Antistatic polymers reduce surface static electricity by dissipating charges slowly, preventing dust attraction and static shocks in electronic and packaging applications. Conductive polymers, on the other hand, exhibit intrinsic electrical conductivity due to their conjugated polymer chain structures, enabling their use in sensors, flexible electronics, and electromagnetic shielding. While antistatic polymers primarily manage surface charge buildup, conductive polymers actively conduct electricity through their molecular framework.

Table of Comparison

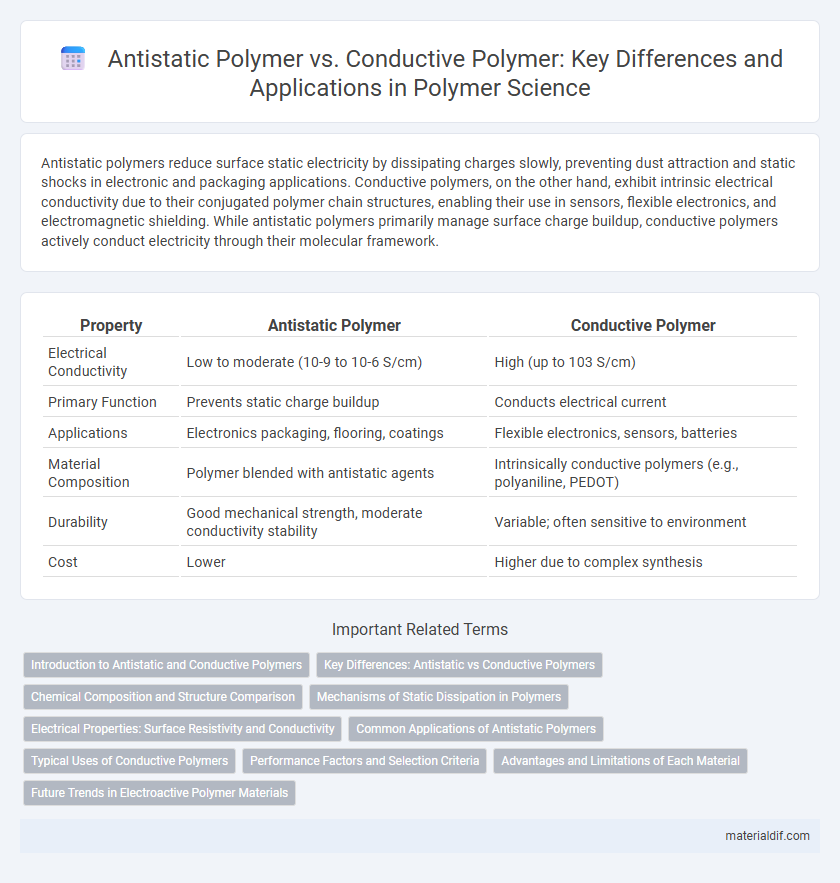

| Property | Antistatic Polymer | Conductive Polymer |

|---|---|---|

| Electrical Conductivity | Low to moderate (10-9 to 10-6 S/cm) | High (up to 103 S/cm) |

| Primary Function | Prevents static charge buildup | Conducts electrical current |

| Applications | Electronics packaging, flooring, coatings | Flexible electronics, sensors, batteries |

| Material Composition | Polymer blended with antistatic agents | Intrinsically conductive polymers (e.g., polyaniline, PEDOT) |

| Durability | Good mechanical strength, moderate conductivity stability | Variable; often sensitive to environment |

| Cost | Lower | Higher due to complex synthesis |

Introduction to Antistatic and Conductive Polymers

Antistatic polymers exhibit surface resistivity typically between 10^9 and 10^12 ohms per square, effectively reducing static charge buildup without significantly altering the material's inherent insulating properties. Conductive polymers, such as polyaniline and polythiophene, possess intrinsic electrical conductivity due to conjugated polymer backbones allowing charge delocalization, enabling applications in flexible electronics and electromagnetic interference shielding. Both polymer types enhance performance in electronics and packaging by controlling electrostatic discharge through distinct mechanisms tailored to resistivity requirements.

Key Differences: Antistatic vs Conductive Polymers

Antistatic polymers reduce surface static charge by dissipating small amounts of electricity, preventing dust attraction and static discharge without conducting significant current. Conductive polymers possess intrinsic electrical conductivity, allowing them to carry substantial electrical current useful in electronic devices and sensors. Key differences include conductivity levels, with antistatic polymers exhibiting moderate dissipation properties suitable for protective coatings, while conductive polymers enable functionality in applications demanding active electrical conduction.

Chemical Composition and Structure Comparison

Antistatic polymers typically incorporate conductive additives like carbon black or conductive fillers within an insulating polymer matrix to reduce surface resistivity without forming a continuous conductive path. Conductive polymers possess conjugated backbone structures, such as polyaniline or polythiophene, enabling intrinsic electrical conductivity through delocalized p-electrons. The chemical composition difference lies in antistatic polymers relying on dispersed conductive particles, whereas conductive polymers have inherently conductive molecular architectures.

Mechanisms of Static Dissipation in Polymers

Antistatic polymers dissipate static electricity primarily through surface conductivity achieved by incorporating low levels of conductive additives or hydrophilic groups that attract moisture, facilitating charge leakage. Conductive polymers, in contrast, possess intrinsic conjugated polymer backbones, such as polyaniline or polythiophene, enabling electron mobility and bulk conductivity for efficient static dissipation. The static dissipation mechanism in antistatic polymers relies on surface charge neutralization, whereas conductive polymers enable deeper charge transport throughout the material matrix.

Electrical Properties: Surface Resistivity and Conductivity

Antistatic polymers exhibit surface resistivity values typically ranging from 10^9 to 10^12 ohms per square, effectively dissipating static charges without allowing significant current flow. Conductive polymers display much lower surface resistivity, often below 10^5 ohms per square, allowing higher electrical conductivity essential for applications like EMI shielding and flexible electronics. These differences in electrical properties stem from the intrinsic molecular structure and doping levels, influencing electron mobility and charge carrier density.

Common Applications of Antistatic Polymers

Antistatic polymers are widely used in packaging materials, electronic device housings, and automotive components to prevent static electricity buildup that can damage sensitive electronics or attract dust. Their ability to dissipate static charges makes them ideal for environments requiring controlled static conditions, such as cleanrooms and semiconductor manufacturing. These polymers are also common in consumer goods like flooring and carpets to enhance safety by reducing electrostatic discharge.

Typical Uses of Conductive Polymers

Conductive polymers are primarily used in flexible electronics, sensors, electromagnetic shielding, and organic photovoltaic cells due to their ability to conduct electricity while maintaining polymeric properties. These materials enable innovations in wearable devices, antistatic coatings, and transparent conductive films for displays and touchscreens. Their adaptability and conductivity make them essential in applications requiring lightweight, corrosion-resistant, and mechanically flexible components.

Performance Factors and Selection Criteria

Antistatic polymers reduce surface electrical charge by incorporating additives like carbon black or conductive fillers, improving safety and preventing dust attraction without significantly altering mechanical properties. Conductive polymers possess intrinsic electrical conductivity through conjugated molecular structures, enabling applications in flexible electronics and sensors, but may require precise processing to maintain stability and performance. Selection criteria depend on required conductivity levels, environmental conditions, mechanical robustness, and cost, with antistatic polymers favored for moderate static control and conductive polymers chosen for advanced electronic functionalities.

Advantages and Limitations of Each Material

Antistatic polymers effectively reduce static electricity buildup, enhancing safety in electronic packaging and preventing dust attraction, but typically possess limited electrical conductivity and may require surface treatments for long-lasting performance. Conductive polymers offer higher electrical conductivity suitable for applications like flexible electronics and sensors, yet they can be more expensive and less mechanically durable under stress compared to antistatic variants. Selection depends on balancing conductivity requirements with cost, durability, and specific application environments.

Future Trends in Electroactive Polymer Materials

Future trends in electroactive polymer materials emphasize the development of advanced antistatic polymers with enhanced surface resistivity control and environmental stability, enabling their use in flexible electronics and wearable devices. Conductive polymers are evolving toward higher conductivity, improved mechanical strength, and biocompatibility, essential for next-generation sensors, energy storage, and biomedical applications. Innovations in nanocomposite integration and molecular doping techniques are driving the performance and multifunctionality of both antistatic and conductive polymers, positioning them as critical components in smart materials and IoT technologies.

Antistatic Polymer vs Conductive Polymer Infographic

materialdif.com

materialdif.com