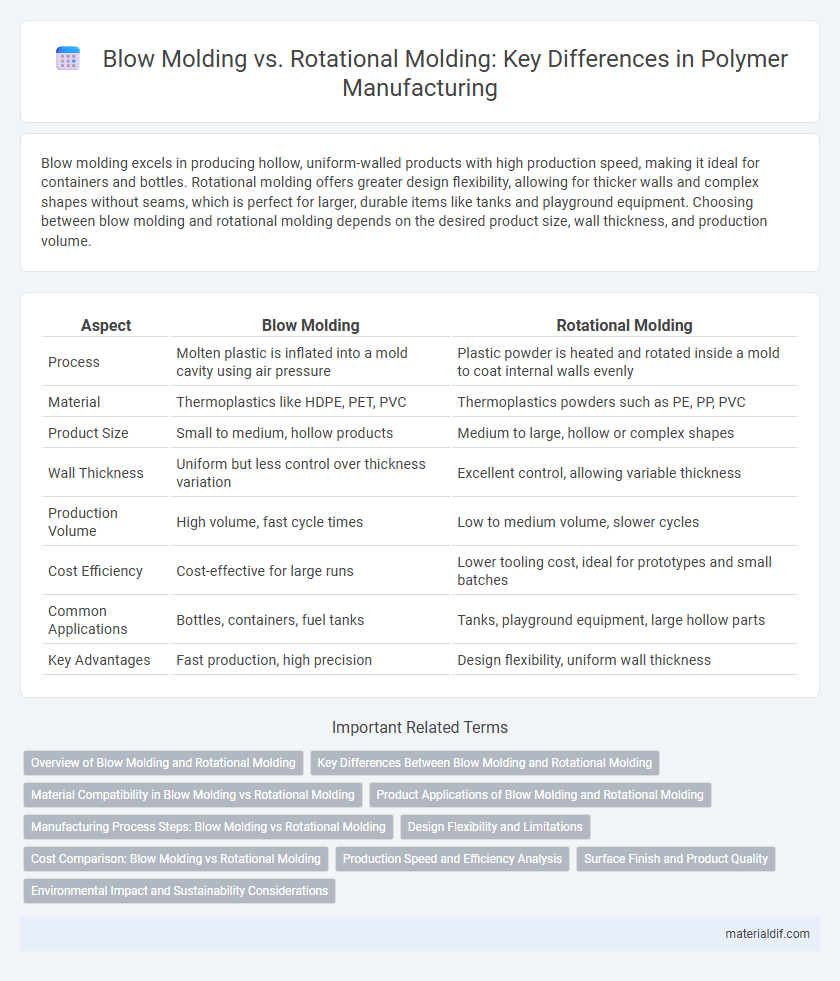

Blow molding excels in producing hollow, uniform-walled products with high production speed, making it ideal for containers and bottles. Rotational molding offers greater design flexibility, allowing for thicker walls and complex shapes without seams, which is perfect for larger, durable items like tanks and playground equipment. Choosing between blow molding and rotational molding depends on the desired product size, wall thickness, and production volume.

Table of Comparison

| Aspect | Blow Molding | Rotational Molding |

|---|---|---|

| Process | Molten plastic is inflated into a mold cavity using air pressure | Plastic powder is heated and rotated inside a mold to coat internal walls evenly |

| Material | Thermoplastics like HDPE, PET, PVC | Thermoplastics powders such as PE, PP, PVC |

| Product Size | Small to medium, hollow products | Medium to large, hollow or complex shapes |

| Wall Thickness | Uniform but less control over thickness variation | Excellent control, allowing variable thickness |

| Production Volume | High volume, fast cycle times | Low to medium volume, slower cycles |

| Cost Efficiency | Cost-effective for large runs | Lower tooling cost, ideal for prototypes and small batches |

| Common Applications | Bottles, containers, fuel tanks | Tanks, playground equipment, large hollow parts |

| Key Advantages | Fast production, high precision | Design flexibility, uniform wall thickness |

Overview of Blow Molding and Rotational Molding

Blow molding shapes hollow plastic products by inflating a heated thermoplastic parison inside a mold cavity, commonly used for containers like bottles and tanks. Rotational molding rotates a heated mold filled with polymer powder along two perpendicular axes, evenly distributing and fusing the material to create large, hollow, and seamless items such as storage tanks and kayaks. Both processes offer unique advantages in manufacturing hollow polymer products with differing material efficiency, design flexibility, and production cost.

Key Differences Between Blow Molding and Rotational Molding

Blow molding produces hollow objects by inflating heated plastic into a mold, ideal for high-volume production of containers like bottles. Rotational molding involves heating powder resin inside a rotating mold to create large, seamless, and complex hollow parts with uniform wall thickness. Key differences include blow molding's faster cycle times and thinner walls versus rotational molding's flexibility in shape and size with lower tooling costs.

Material Compatibility in Blow Molding vs Rotational Molding

Blow molding primarily supports thermoplastic materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) due to their ability to soften and stretch uniformly under heat and pressure. Rotational molding accommodates a broader range of polymers, including polyethylene, nylon, and certain polyurethane blends, because the process involves heating resin powder evenly within a mold, allowing for complex shapes without stress on the material. Material compatibility in blow molding is generally constrained by the need for high melt strength and flexibility, whereas rotational molding offers greater versatility in polymer types and filler incorporation for enhanced mechanical properties.

Product Applications of Blow Molding and Rotational Molding

Blow molding is predominantly used for manufacturing hollow plastic products such as bottles, containers, and automotive fuel tanks due to its efficiency in producing uniform, lightweight, and high-volume items. Rotational molding excels in creating large, hollow, and complex shapes like storage tanks, kayaks, and playground equipment, favored for its ability to produce stress-free, durable parts with consistent wall thickness. Both molding techniques serve distinct product applications, with blow molding suited for high precision and rapid production, while rotational molding supports versatility and cost-effective fabrication of large components.

Manufacturing Process Steps: Blow Molding vs Rotational Molding

Blow molding involves melting plastic resin and extruding it into a hollow tube called a parison, which is then clamped into a mold and inflated with air to take the mold's shape. Rotational molding starts with placing powdered polymer resin into a mold that rotates biaxially inside an oven, allowing the material to evenly coat the interior surface and fuse into a hollow part as it cools. While blow molding is faster and suited for high-volume production, rotational molding offers greater design flexibility and produces stress-free, uniform wall thickness in complex shapes.

Design Flexibility and Limitations

Blow molding offers excellent design flexibility for creating hollow, lightweight parts with uniform wall thickness, ideal for bottles and containers but struggles with intricate shapes and variable wall thickness. Rotational molding excels in producing large, complex parts with consistent wall thickness and allows for easy incorporation of multiple colors or materials, though it has longer cycle times and less precision in tight tolerances. Both processes have unique limitations impacting the complexity and detail achievable in polymer product design.

Cost Comparison: Blow Molding vs Rotational Molding

Blow molding typically incurs higher upfront tooling costs but offers lower per-unit expenses for large production runs, making it cost-effective for mass manufacturing of hollow polymer products. Rotational molding involves lower initial tooling investment and greater flexibility with smaller batches, but higher labor and cycle times result in increased per-unit costs compared to blow molding. The choice between blow molding and rotational molding depends on production volume, with blow molding favored for high-volume output due to economies of scale, while rotational molding suits complex shapes and smaller quantities with moderate cost efficiency.

Production Speed and Efficiency Analysis

Blow molding offers significantly faster production speeds compared to rotational molding, with cycle times often measured in seconds, making it ideal for high-volume manufacturing of hollow polymer products. Rotational molding, while slower due to longer heating and cooling cycles, excels in producing large, complex shapes with uniform wall thickness and minimal material waste. Efficiency in blow molding is driven by automation and rapid cavity filling, whereas rotational molding prioritizes flexibility and low tooling costs despite its extended cycle times.

Surface Finish and Product Quality

Blow molding produces smooth, uniform surface finishes ideal for bottles and containers requiring high clarity and minimal defects. Rotational molding often results in textured surfaces with slight variations, suitable for large, hollow products where impact resistance and durability are prioritized over smoothness. Surface quality in blow molding typically outperforms rotational molding due to controlled material distribution and cooling processes.

Environmental Impact and Sustainability Considerations

Blow molding generates less material waste due to its precision in forming hollow parts, making it more resource-efficient compared to rotational molding, which often results in excess polymer scrap from trimming. Rotational molding consumes lower energy per cycle but typically uses thermoplastics that are more challenging to recycle, while blow molding favors thermoplastics like PET and HDPE that have higher recycling rates. Choosing blow molding can enhance sustainability by optimizing material use and supporting circular economy goals through easier recycling pathways.

Blow Molding vs Rotational Molding Infographic

materialdif.com

materialdif.com