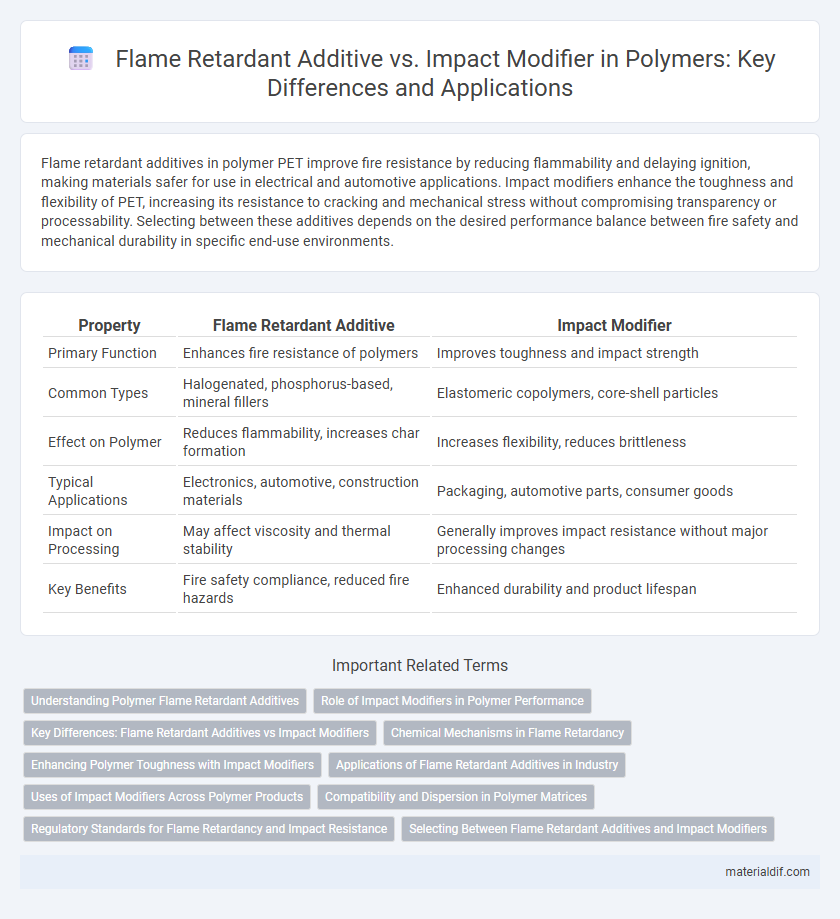

Flame retardant additives in polymer PET improve fire resistance by reducing flammability and delaying ignition, making materials safer for use in electrical and automotive applications. Impact modifiers enhance the toughness and flexibility of PET, increasing its resistance to cracking and mechanical stress without compromising transparency or processability. Selecting between these additives depends on the desired performance balance between fire safety and mechanical durability in specific end-use environments.

Table of Comparison

| Property | Flame Retardant Additive | Impact Modifier |

|---|---|---|

| Primary Function | Enhances fire resistance of polymers | Improves toughness and impact strength |

| Common Types | Halogenated, phosphorus-based, mineral fillers | Elastomeric copolymers, core-shell particles |

| Effect on Polymer | Reduces flammability, increases char formation | Increases flexibility, reduces brittleness |

| Typical Applications | Electronics, automotive, construction materials | Packaging, automotive parts, consumer goods |

| Impact on Processing | May affect viscosity and thermal stability | Generally improves impact resistance without major processing changes |

| Key Benefits | Fire safety compliance, reduced fire hazards | Enhanced durability and product lifespan |

Understanding Polymer Flame Retardant Additives

Polymer flame retardant additives enhance material resistance to ignition and reduce flame spread by interfering with combustion processes at the molecular level. Unlike impact modifiers that primarily improve polymer toughness and impact strength, flame retardant additives often incorporate elements such as phosphorus, bromine, or aluminium hydroxide to form protective char layers or release flame-inhibiting gases. Optimal flame retardant selection depends on polymer type, processing conditions, and regulatory compliance to ensure fire safety without compromising mechanical properties.

Role of Impact Modifiers in Polymer Performance

Impact modifiers enhance polymer performance by improving toughness and resistance to cracking under stress, crucial for applications requiring durability and flexibility. Unlike flame retardant additives that focus on reducing flammability, impact modifiers optimize mechanical properties without compromising the polymer's processability. The integration of impact modifiers leads to superior impact strength, elongation at break, and enhanced overall polymer resilience in demanding environments.

Key Differences: Flame Retardant Additives vs Impact Modifiers

Flame retardant additives in polymers are specifically formulated to enhance fire resistance by inhibiting ignition and slowing combustion, often containing elements like halogens, phosphorus, or minerals such as aluminum hydroxide. Impact modifiers improve a polymer's toughness and resistance to mechanical stress without significantly altering the material's fire performance, typically based on elastomeric additives that absorb and dissipate impact energy. The key difference lies in their primary function: flame retardant additives focus on safety and fire prevention, while impact modifiers emphasize mechanical durability and impact resistance.

Chemical Mechanisms in Flame Retardancy

Flame retardant additives function by interfering with the combustion process through mechanisms such as promoting char formation, releasing radicals that quench flame-propagating species, or diluting combustible gases via endothermic decomposition. In contrast, impact modifiers primarily enhance polymer toughness through energy absorption and stress distribution without significantly altering the chemical pathways involved in flame resistance. Understanding the distinct chemical mechanisms from flame retardant additives is crucial for developing polymers that balance both enhanced fire safety and mechanical performance.

Enhancing Polymer Toughness with Impact Modifiers

Impact modifiers significantly enhance polymer toughness by improving resistance to crack initiation and propagation, making materials more durable under mechanical stress. Unlike flame retardant additives that primarily reduce flammability, impact modifiers increase energy absorption and flexibility in polymers such as polypropylene and PVC. Incorporating elastomeric impact modifiers like ABS or MBS copolymers optimizes impact strength without compromising transparency or processability.

Applications of Flame Retardant Additives in Industry

Flame retardant additives are essential in polymers used across the electronics, automotive, and construction industries, enhancing fire resistance and compliance with safety regulations. These additives improve the material's ability to withstand high temperatures and inhibit ignition, critical for components such as circuit boards, automotive interiors, and insulation panels. Unlike impact modifiers that enhance mechanical toughness, flame retardant additives focus on reducing flammability and smoke emission, thereby extending the polymer's application in safety-sensitive environments.

Uses of Impact Modifiers Across Polymer Products

Impact modifiers enhance the toughness and flexibility of polymer products such as polyethylene, polypropylene, and PVC by improving resistance to cracking and impact damage. They are widely used in automotive components, packaging films, and household appliances to extend product durability and performance under mechanical stress. Unlike flame retardant additives that focus on reducing flammability, impact modifiers primarily target mechanical property enhancement in polymer formulations.

Compatibility and Dispersion in Polymer Matrices

Flame retardant additives and impact modifiers differ significantly in compatibility and dispersion within polymer matrices. Flame retardants often require specialized surface treatments or compatibilizers to achieve uniform dispersion and prevent phase separation, enhancing fire resistance without compromising mechanical properties. Impact modifiers are typically designed for better compatibility with the polymer matrix, promoting homogeneous dispersion that improves toughness and impact strength without adversely affecting processability.

Regulatory Standards for Flame Retardancy and Impact Resistance

Flame retardant additives must comply with stringent regulatory standards such as UL 94, EN 13501-1, and NFPA 701 to ensure materials meet fire safety requirements in polymer applications. Impact modifiers are governed by impact resistance standards like ASTM D256 and ISO 179 for toughness and durability enhancement in polymers. Regulatory compliance ensures that flame retardant additives effectively reduce flammability without compromising mechanical performance, while impact modifiers must enhance toughness without negatively affecting polymer processability.

Selecting Between Flame Retardant Additives and Impact Modifiers

Selecting between flame retardant additives and impact modifiers depends primarily on the polymer's intended application and performance requirements. Flame retardant additives enhance a polymer's resistance to ignition and combustion, crucial for electrical components and construction materials, while impact modifiers improve toughness and resistance to mechanical stress, ideal for automotive parts and packaging. Evaluating factors such as thermal stability, mechanical properties, and regulatory compliance ensures optimal additive selection for polymer formulations.

Flame Retardant Additive vs Impact Modifier Infographic

materialdif.com

materialdif.com