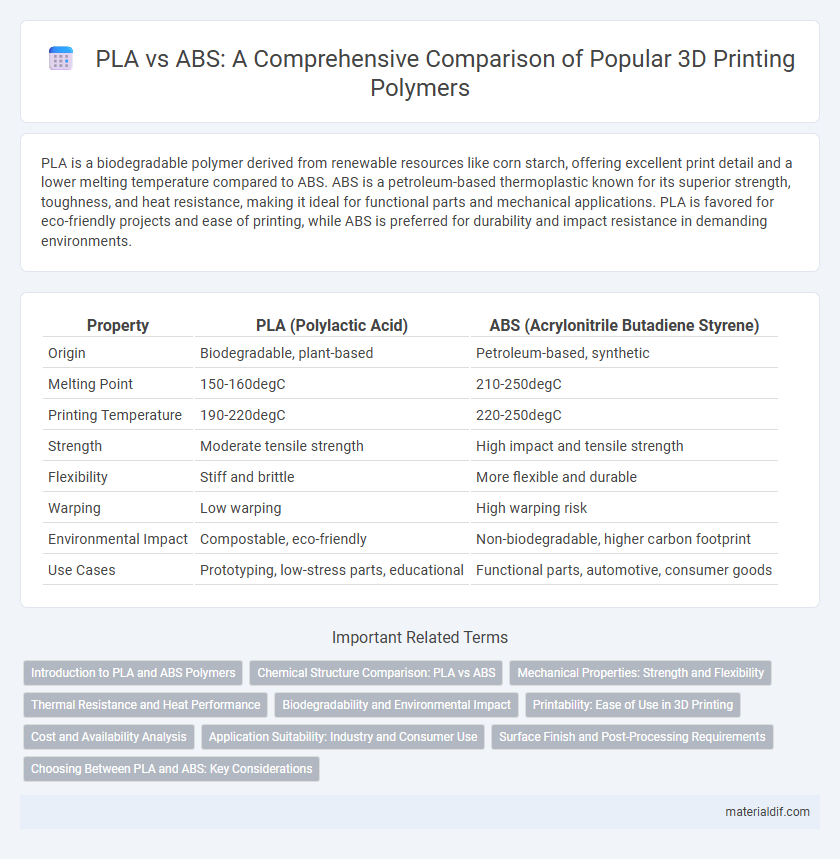

PLA is a biodegradable polymer derived from renewable resources like corn starch, offering excellent print detail and a lower melting temperature compared to ABS. ABS is a petroleum-based thermoplastic known for its superior strength, toughness, and heat resistance, making it ideal for functional parts and mechanical applications. PLA is favored for eco-friendly projects and ease of printing, while ABS is preferred for durability and impact resistance in demanding environments.

Table of Comparison

| Property | PLA (Polylactic Acid) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

| Origin | Biodegradable, plant-based | Petroleum-based, synthetic |

| Melting Point | 150-160degC | 210-250degC |

| Printing Temperature | 190-220degC | 220-250degC |

| Strength | Moderate tensile strength | High impact and tensile strength |

| Flexibility | Stiff and brittle | More flexible and durable |

| Warping | Low warping | High warping risk |

| Environmental Impact | Compostable, eco-friendly | Non-biodegradable, higher carbon footprint |

| Use Cases | Prototyping, low-stress parts, educational | Functional parts, automotive, consumer goods |

Introduction to PLA and ABS Polymers

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane, known for its environmentally friendly properties and ease of use in 3D printing. ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based thermoplastic recognized for its toughness, impact resistance, and high melting point, making it suitable for durable and heat-resistant applications. Both polymers serve distinct purposes in manufacturing and prototyping, with PLA favored for eco-conscious products and ABS chosen for strength and thermal stability.

Chemical Structure Comparison: PLA vs ABS

PLA (Polylactic Acid) is a biodegradable thermoplastic polyester derived from renewable resources like corn starch, featuring a linear aliphatic structure with ester linkages that contribute to its biodegradability. ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based copolymer consisting of acrylonitrile, butadiene, and styrene units, arranged in a block structure that enhances impact resistance and toughness. The chemical difference between PLA's ester-based backbone and ABS's styrene-butadiene-acrylonitrile architecture directly affects their mechanical properties, thermal stability, and environmental impact.

Mechanical Properties: Strength and Flexibility

PLA exhibits higher tensile strength but lower impact resistance compared to ABS, making it more rigid but brittle under stress. ABS demonstrates superior flexibility and toughness, allowing it to withstand greater deformation without cracking. These mechanical properties influence the choice of polymer based on the application's durability and load-bearing requirements.

Thermal Resistance and Heat Performance

Polylactic Acid (PLA) offers lower thermal resistance with a heat deflection temperature typically around 60degC, making it less suitable for high-temperature applications. Acrylonitrile Butadiene Styrene (ABS) boasts superior heat performance, with a heat deflection temperature near 100degC, providing enhanced durability under thermal stress. This makes ABS the preferred choice for parts exposed to elevated temperatures or requiring higher structural integrity.

Biodegradability and Environmental Impact

PLA (Polylactic Acid) is a biodegradable polymer derived from renewable resources like corn starch, resulting in a lower environmental impact compared to ABS (Acrylonitrile Butadiene Styrene), which is petroleum-based and non-biodegradable. PLA decomposes under industrial composting conditions within 6 months, significantly reducing landfill accumulation and pollution. In contrast, ABS can persist for decades, contributing to microplastic pollution and higher carbon emissions during production and disposal.

Printability: Ease of Use in 3D Printing

PLA offers superior printability due to its low warping tendency and compatibility with most 3D printers, making it ideal for beginners and detailed models. ABS requires higher printing temperatures and a heated bed to prevent warping and cracking, posing challenges for novice users. The ease of use with PLA reduces post-processing effort and improves print success rates in desktop 3D printing.

Cost and Availability Analysis

PLA is generally more cost-effective than ABS due to lower raw material prices and simpler processing requirements, making it a preferred choice for budget-conscious applications. Availability of PLA is widespread in consumer-grade 3D printing filaments, driven by its renewable resource base and growing market demand. ABS, though slightly more expensive, remains readily available with extensive industrial and automotive supply chains supporting its distribution and procurement.

Application Suitability: Industry and Consumer Use

PLA is widely favored in consumer applications such as 3D printing and packaging due to its biodegradability and ease of use, while ABS is preferred in industrial settings for its superior strength, impact resistance, and thermal stability. PLA's low melting point and environmental friendliness make it ideal for disposable products and prototyping, whereas ABS's durability supports automotive components, electronics housings, and functional parts requiring mechanical toughness. Selection between PLA and ABS depends on balancing environmental impact with performance requirements in specific industry and consumer contexts.

Surface Finish and Post-Processing Requirements

PLA offers a smoother surface finish directly off the printer, making it ideal for detailed models that require minimal post-processing. ABS, while more durable and heat-resistant, often exhibits a rougher texture necessitating sanding, acetone vapor smoothing, or other post-processing techniques to achieve a polished look. Surface finishing for PLA is generally simpler and less time-consuming compared to the extensive work needed to refine ABS prints.

Choosing Between PLA and ABS: Key Considerations

Choose PLA for biodegradable, eco-friendly 3D printing applications, especially in low-temperature environments, due to its easy printing and minimal warping properties. Opt for ABS when requiring greater durability, heat resistance up to 105degC, and impact strength, ideal for functional prototypes and industrial parts. Consider factors like print bed temperature, environmental impact, and mechanical requirements to determine the best polymer for your project.

PLA vs ABS Infographic

materialdif.com

materialdif.com