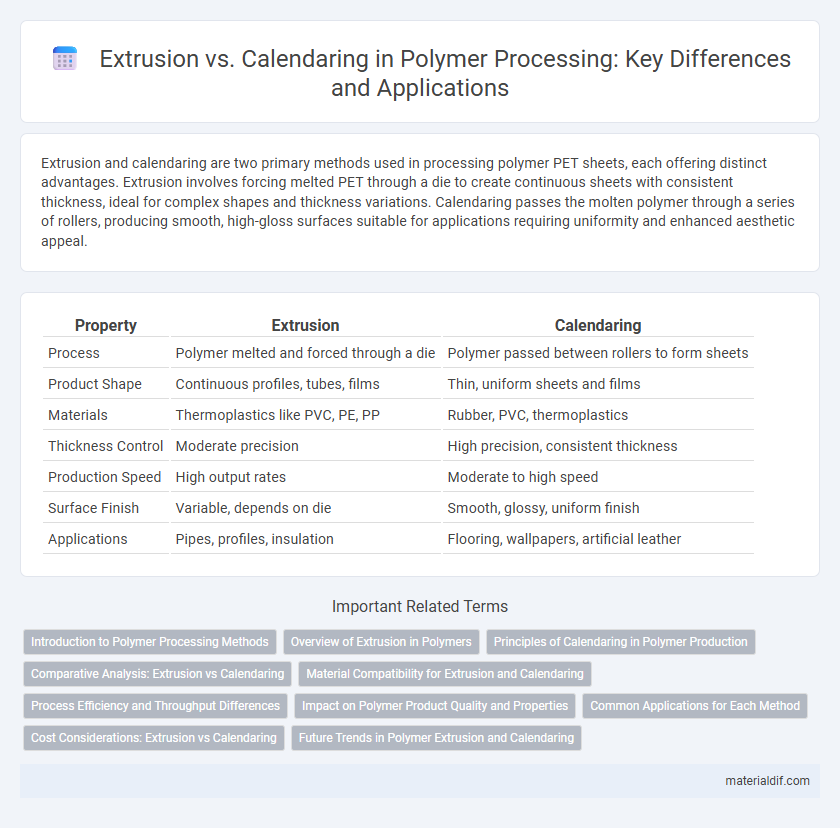

Extrusion and calendaring are two primary methods used in processing polymer PET sheets, each offering distinct advantages. Extrusion involves forcing melted PET through a die to create continuous sheets with consistent thickness, ideal for complex shapes and thickness variations. Calendaring passes the molten polymer through a series of rollers, producing smooth, high-gloss surfaces suitable for applications requiring uniformity and enhanced aesthetic appeal.

Table of Comparison

| Property | Extrusion | Calendaring |

|---|---|---|

| Process | Polymer melted and forced through a die | Polymer passed between rollers to form sheets |

| Product Shape | Continuous profiles, tubes, films | Thin, uniform sheets and films |

| Materials | Thermoplastics like PVC, PE, PP | Rubber, PVC, thermoplastics |

| Thickness Control | Moderate precision | High precision, consistent thickness |

| Production Speed | High output rates | Moderate to high speed |

| Surface Finish | Variable, depends on die | Smooth, glossy, uniform finish |

| Applications | Pipes, profiles, insulation | Flooring, wallpapers, artificial leather |

Introduction to Polymer Processing Methods

Extrusion and calendaring are fundamental polymer processing methods used to shape thermoplastic materials. Extrusion forces molten polymer through a shaped die to create continuous profiles like pipes and films, optimizing production efficiency for complex cross-sections. Calendaring involves passing polymer melts through heated rollers to produce smooth, uniform sheets with controlled thickness, ideal for films, coatings, and laminates.

Overview of Extrusion in Polymers

Extrusion in polymers is a continuous manufacturing process where molten polymer is forced through a shaped die to create products with uniform cross-sections, such as pipes, sheets, and films. This method offers precise control over dimensions and thickness, enabling high production efficiency for complex profiles. Extrusion is widely used due to its versatility, cost-effectiveness, and ability to process a broad range of thermoplastic and thermosetting materials.

Principles of Calendaring in Polymer Production

Calendaring in polymer production involves passing molten polymer through a series of heated rollers to form thin, uniform sheets with controlled thickness and surface finish. This process enables precise control over film properties such as gloss, opacity, and texture by adjusting roller speed, temperature, and gap. Unlike extrusion, calendaring produces highly consistent sheet materials ideal for applications requiring smooth surfaces and dimensional accuracy.

Comparative Analysis: Extrusion vs Calendaring

Extrusion and calendaring are key polymer processing techniques with distinct advantages based on product requirements. Extrusion excels in producing continuous profiles like pipes and sheets with uniform cross-sections, while calendaring offers superior surface finish and precise thickness control in thin films and coated fabrics. The choice depends on factors such as material viscosity, desired product geometry, and production speed, where extrusion suits high-volume runs and calendaring supports flexible design customization.

Material Compatibility for Extrusion and Calendaring

Extrusion suits thermoplastics like polyethylene, polypropylene, and PVC due to their melt-flow properties enabling continuous shaping through dies. Calendaring excels with polymers such as PVC, rubber, and thermoplastic elastomers, offering precise thickness control and smooth surface finishes by passing material through rollers. Material compatibility for extrusion demands melt viscosity and thermal stability, whereas calendaring requires polymers with sufficient tackiness and plasticity to form thin, uniform sheets without cracking.

Process Efficiency and Throughput Differences

Extrusion achieves higher throughput by continuously forcing molten polymer through a shaped die, enabling rapid production of tubes, films, and profiles with consistent cross-sections. Calendaring involves passing polymer melts through rollers to form thin sheets or films, which typically results in lower process efficiency due to slower speeds and increased energy consumption. Extrusion's streamlined operation facilitates greater process efficiency compared to the batch-like, multi-pass nature of calendaring, making it preferable for high-volume manufacturing.

Impact on Polymer Product Quality and Properties

Extrusion enhances polymer product quality by enabling continuous production with controlled thickness, improved mechanical strength, and consistent surface finish, ideal for pipes and films. Calendaring offers superior surface smoothness and uniform thickness, crucial for flexible sheets and coatings, but may introduce internal stresses affecting durability. Selecting between extrusion and calendaring depends on desired polymer properties like tensile strength, clarity, and dimensional stability.

Common Applications for Each Method

Extrusion is commonly used for producing pipes, tubing, and plastic films due to its ability to create continuous shapes with uniform cross-sections. Calendaring is primarily applied in manufacturing flexible vinyl sheets, coated fabrics, and synthetic leather, offering precise control over thickness and surface finish. Both methods are essential in polymer processing, tailored to specific product requirements and material properties.

Cost Considerations: Extrusion vs Calendaring

Extrusion generally incurs lower initial equipment costs compared to calendaring, making it more cost-effective for large-scale or continuous production of polymer sheets and profiles. Calendaring demands higher maintenance expenses due to the precision rollers and more intricate machinery involved, increasing operational costs over time. The choice between extrusion and calendaring largely depends on the specific product requirements, production volume, and budget constraints, with extrusion favored for cost efficiency and calendaring providing superior surface finish and thickness control.

Future Trends in Polymer Extrusion and Calendaring

Future trends in polymer extrusion and calendaring emphasize enhanced automation and real-time process control using AI-driven monitoring systems, which improve precision and efficiency. Advances in sustainable materials and eco-friendly polymers are increasingly integrated into both extrusion and calendaring processes to reduce environmental impact. Digital twins and Industry 4.0 technologies enable predictive maintenance and optimized production workflows, fostering smarter manufacturing in polymer processing.

Extrusion vs Calendaring Infographic

materialdif.com

materialdif.com