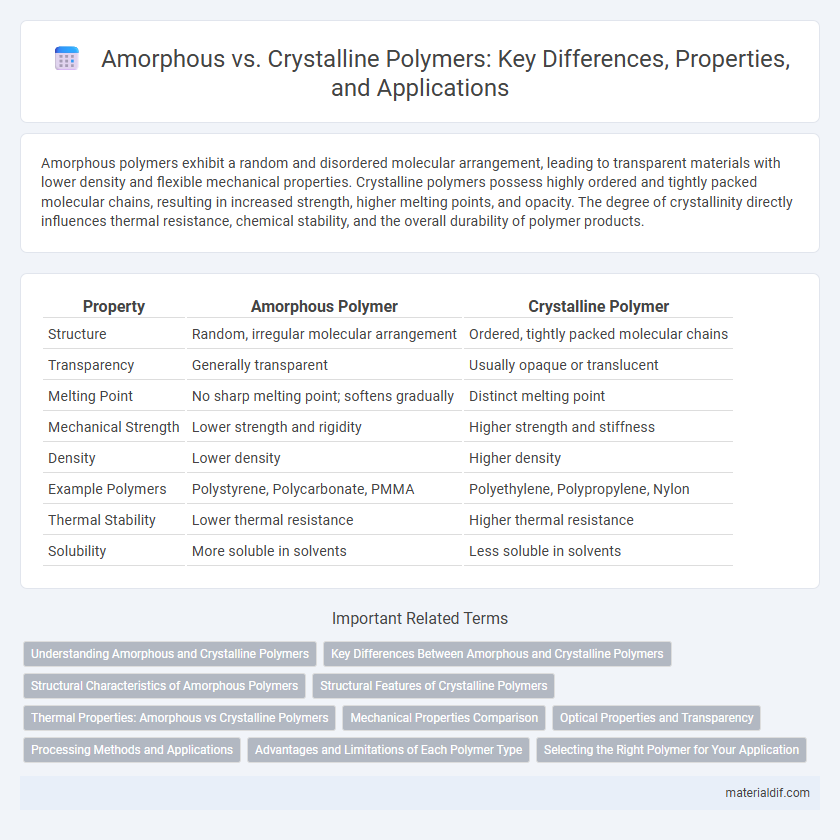

Amorphous polymers exhibit a random and disordered molecular arrangement, leading to transparent materials with lower density and flexible mechanical properties. Crystalline polymers possess highly ordered and tightly packed molecular chains, resulting in increased strength, higher melting points, and opacity. The degree of crystallinity directly influences thermal resistance, chemical stability, and the overall durability of polymer products.

Table of Comparison

| Property | Amorphous Polymer | Crystalline Polymer |

|---|---|---|

| Structure | Random, irregular molecular arrangement | Ordered, tightly packed molecular chains |

| Transparency | Generally transparent | Usually opaque or translucent |

| Melting Point | No sharp melting point; softens gradually | Distinct melting point |

| Mechanical Strength | Lower strength and rigidity | Higher strength and stiffness |

| Density | Lower density | Higher density |

| Example Polymers | Polystyrene, Polycarbonate, PMMA | Polyethylene, Polypropylene, Nylon |

| Thermal Stability | Lower thermal resistance | Higher thermal resistance |

| Solubility | More soluble in solvents | Less soluble in solvents |

Understanding Amorphous and Crystalline Polymers

Amorphous polymers lack a well-defined, ordered molecular structure, resulting in materials that are transparent, flexible, and have lower melting points compared to crystalline polymers. Crystalline polymers exhibit highly ordered, tightly packed molecular chains, providing enhanced strength, higher density, and distinct melting temperatures due to their crystalline regions. Understanding the degree of crystallinity in polymers is essential for tailoring mechanical properties, thermal behavior, and chemical resistance in applications such as packaging, automotive components, and electronics.

Key Differences Between Amorphous and Crystalline Polymers

Amorphous polymers have a random, disordered molecular structure resulting in transparent, flexible, and less dense materials, while crystalline polymers exhibit a highly ordered, tightly packed arrangement that provides higher density, strength, and opacity. Thermal properties differ significantly; amorphous polymers possess a glass transition temperature (Tg) without a sharp melting point, whereas crystalline polymers have distinct melting temperatures (Tm) due to their ordered regions. Mechanical behavior varies as amorphous polymers tend to be more impact-resistant and ductile, while crystalline polymers show greater tensile strength and stiffness.

Structural Characteristics of Amorphous Polymers

Amorphous polymers exhibit a disordered, non-crystalline molecular structure characterized by randomly arranged polymer chains lacking long-range order. This irregular arrangement results in isotropic properties, increased transparency, and higher impact resistance compared to crystalline polymers. The structural characteristics of amorphous polymers contribute to their lower density, greater flexibility, and broader glass transition temperature range.

Structural Features of Crystalline Polymers

Crystalline polymers exhibit a highly ordered molecular structure characterized by tightly packed polymer chains arranged in a repeating lattice pattern. This regular arrangement results in distinct melting points and increased density compared to amorphous polymers, which lack such order. The degree of crystallinity significantly influences mechanical properties, thermal resistance, and optical clarity of crystalline polymers.

Thermal Properties: Amorphous vs Crystalline Polymers

Amorphous polymers exhibit lower melting points and glass transition temperatures compared to crystalline polymers due to their irregular molecular structures, resulting in less thermal stability. Crystalline polymers have well-ordered, tightly packed chains that enhance thermal resistance and increase melting temperatures, making them suitable for high-temperature applications. The degree of crystallinity directly influences thermal expansion, with crystalline polymers showing higher dimensional stability under heat.

Mechanical Properties Comparison

Amorphous polymers exhibit lower tensile strength and modulus but offer greater impact resistance and flexibility compared to crystalline polymers, which have higher strength and stiffness due to their ordered molecular structure. Crystalline polymers typically display better chemical resistance and dimensional stability, benefiting applications requiring durability under stress. The degree of crystallinity directly influences mechanical properties, making crystalline polymers preferable for load-bearing components while amorphous polymers suit applications needing shock absorption.

Optical Properties and Transparency

Amorphous polymers exhibit high optical clarity due to their random molecular arrangement, which minimizes light scattering and enhances transparency. Crystalline polymers have ordered molecular structures causing light diffraction and reduced transparency, often resulting in a translucent or opaque appearance. These differences in molecular organization directly affect the refractive index and light transmission properties critical for applications requiring optical clarity.

Processing Methods and Applications

Amorphous polymers, characterized by their random molecular arrangement, are typically processed using methods like injection molding and extrusion, making them ideal for applications requiring optical clarity and impact resistance such as packaging and automotive components. Crystalline polymers possess highly ordered structures, processed through techniques like compression molding and blow molding, which enhance their mechanical strength and chemical resistance, suitable for applications in fibers, films, and engineering plastics. Understanding the distinct processing requirements and material properties of amorphous versus crystalline polymers enables optimized selection for specific industrial uses.

Advantages and Limitations of Each Polymer Type

Amorphous polymers offer advantages such as excellent optical clarity, superior impact resistance, and easier processing due to their random molecular arrangement, making them ideal for applications requiring transparency and toughness. However, their limitations include lower chemical resistance and reduced mechanical strength compared to crystalline polymers. Crystalline polymers provide higher tensile strength, enhanced chemical resistance, and better dimensional stability due to their ordered, tightly packed molecular chains but often suffer from brittleness and limited transparency.

Selecting the Right Polymer for Your Application

Selecting the right polymer for your application hinges on understanding the structural differences between amorphous and crystalline polymers. Amorphous polymers offer transparency, flexibility, and impact resistance, making them ideal for applications like optical devices and packaging. Crystalline polymers provide higher chemical resistance, dimensional stability, and tensile strength, which are crucial for engineering parts and high-performance components.

Amorphous Polymer vs Crystalline Polymer Infographic

materialdif.com

materialdif.com