Biodegradable polymers break down naturally through microbial activity, reducing environmental impact compared to conventional polymers, which persist in ecosystems for decades. These eco-friendly materials are derived from renewable resources and are designed to decompose under specific conditions, minimizing plastic pollution. Conventional polymers, primarily synthesized from fossil fuels, offer durability and cost-effectiveness but contribute significantly to landfill accumulation and marine debris.

Table of Comparison

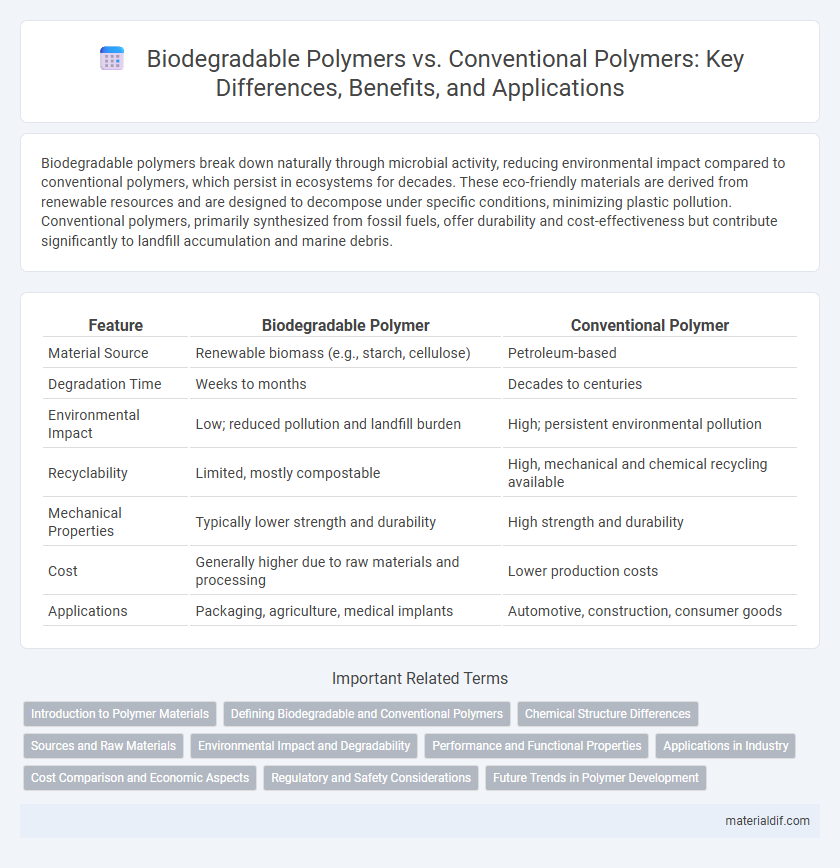

| Feature | Biodegradable Polymer | Conventional Polymer |

|---|---|---|

| Material Source | Renewable biomass (e.g., starch, cellulose) | Petroleum-based |

| Degradation Time | Weeks to months | Decades to centuries |

| Environmental Impact | Low; reduced pollution and landfill burden | High; persistent environmental pollution |

| Recyclability | Limited, mostly compostable | High, mechanical and chemical recycling available |

| Mechanical Properties | Typically lower strength and durability | High strength and durability |

| Cost | Generally higher due to raw materials and processing | Lower production costs |

| Applications | Packaging, agriculture, medical implants | Automotive, construction, consumer goods |

Introduction to Polymer Materials

Biodegradable polymers are designed to break down naturally through microbial activity, reducing environmental impact compared to conventional polymers derived from non-renewable petroleum sources. Conventional polymers such as polyethylene and polypropylene exhibit high durability and resistance to degradation, leading to persistent plastic waste accumulation. Emerging research focuses on balancing performance and sustainability by developing biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) to replace traditional plastics in various applications.

Defining Biodegradable and Conventional Polymers

Biodegradable polymers are materials capable of breaking down into natural substances like water, carbon dioxide, and biomass through microbial activity, promoting environmental sustainability. Conventional polymers, typically derived from petrochemicals, resist degradation and persist in ecosystems for decades, contributing to plastic pollution. The primary distinction lies in the chemical structure and enzymatic digestibility, which determines the polymers' environmental impact and end-of-life disposal options.

Chemical Structure Differences

Biodegradable polymers typically contain hydrolyzable functional groups such as esters, amides, or anhydrides within their chemical structure, enabling enzymatic or hydrolytic breakdown under environmental conditions. In contrast, conventional polymers like polyethylene and polystyrene consist of long carbon-carbon chains with strong C-C bonds that resist degradation due to their non-polar, inert hydrocarbon backbones. The presence of labile bonds and polar groups in biodegradable polymers facilitates microbial attack, leading to their environmentally friendly decomposition compared to the persistent nature of conventional polymers.

Sources and Raw Materials

Biodegradable polymers primarily derive from renewable resources such as starch, cellulose, and polylactic acid obtained from corn, sugarcane, or potato, contrasting with conventional polymers sourced from non-renewable fossil fuels like petroleum and natural gas. The raw materials for biodegradable polymers promote sustainability through reduced carbon footprint and enhanced environmental compatibility, while conventional polymers rely heavily on petrochemical processes contributing to pollution and resource depletion. Innovations in bio-based feedstocks and green chemistry are advancing the development of biodegradable polymers as eco-friendly alternatives to traditional plastic materials.

Environmental Impact and Degradability

Biodegradable polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), break down naturally through microbial activity, significantly reducing plastic waste accumulation and environmental pollution compared to conventional polymers like polyethylene (PE) and polypropylene (PP). Conventional polymers persist in ecosystems for hundreds of years, contributing to microplastic pollution and harming wildlife, whereas biodegradable polymers degrade into non-toxic byproducts under composting or soil conditions within months. The shift towards biodegradable polymers supports sustainable waste management practices and mitigates long-term ecological damage by minimizing landfill volume and ocean contamination.

Performance and Functional Properties

Biodegradable polymers exhibit enhanced environmental compatibility through natural decomposition, yet they often show lower mechanical strength and thermal stability compared to conventional polymers like polyethylene or polypropylene. Conventional polymers provide superior durability, chemical resistance, and consistent performance in high-stress applications, making them ideal for long-term use. Advances in biodegradable polymer composites and additives aim to improve their tensile strength, barrier properties, and thermal resistance to narrow the performance gap with traditional polymers.

Applications in Industry

Biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are increasingly utilized in packaging, agriculture, and biomedical industries due to their eco-friendly degradation properties. Conventional polymers such as polyethylene (PE) and polypropylene (PP) dominate automotive, construction, and electronics sectors because of their durability and cost-effectiveness. Industry trends reveal a shift towards biodegradable polymers in single-use products to reduce environmental impact while conventional polymers continue to support heavy-duty applications requiring long-term stability.

Cost Comparison and Economic Aspects

Biodegradable polymers generally have higher production costs than conventional polymers due to more expensive raw materials and complex manufacturing processes. Despite initial costs, biodegradable polymers can reduce long-term environmental cleanup expenses and waste management fees, offering potential economic benefits for sustainable industries. Market demand and regulatory incentives increasingly influence the cost-effectiveness of biodegradable polymers compared to traditional plastics.

Regulatory and Safety Considerations

Biodegradable polymers are subject to stringent regulatory frameworks emphasizing environmental impact, biodegradation rates, and toxicity to ensure safe disposal and reduce ecological harm. Conventional polymers face increasing regulatory scrutiny due to their persistence, potential for microplastic pollution, and challenges in recycling processes. Safety standards for biodegradable polymers often mandate comprehensive testing for biocompatibility, degradation byproducts, and compliance with international environmental directives such as REACH and EPA guidelines.

Future Trends in Polymer Development

Biodegradable polymers are gaining significant traction due to increasing environmental regulations and consumer demand for sustainable materials, driving innovation in bio-based monomers and enzyme-mediated degradation techniques. Future trends in polymer development emphasize enhancing mechanical properties and processing efficiency of biodegradable polymers to match those of conventional polymers like polyethylene and polypropylene. Advances in nanocomposites and additive manufacturing are expected to further expand the application scope of biodegradable polymers, positioning them as viable alternatives in packaging, agriculture, and medical devices.

Biodegradable Polymer vs Conventional Polymer Infographic

materialdif.com

materialdif.com