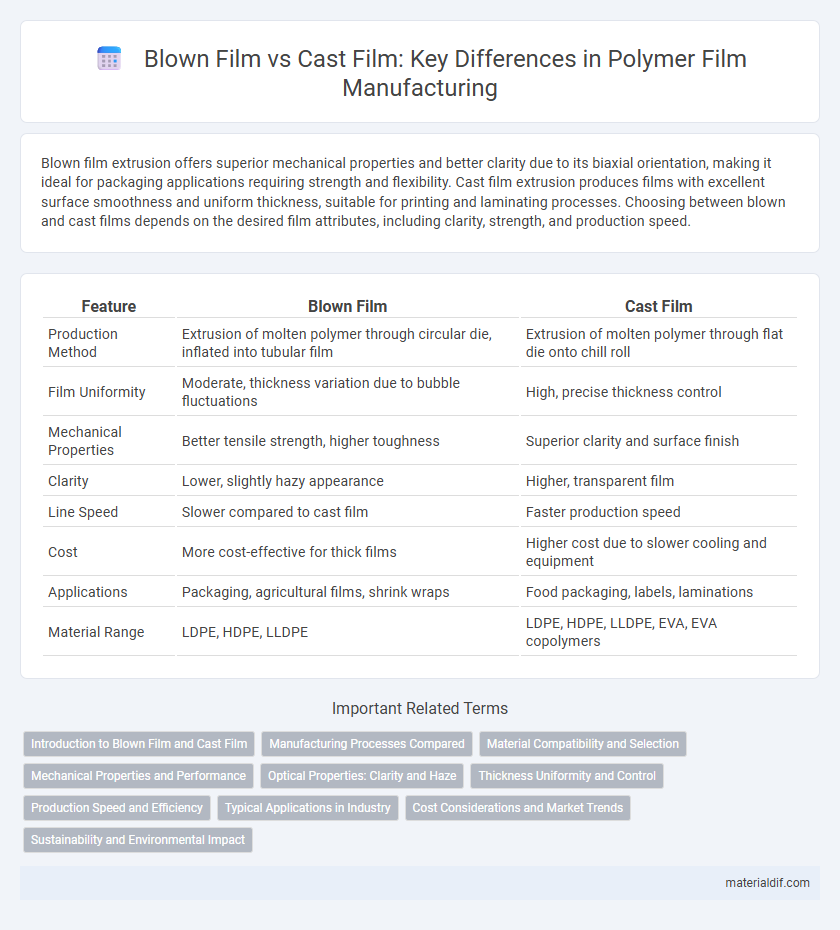

Blown film extrusion offers superior mechanical properties and better clarity due to its biaxial orientation, making it ideal for packaging applications requiring strength and flexibility. Cast film extrusion produces films with excellent surface smoothness and uniform thickness, suitable for printing and laminating processes. Choosing between blown and cast films depends on the desired film attributes, including clarity, strength, and production speed.

Table of Comparison

| Feature | Blown Film | Cast Film |

|---|---|---|

| Production Method | Extrusion of molten polymer through circular die, inflated into tubular film | Extrusion of molten polymer through flat die onto chill roll |

| Film Uniformity | Moderate, thickness variation due to bubble fluctuations | High, precise thickness control |

| Mechanical Properties | Better tensile strength, higher toughness | Superior clarity and surface finish |

| Clarity | Lower, slightly hazy appearance | Higher, transparent film |

| Line Speed | Slower compared to cast film | Faster production speed |

| Cost | More cost-effective for thick films | Higher cost due to slower cooling and equipment |

| Applications | Packaging, agricultural films, shrink wraps | Food packaging, labels, laminations |

| Material Range | LDPE, HDPE, LLDPE | LDPE, HDPE, LLDPE, EVA, EVA copolymers |

Introduction to Blown Film and Cast Film

Blown film and cast film are two primary methods for producing polymer films, each offering distinct manufacturing processes and material properties. Blown film involves extruding molten polymer through a circular die, inflating it into a tubular shape before cooling, resulting in films with balanced mechanical strength and superior clarity. Cast film is produced by extruding molten polymer onto a chilled roller, yielding films with consistent thickness and excellent surface smoothness, commonly used in high-quality packaging applications.

Manufacturing Processes Compared

Blown film manufacturing involves extruding molten polymer through a circular die, followed by air inflation to form a thin tubular film, which is then collapsed and rolled. Cast film production extrudes polymer through a flat die onto chilled rollers, solidifying the film via rapid cooling. Blown film offers better mechanical properties and thickness uniformity, while cast film enables higher production speeds and clearer films.

Material Compatibility and Selection

Blown film and cast film processes differ significantly in material compatibility, with blown film favoring polyethylenes like LDPE and LLDPE due to their high melt strength and flexibility, while cast film allows greater versatility, accommodating materials such as polypropylene, EVA, and nylon for enhanced clarity and strength. Material selection in blown film requires polymers that withstand higher shear and cooling rates, impacting molecular orientation and film properties, whereas cast film benefits from controlled cooling to optimize uniformity and optical characteristics. Choosing between blown and cast film depends on polymer properties, desired film thickness, mechanical strength, and end-use application, influencing barrier performance and printability.

Mechanical Properties and Performance

Blown film typically exhibits superior mechanical properties such as higher tensile strength and better impact resistance due to its biaxial orientation during the extrusion process, making it ideal for packaging applications requiring durability. Cast film, produced by cooling extruded polymer on a chilled roll, offers excellent clarity and uniform thickness but generally has lower tensile strength and elongation compared to blown film. Performance differences also include better sealability and gloss in cast films, while blown films provide enhanced puncture resistance and flexibility.

Optical Properties: Clarity and Haze

Blown film typically exhibits higher haze and lower clarity due to its slower cooling process, which causes more crystalline structures to form in the polymer matrix. In contrast, cast film is rapidly cooled on chilled rollers, resulting in superior optical properties with higher clarity and lower haze levels. These differences make cast film more suitable for applications requiring transparent packaging and excellent visual appeal.

Thickness Uniformity and Control

Blown film extrusion offers superior thickness uniformity due to the radial stretching and cooling process, which allows for consistent film gauge control across the bubble circumference. In contrast, cast film extrusion achieves thickness control through precise linear drawing and cooling on chilled rollers, resulting in better flatness but slightly less uniformity in thickness compared to blown films. Manufacturers often choose blown film for applications requiring higher gauge consistency and cast film for products needing exceptional surface smoothness and dimensional stability.

Production Speed and Efficiency

Blown film extrusion typically achieves production speeds between 20 to 100 meters per minute, offering superior thickness uniformity and better mechanical properties due to biaxial orientation, which enhances efficiency in packaging applications. Cast film extrusion, while generally slower at 15 to 50 meters per minute, excels in producing films with smoother surfaces and higher optical clarity, making it efficient for specialty films requiring precision. Selecting blown film optimizes throughput for high-volume production, whereas cast film prioritizes quality control in lower-speed, high-precision manufacturing environments.

Typical Applications in Industry

Blown film offers superior strength and clarity, making it ideal for flexible packaging, agricultural films, and industrial liner applications. Cast film provides excellent surface smoothness and uniform thickness, preferred for printable packaging, medical device films, and laminates. Both technologies serve critical roles in packaging, with choices driven by specific industry needs such as durability, clarity, and production speed.

Cost Considerations and Market Trends

Blown film production involves higher energy consumption and slower output rates compared to cast film, resulting in increased operational costs but offering superior strength and versatility for packaging applications. Cast film processes benefit from lower energy use and faster production speeds, making them cost-effective for high-volume markets like food packaging and medical supplies. Market trends show a growing preference for cast films due to advancements in extrusion technology and demand for lightweight, clear films, while blown films maintain strong demand in applications requiring durability and barrier properties.

Sustainability and Environmental Impact

Blown film production typically consumes more energy than cast film due to the higher cooling and air inflation requirements, impacting its overall carbon footprint. Cast film processes offer better material efficiency with less waste generation and easier recycling potential, contributing to improved environmental sustainability. Both technologies can optimize sustainability by integrating bio-based polymers and energy-efficient machinery, reducing their environmental impact throughout the product lifecycle.

Blown Film vs Cast Film Infographic

materialdif.com

materialdif.com