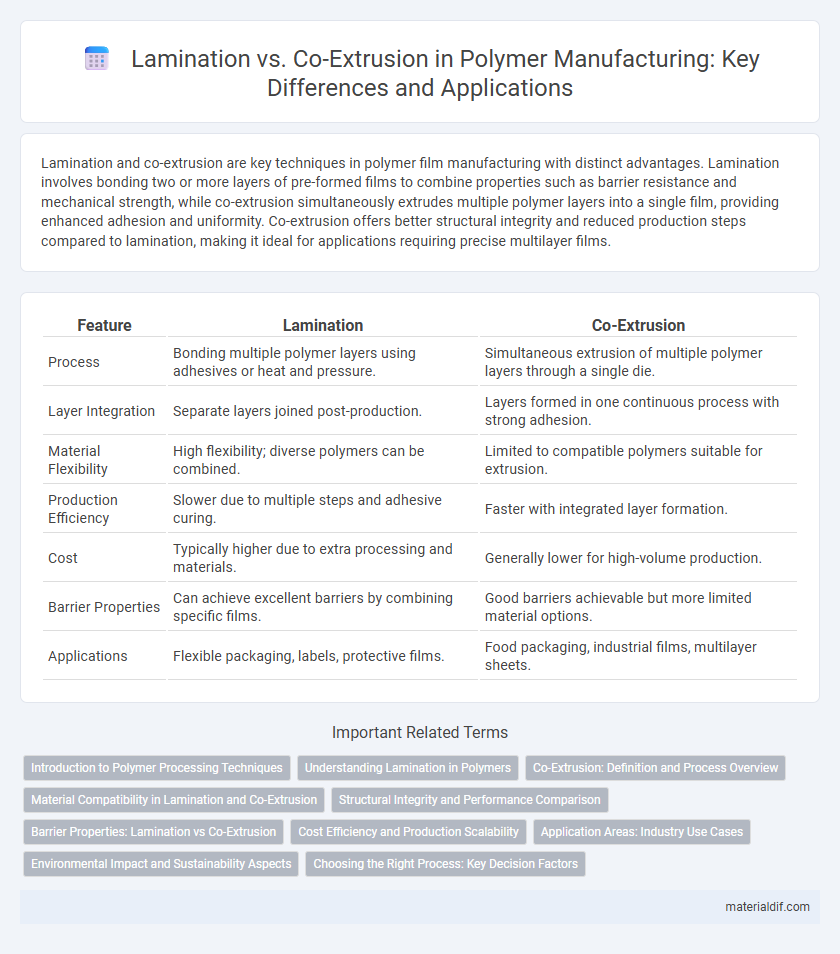

Lamination and co-extrusion are key techniques in polymer film manufacturing with distinct advantages. Lamination involves bonding two or more layers of pre-formed films to combine properties such as barrier resistance and mechanical strength, while co-extrusion simultaneously extrudes multiple polymer layers into a single film, providing enhanced adhesion and uniformity. Co-extrusion offers better structural integrity and reduced production steps compared to lamination, making it ideal for applications requiring precise multilayer films.

Table of Comparison

| Feature | Lamination | Co-Extrusion |

|---|---|---|

| Process | Bonding multiple polymer layers using adhesives or heat and pressure. | Simultaneous extrusion of multiple polymer layers through a single die. |

| Layer Integration | Separate layers joined post-production. | Layers formed in one continuous process with strong adhesion. |

| Material Flexibility | High flexibility; diverse polymers can be combined. | Limited to compatible polymers suitable for extrusion. |

| Production Efficiency | Slower due to multiple steps and adhesive curing. | Faster with integrated layer formation. |

| Cost | Typically higher due to extra processing and materials. | Generally lower for high-volume production. |

| Barrier Properties | Can achieve excellent barriers by combining specific films. | Good barriers achievable but more limited material options. |

| Applications | Flexible packaging, labels, protective films. | Food packaging, industrial films, multilayer sheets. |

Introduction to Polymer Processing Techniques

Lamination and co-extrusion are essential polymer processing techniques used to create multi-layered materials with enhanced properties. Lamination involves bonding pre-formed polymer films or sheets using adhesives or heat, optimizing barrier performance and mechanical strength. Co-extrusion simultaneously melts and extrudes multiple polymers through a single die, enabling precise layer integration and improved material uniformity for packaging and industrial applications.

Understanding Lamination in Polymers

Lamination in polymers involves bonding multiple layers of film or sheet materials using adhesives, heat, or pressure to create a composite structure with enhanced barrier, mechanical, and aesthetic properties. This process allows for combining different polymer types or integrating functional layers such as barrier films, inks, or foils without altering the individual layer characteristics. Lamination offers flexibility in material selection and customization, making it ideal for packaging applications requiring improved durability, moisture resistance, and printability compared to co-extrusion, which fuses layers during the molten polymer stage.

Co-Extrusion: Definition and Process Overview

Co-extrusion is a polymer manufacturing process that involves the simultaneous extrusion of multiple polymer layers through a single die to create a multilayer film or sheet with enhanced properties. This process allows precise control over the thickness and composition of each layer, enabling the production of materials with tailored barrier, mechanical, and optical characteristics. Co-extrusion improves performance and reduces material usage compared to lamination by integrating the layers during extrusion rather than bonding them afterward.

Material Compatibility in Lamination and Co-Extrusion

Material compatibility in lamination involves bonding different polymers using adhesives or heat, which allows the combination of materials with varying properties but may pose challenges due to adhesive selection and interfacial adhesion strength. Co-extrusion achieves material compatibility by simultaneously extruding multiple polymer melts through a single die, creating a multilayer structure with strong interfacial bonding and improved barrier properties without using adhesives. Lamination offers flexibility with diverse materials but risks delamination, while co-extrusion ensures integral layer integration, optimizing mechanical performance and material synergy.

Structural Integrity and Performance Comparison

Lamination involves bonding multiple polymer layers through adhesives or heat, offering enhanced barrier properties but potential delamination under stress, impacting structural integrity. Co-extrusion creates a unified multilayer polymer structure in a single process, ensuring superior interlayer adhesion and consistent mechanical performance. Co-extruded films typically exhibit higher tensile strength, improved flexibility, and better resistance to environmental factors compared to laminated counterparts, making them ideal for demanding applications.

Barrier Properties: Lamination vs Co-Extrusion

Lamination provides strong barrier properties by physically bonding multiple layers, often combining different polymer films and adhesives to enhance resistance against moisture, oxygen, and contaminants. Co-extrusion forms multilayer polymer sheets or films during the extrusion process, enabling precise control over each layer's thickness and composition, which results in superior, uniform barrier performance. Co-extruded films often exhibit better moisture vapor transmission rates (MVTR) and oxygen transmission rates (OTR) than laminated structures, making them ideal for high-barrier packaging applications.

Cost Efficiency and Production Scalability

Lamination offers cost efficiency through lower initial equipment investment and simpler process control but can face limitations in production scalability due to longer cycle times and higher labor costs. Co-extrusion enhances production scalability by enabling continuous multi-layer polymer film formation in a single operation, reducing material waste and improving throughput. While co-extrusion requires higher capital expenditure, its ability to produce complex barrier structures at scale delivers long-term cost savings in high-volume applications.

Application Areas: Industry Use Cases

Lamination is widely used in packaging industries for food and pharmaceuticals due to its excellent barrier properties and surface finish, enhancing product protection and shelf life. Co-extrusion finds applications in multi-layer films for automotive, agriculture, and medical sectors, offering tailored mechanical strength and chemical resistance through integrated polymer layers. Both methods support sustainable packaging solutions by enabling material optimization and recyclability in various industrial applications.

Environmental Impact and Sustainability Aspects

Lamination and co-extrusion in polymer manufacturing differ significantly in environmental impact; lamination often involves multiple layers of adhesives that complicate recycling and increase waste, while co-extrusion creates multi-layer films bonded during extrusion, enhancing recyclability by using compatible polymers. Co-extrusion typically consumes less energy and generates fewer volatile organic compounds (VOCs) compared to lamination, contributing to a lower carbon footprint. Sustainable packaging strategies increasingly favor co-extrusion for its efficiency and improved end-of-life disposal options, supporting circular economy goals in the polymer industry.

Choosing the Right Process: Key Decision Factors

Selecting between lamination and co-extrusion depends on factors such as material compatibility, barrier properties, production speed, and cost-effectiveness. Lamination offers superior adhesion for dissimilar substrates, ideal for flexible packaging requiring strong multi-layer bonding. Co-extrusion enables seamless multi-layer films with enhanced barrier performance and reduced production steps, making it suitable for high-volume processes needing consistent quality.

Lamination vs Co-Extrusion Infographic

materialdif.com

materialdif.com