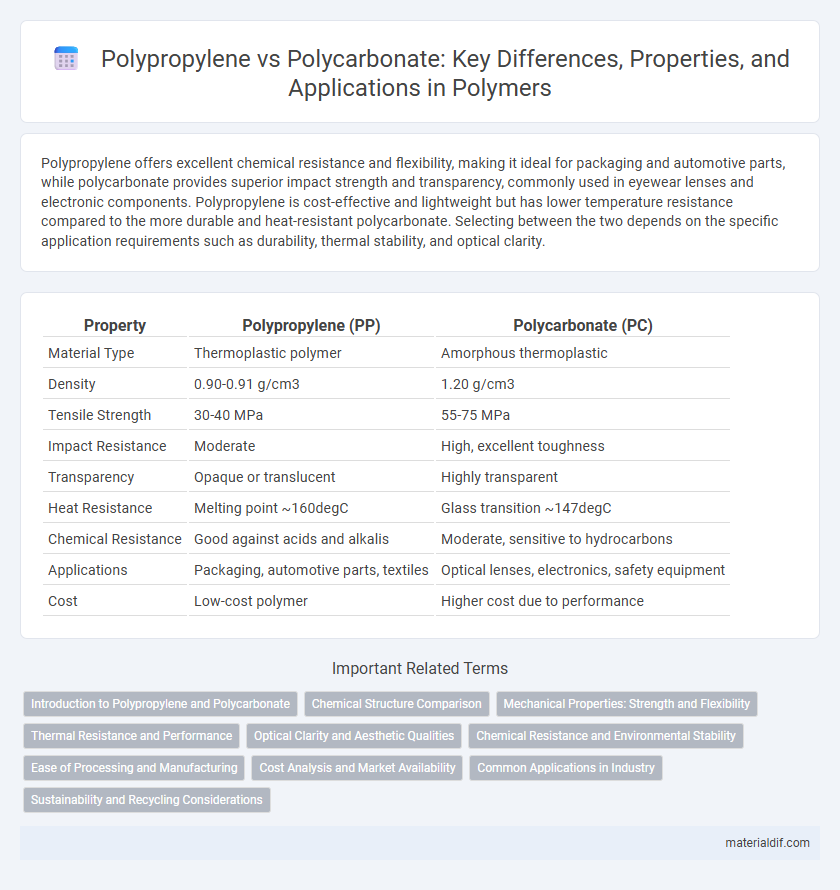

Table of Comparison

| Property | Polypropylene (PP) | Polycarbonate (PC) |

|---|---|---|

| Material Type | Thermoplastic polymer | Amorphous thermoplastic |

| Density | 0.90-0.91 g/cm3 | 1.20 g/cm3 |

| Tensile Strength | 30-40 MPa | 55-75 MPa |

| Impact Resistance | Moderate | High, excellent toughness |

| Transparency | Opaque or translucent | Highly transparent |

| Heat Resistance | Melting point ~160degC | Glass transition ~147degC |

| Chemical Resistance | Good against acids and alkalis | Moderate, sensitive to hydrocarbons |

| Applications | Packaging, automotive parts, textiles | Optical lenses, electronics, safety equipment |

| Cost | Low-cost polymer | Higher cost due to performance |

Introduction to Polypropylene and Polycarbonate

Polypropylene is a thermoplastic polymer widely used in packaging, automotive parts, and textiles due to its high chemical resistance, fatigue durability, and low cost. Polycarbonate, a transparent amorphous polymer, offers exceptional impact resistance, optical clarity, and heat resistance, making it ideal for applications like eyewear lenses, electronic components, and automotive glazing. Both polymers serve diverse industrial purposes but differ significantly in mechanical properties and transparency.

Chemical Structure Comparison

Polypropylene is a thermoplastic polymer made from propylene monomers, characterized by a saturated hydrocarbon backbone with methyl side groups, contributing to its chemical resistance and non-polar nature. Polycarbonate consists of carbonate groups (-O-(C=O)-O-) linked by aromatic phenyl rings, providing high impact resistance and thermal stability due to its rigid, polar structure. The key chemical structure difference is that polypropylene is a non-polar polyolefin with simple hydrocarbon chains, whereas polycarbonate is a polar polymer containing ester linkages and aromatic rings.

Mechanical Properties: Strength and Flexibility

Polypropylene exhibits excellent flexibility and moderate strength, making it ideal for applications requiring impact resistance and fatigue endurance. Polycarbonate offers superior mechanical strength and rigidity, with high tensile strength and excellent impact resistance, suitable for demanding structural applications. The choice between polypropylene and polycarbonate depends on the need for flexibility versus mechanical robustness in the intended use.

Thermal Resistance and Performance

Polycarbonate offers superior thermal resistance with a glass transition temperature around 147degC, making it suitable for high-temperature applications compared to polypropylene's lower melting point near 160degC but a glass transition temperature around -20degC, which limits its thermal stability. Polycarbonate maintains mechanical strength and dimensional stability at elevated temperatures, whereas polypropylene tends to soften and deform under prolonged heat exposure. This makes polycarbonate a preferred choice for applications demanding enhanced thermal performance and durability under thermal stress.

Optical Clarity and Aesthetic Qualities

Polycarbonate exhibits superior optical clarity compared to polypropylene, with a light transmittance of approximately 88-90%, making it ideal for applications requiring transparent, glass-like appearance. Polypropylene typically has lower clarity and a more translucent or opaque finish, limiting its use where high visual aesthetics are essential. The choice between these polymers depends heavily on the need for clear visibility and premium aesthetics versus cost-effectiveness and chemical resistance.

Chemical Resistance and Environmental Stability

Polypropylene exhibits excellent chemical resistance to acids, bases, and solvents, making it ideal for containers and piping systems exposed to harsh chemicals. Polycarbonate offers superior environmental stability with higher impact resistance and UV resistance, suited for outdoor applications and durable components. While polypropylene resists chemical degradation, polycarbonate withstands mechanical stress and prolonged environmental exposure.

Ease of Processing and Manufacturing

Polypropylene offers superior ease of processing with its low melting point around 160degC, enabling faster cycle times and energy-efficient manufacturing through injection molding and extrusion. Polycarbonate requires higher processing temperatures near 300degC and more controlled cooling to avoid defects, increasing complexity and cost in production. Manufacturers prefer polypropylene for large-volume, cost-sensitive applications due to its simpler processing and adaptability.

Cost Analysis and Market Availability

Polypropylene generally offers a lower cost per kilogram compared to polycarbonate, making it a preferred choice for budget-sensitive applications. Polycarbonate exhibits higher market availability in specialized sectors requiring superior impact resistance and optical clarity, despite its premium price. The cost differential is influenced by raw material complexity and processing requirements, impacting supply chain dynamics and end-user pricing models.

Common Applications in Industry

Polypropylene is widely used in packaging, automotive parts, and consumer goods due to its chemical resistance and flexibility. Polycarbonate finds extensive applications in electronics, medical devices, and optical lenses because of its high impact resistance and transparency. Both polymers serve distinct roles in industry, with polypropylene favored for lightweight, cost-effective products and polycarbonate chosen for durability and clarity requirements.

Sustainability and Recycling Considerations

Polypropylene (PP) offers superior recyclability and lower environmental impact due to its simpler molecular structure and widespread acceptance in recycling streams compared to polycarbonate (PC). Polycarbonate contains bisphenol A (BPA), posing challenges for safe recycling and raising sustainability concerns linked to chemical contamination. The mechanical robustness of polycarbonate supports longer product lifespans, but polypropylene's efficient recycling infrastructure enhances its overall sustainability profile in circular economy models.

Polypropylene vs Polycarbonate Infographic

materialdif.com

materialdif.com