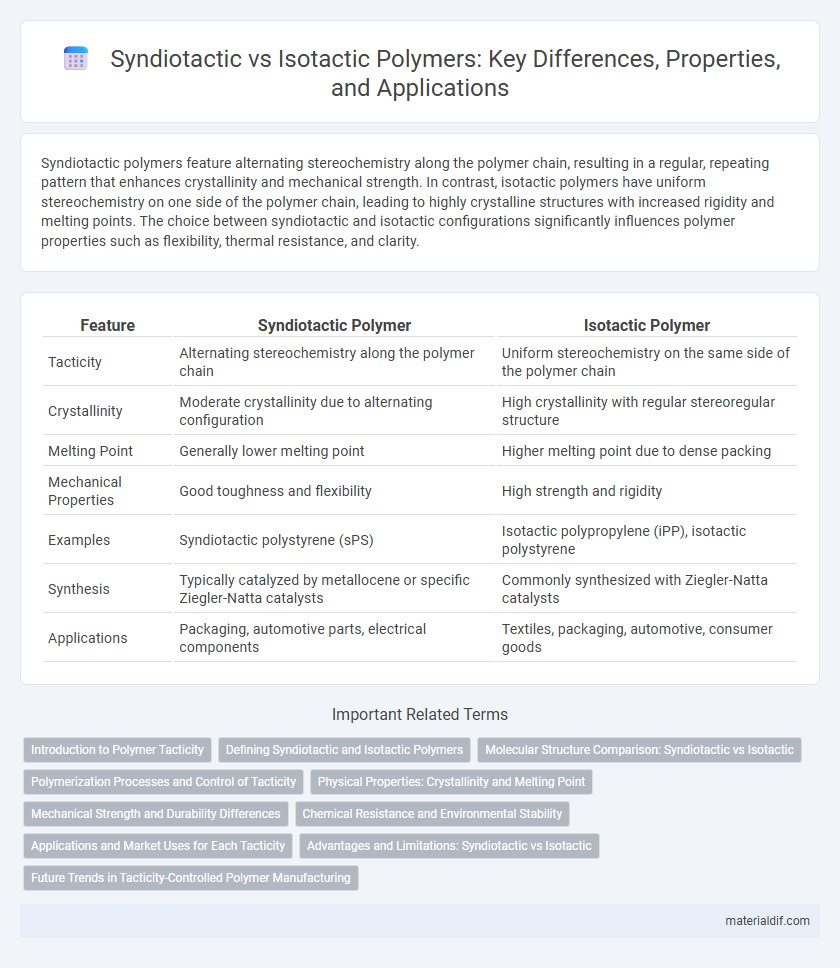

Syndiotactic polymers feature alternating stereochemistry along the polymer chain, resulting in a regular, repeating pattern that enhances crystallinity and mechanical strength. In contrast, isotactic polymers have uniform stereochemistry on one side of the polymer chain, leading to highly crystalline structures with increased rigidity and melting points. The choice between syndiotactic and isotactic configurations significantly influences polymer properties such as flexibility, thermal resistance, and clarity.

Table of Comparison

| Feature | Syndiotactic Polymer | Isotactic Polymer |

|---|---|---|

| Tacticity | Alternating stereochemistry along the polymer chain | Uniform stereochemistry on the same side of the polymer chain |

| Crystallinity | Moderate crystallinity due to alternating configuration | High crystallinity with regular stereoregular structure |

| Melting Point | Generally lower melting point | Higher melting point due to dense packing |

| Mechanical Properties | Good toughness and flexibility | High strength and rigidity |

| Examples | Syndiotactic polystyrene (sPS) | Isotactic polypropylene (iPP), isotactic polystyrene |

| Synthesis | Typically catalyzed by metallocene or specific Ziegler-Natta catalysts | Commonly synthesized with Ziegler-Natta catalysts |

| Applications | Packaging, automotive parts, electrical components | Textiles, packaging, automotive, consumer goods |

Introduction to Polymer Tacticity

Polymer tacticity refers to the stereoregularity of the arrangement of side groups along the polymer chain, critically influencing material properties. Syndiotactic polymers feature alternating stereochemistry of side groups, enhancing crystallinity and mechanical strength. Isotactic polymers possess side groups aligned on the same side, promoting high crystallinity and melting points, essential for applications requiring rigidity and thermal resistance.

Defining Syndiotactic and Isotactic Polymers

Syndiotactic polymers feature alternating substituent groups on opposite sides of the polymer backbone, creating a regular pattern that influences crystallinity and mechanical properties. Isotactic polymers have all substituent groups positioned on the same side of the polymer chain, resulting in higher crystallinity and melting points. These tacticity variations significantly affect polymer behavior, including solubility and thermal resistance.

Molecular Structure Comparison: Syndiotactic vs Isotactic

Syndiotactic polymers feature alternating stereochemistry along the polymer chain, resulting in a zigzag pattern of side groups that enhance crystallinity and mechanical strength. In contrast, isotactic polymers have side groups aligned on the same side, producing a more uniform, tightly packed molecular structure that often leads to higher melting points and rigidity. These stereochemical arrangements critically influence polymer properties such as thermal stability, solubility, and tensile behavior.

Polymerization Processes and Control of Tacticity

Syndiotactic and isotactic polymers differ in the spatial arrangement of their substituent groups along the polymer chain, significantly influencing their physical properties. Polymerization processes such as metallocene or Ziegler-Natta catalysis offer precise control over tacticity by regulating the stereochemistry of monomer insertion. Advanced catalyst design enables selective syndiotactic or isotactic polymer production, optimizing crystallinity, melting temperature, and mechanical strength in applications like polypropylene and polystyrene.

Physical Properties: Crystallinity and Melting Point

Syndiotactic polymers exhibit higher crystallinity due to the regular alternating arrangement of side groups, resulting in enhanced packing efficiency and thermal stability. Isotactic polymers, characterized by identical side group orientation, also demonstrate high crystallinity but often have a higher melting point compared to syndiotactic polymers because of more uniform chain alignment. These structural differences critically influence their melting temperature, mechanical strength, and chemical resistance in applications such as packaging and automotive components.

Mechanical Strength and Durability Differences

Syndiotactic polymers exhibit enhanced mechanical strength and durability due to their alternating stereochemistry, which promotes better chain packing and crystallinity compared to isotactic polymers. Isotactic polymers, characterized by uniform stereochemistry, tend to form highly regular and dense crystalline structures, resulting in superior tensile strength but often reduced impact resistance. The choice between syndiotactic and isotactic arrangements directly influences polymer performance in applications demanding a balance of toughness and long-term stability.

Chemical Resistance and Environmental Stability

Syndiotactic polymers exhibit enhanced chemical resistance due to their alternating side group arrangement, which creates a more irregular and less dense crystalline structure that resists solvent penetration. Isotactic polymers display higher environmental stability with their uniform side group orientation, leading to tightly packed crystals that provide superior resistance to UV degradation and thermal oxidation. Both tacticities influence the durability of polymers in harsh chemical environments, but isotactic configurations generally offer better protection against environmental stressors while syndiotactic structures excel in resisting aggressive solvents.

Applications and Market Uses for Each Tacticity

Syndiotactic polymers exhibit higher flexibility and impact resistance, making them ideal for applications in automotive parts and flexible packaging materials. Isotactic polymers offer superior crystallinity and mechanical strength, commonly used in rigid containers, pipes, and fibers. The market favors syndiotactic variants for products requiring elasticity and transparency, while isotactic polymers dominate in structural applications demanding durability and heat resistance.

Advantages and Limitations: Syndiotactic vs Isotactic

Syndiotactic polymers exhibit advantages in improved impact resistance and greater flexibility due to their alternating stereochemistry, enhancing toughness in applications such as packaging and automotive parts. Isotactic polymers offer superior crystallinity and higher melting points, resulting in better mechanical strength and thermal stability ideal for structural and high-performance uses. Limitations of syndiotactic polymers include lower crystallinity and thermal resistance compared to isotactic variants, while isotactic polymers can be more brittle and less impact-resistant under certain conditions.

Future Trends in Tacticity-Controlled Polymer Manufacturing

Advancements in tacticity-controlled polymer manufacturing emphasize syndiotactic and isotactic configurations to tailor material properties for high-performance applications such as biodegradable plastics and smart textiles. Emerging catalyst technologies and precision polymerization techniques enable enhanced control over stereoregularity, improving mechanical strength and thermal stability. Future trends prioritize sustainable synthesis with reduced environmental impact while maintaining scalability for industrial production.

Syndiotactic vs Isotactic Infographic

materialdif.com

materialdif.com