Polyamide 6 offers higher impact resistance and better flexibility compared to Polyamide 66, which excels in thermal stability and mechanical strength. Polyamide 66 has a higher melting point, making it suitable for applications requiring heat resistance, while Polyamide 6 is preferred for faster processing and improved surface finish. Both polymers provide excellent chemical resistance and abrasion durability, but their selection depends on specific performance requirements in automotive, textile, and industrial components.

Table of Comparison

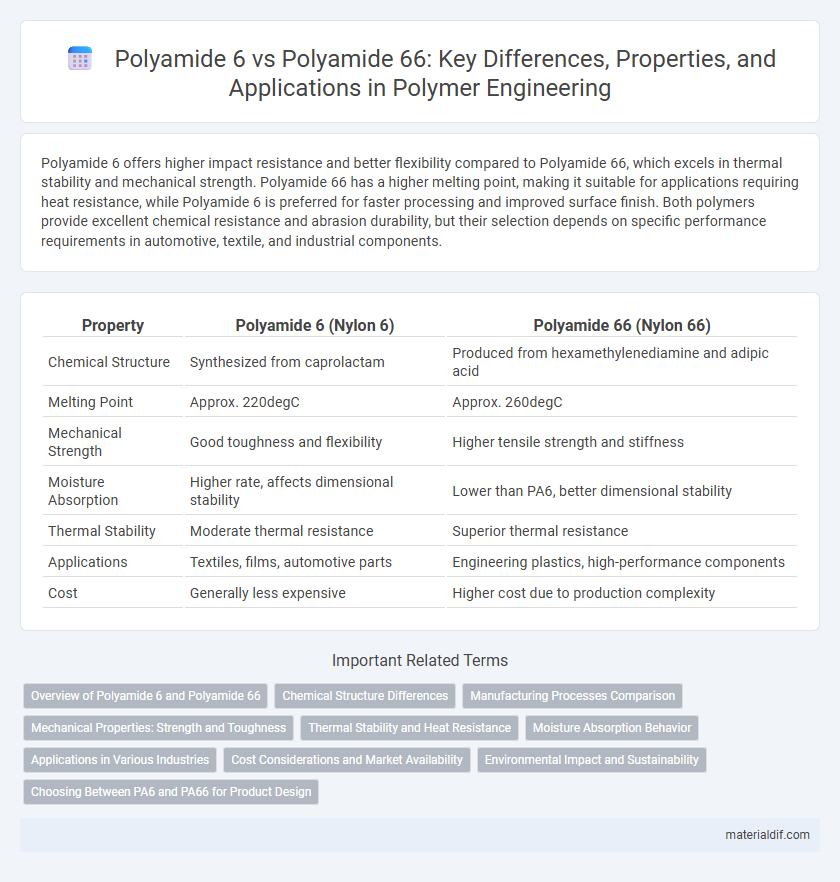

| Property | Polyamide 6 (Nylon 6) | Polyamide 66 (Nylon 66) |

|---|---|---|

| Chemical Structure | Synthesized from caprolactam | Produced from hexamethylenediamine and adipic acid |

| Melting Point | Approx. 220degC | Approx. 260degC |

| Mechanical Strength | Good toughness and flexibility | Higher tensile strength and stiffness |

| Moisture Absorption | Higher rate, affects dimensional stability | Lower than PA6, better dimensional stability |

| Thermal Stability | Moderate thermal resistance | Superior thermal resistance |

| Applications | Textiles, films, automotive parts | Engineering plastics, high-performance components |

| Cost | Generally less expensive | Higher cost due to production complexity |

Overview of Polyamide 6 and Polyamide 66

Polyamide 6, known as Nylon 6, is a synthetic polymer produced via ring-opening polymerization of caprolactam, featuring a repeating unit with six carbon atoms, which offers high toughness and excellent abrasion resistance. Polyamide 66, or Nylon 66, is synthesized through condensation polymerization of hexamethylenediamine and adipic acid, containing twelve carbon atoms per repeating unit, resulting in superior thermal stability and mechanical strength compared to Polyamide 6. Both polymers are widely used in automotive, textile, and industrial applications, with Polyamide 66 preferred for high-temperature environments and Polyamide 6 favored for its easier processing and higher impact resistance.

Chemical Structure Differences

Polyamide 6 consists of a single type of monomer, caprolactam, resulting in a repeating unit with six carbon atoms, whereas polyamide 66 is formed by the polymerization of two different monomers, hexamethylenediamine and adipic acid, each contributing six carbon atoms. This structural difference leads to variations in hydrogen bonding patterns and crystallinity between polyamide 6 and polyamide 66, influencing their mechanical and thermal properties. The simpler chemical structure of polyamide 6 allows for easier processing, while the alternating amide groups in polyamide 66 result in higher melting points and enhanced chemical resistance.

Manufacturing Processes Comparison

Polyamide 6 is produced through the ring-opening polymerization of caprolactam, allowing for continuous polymerization and relatively faster production cycles compared to the condensation polymerization of hexamethylene diamine and adipic acid used in Polyamide 66. The manufacturing of Polyamide 66 involves higher energy consumption due to its step-growth polymerization process, which requires stringent control of reaction conditions to achieve desired molecular weight and crystallinity. Polyamide 6's production process offers greater versatility in molecular weight control and typically results in lower moisture absorption, impacting final material performance and processing efficiency.

Mechanical Properties: Strength and Toughness

Polyamide 6 exhibits high toughness with better impact resistance and flexibility, making it suitable for applications requiring durability under dynamic stress. Polyamide 66 offers superior tensile strength and higher melting temperature, providing enhanced rigidity and heat resistance ideal for structural components. The crystalline structure of Polyamide 66 contributes to its increased hardness, while Polyamide 6's amorphous regions impart greater elongation before breakage.

Thermal Stability and Heat Resistance

Polyamide 6 exhibits lower thermal stability with a melting point around 220degC, while Polyamide 66 has a higher melting point close to 265degC, granting superior heat resistance. The crystalline structure of Polyamide 66 enhances its ability to maintain mechanical properties at elevated temperatures, making it ideal for applications requiring prolonged exposure to heat. Polyamide 6 is more prone to thermal degradation, whereas Polyamide 66 offers greater thermal endurance and dimensional stability under heat stress.

Moisture Absorption Behavior

Polyamide 6 exhibits higher moisture absorption compared to Polyamide 66 due to its molecular structure, which contains more polar amide groups that attract water molecules. This increased moisture uptake leads to significant changes in mechanical properties and dimensional stability for Polyamide 6. Polyamide 66, with its more crystalline structure, offers lower moisture absorption, enhancing its performance in applications requiring reduced water sensitivity.

Applications in Various Industries

Polyamide 6 and Polyamide 66 are extensively used in automotive, electrical, and textile industries due to their excellent mechanical properties and chemical resistance. Polyamide 6 offers superior flexibility and impact strength, making it ideal for components like gears, bearings, and cables, while Polyamide 66 provides higher thermal stability and wear resistance, preferred in engine parts and industrial machinery. Their distinct molecular structures influence specific applications, with Polyamide 6 favored in injection molding and Polyamide 66 commonly used in extrusion and fiber production.

Cost Considerations and Market Availability

Polyamide 6 generally offers lower production costs compared to Polyamide 66 due to simpler polymerization processes and raw material availability, making it more cost-effective for large-scale applications. Polyamide 66 exhibits superior mechanical strength and thermal resistance, commanding a higher price point and niche market segments where performance is critical. Market availability favors Polyamide 6 with broader supply chains and diverse applications, whereas Polyamide 66 is often sourced for specialized industrial uses, impacting overall procurement strategies.

Environmental Impact and Sustainability

Polyamide 6 and Polyamide 66 differ in their environmental impact, with Polyamide 6 generally demonstrating a lower carbon footprint due to its production from caprolactam, which requires less energy compared to the hexamethylene diamine and adipic acid synthesis used for Polyamide 66. Polyamide 6 is also more amenable to mechanical recycling, enhancing its sustainability profile in circular economy applications. However, both polymers face challenges with biodegradability, prompting ongoing research into bio-based alternatives and improved end-of-life management strategies to mitigate environmental concerns.

Choosing Between PA6 and PA66 for Product Design

Polyamide 6 (PA6) offers superior flexibility and processability, making it ideal for intricate, lightweight components, while Polyamide 66 (PA66) provides higher thermal resistance and mechanical strength suited for high-stress applications. PA6 absorbs more moisture, affecting dimensional stability, whereas PA66 maintains better performance in dry and high-temperature environments. Selecting between PA6 and PA66 depends on balancing factors like mechanical properties, thermal stability, moisture absorption, and specific product requirements.

Polyamide 6 vs Polyamide 66 Infographic

materialdif.com

materialdif.com