Nylon 6 and Nylon 6,6 are both synthetic polyamides widely used in textiles and engineering plastics, but they differ in molecular structure and properties. Nylon 6 is derived from caprolactam, while Nylon 6,6 is synthesized from hexamethylene diamine and adipic acid, giving it higher melting temperature and superior mechanical strength. These differences make Nylon 6,6 more suitable for high-performance applications requiring greater heat resistance and durability.

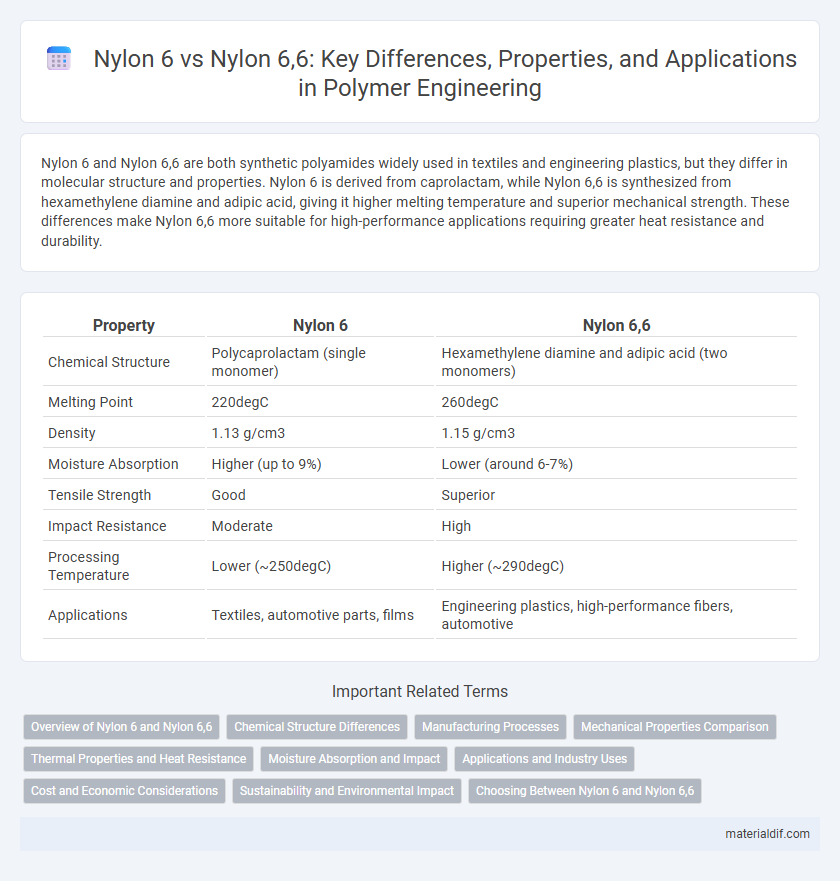

Table of Comparison

| Property | Nylon 6 | Nylon 6,6 |

|---|---|---|

| Chemical Structure | Polycaprolactam (single monomer) | Hexamethylene diamine and adipic acid (two monomers) |

| Melting Point | 220degC | 260degC |

| Density | 1.13 g/cm3 | 1.15 g/cm3 |

| Moisture Absorption | Higher (up to 9%) | Lower (around 6-7%) |

| Tensile Strength | Good | Superior |

| Impact Resistance | Moderate | High |

| Processing Temperature | Lower (~250degC) | Higher (~290degC) |

| Applications | Textiles, automotive parts, films | Engineering plastics, high-performance fibers, automotive |

Overview of Nylon 6 and Nylon 6,6

Nylon 6 is a synthetic polymer made from caprolactam through ring-opening polymerization, offering excellent elasticity and abrasion resistance. Nylon 6,6 is synthesized from hexamethylene diamine and adipic acid, resulting in higher melting point and greater tensile strength compared to Nylon 6. Both types are widely used in fibers, plastics, and engineering applications, but Nylon 6,6 exhibits superior thermal stability and mechanical properties.

Chemical Structure Differences

Nylon 6 is synthesized from caprolactam, featuring a repeating unit with a single amide linkage derived from a six-carbon monomer, resulting in a polymer with a distinct epsilon-caprolactam ring opening structure. Nylon 6,6 is produced from hexamethylene diamine and adipic acid, characterized by alternating diamine and diacid units forming a polymer with two amide linkages per repeating unit and a more symmetrical, linear chain. These chemical structure differences influence crystallinity, melting points, and mechanical properties between Nylon 6 and Nylon 6,6.

Manufacturing Processes

Nylon 6 is produced via ring-opening polymerization of caprolactam, which offers a simpler and faster manufacturing process compared to Nylon 6,6, synthesized through condensation polymerization of hexamethylenediamine and adipic acid. The continuous polymerization of Nylon 6 allows for better control of molecular weight and consistent product quality, whereas Nylon 6,6 manufacturing requires precise stoichiometric balance to avoid defects. Industrial production of Nylon 6 typically involves fewer purification steps, reducing energy consumption compared to the more complex and multi-step process for Nylon 6,6.

Mechanical Properties Comparison

Nylon 6 exhibits lower tensile strength and impact resistance compared to Nylon 6,6, which has a higher melting point and superior mechanical durability due to its crystalline structure. Nylon 6,6 typically provides enhanced stiffness and better resistance to wear and fatigue, making it ideal for high-stress applications. The molecular arrangement in Nylon 6,6 contributes to improved dimensional stability and higher modulus values relative to Nylon 6.

Thermal Properties and Heat Resistance

Nylon 6,6 exhibits higher melting temperature around 265degC compared to Nylon 6 which melts near 220degC, making Nylon 6,6 preferable for applications requiring superior heat resistance. The thermal stability of Nylon 6,6 enables it to maintain mechanical integrity under prolonged exposure to elevated temperatures, whereas Nylon 6 tends to degrade more rapidly. Heat aging tests confirm Nylon 6,6's enhanced performance in resisting thermal oxidation, critical for high-temperature environments in automotive and industrial sectors.

Moisture Absorption and Impact

Nylon 6 absorbs more moisture compared to Nylon 6,6, resulting in greater dimensional changes and reduced mechanical properties under humid conditions. In terms of impact resistance, Nylon 6 exhibits higher toughness and better energy absorption, making it more suitable for applications requiring enhanced durability. Nylon 6,6, while more rigid and heat-resistant, tends to have lower impact strength and less moisture absorption, affecting its performance in moist environments.

Applications and Industry Uses

Nylon 6 offers excellent elasticity and impact resistance, making it preferred in textile fibers, packaging films, and automotive parts requiring flexibility. Nylon 6,6 features higher melting point and tensile strength, ideal for demanding applications like industrial machinery components, electrical connectors, and high-performance automotive under-hood parts. Both polymers serve extensively in apparel and industrial sectors, but Nylon 6,6 dominates where superior mechanical and thermal properties are critical.

Cost and Economic Considerations

Nylon 6 typically offers lower production costs compared to Nylon 6,6 due to its simpler polymerization process and fewer raw material requirements, making it more economical for large-scale manufacturing. Nylon 6,6 demands higher energy input and more expensive hexamethylene diamine and adipic acid feedstocks, contributing to increased material costs. Manufacturers often choose Nylon 6 for cost-sensitive applications, while Nylon 6,6 is preferred when higher thermal and mechanical performance justifies the premium price.

Sustainability and Environmental Impact

Nylon 6 and Nylon 6,6 differ significantly in their sustainability profiles, with Nylon 6 being more energy-efficient to produce due to its single monomer polymerization from caprolactam, resulting in lower greenhouse gas emissions compared to Nylon 6,6, which requires hexamethylenediamine and adipic acid. Nylon 6 also offers better recyclability through mechanical and chemical recycling processes, contributing to reduced environmental pollution and resource conservation. Despite Nylon 6,6's superior mechanical properties, Nylon 6's lower carbon footprint and enhanced circular economy potential make it a more environmentally favorable choice in textile and engineering applications.

Choosing Between Nylon 6 and Nylon 6,6

Nylon 6 offers higher impact resistance and better elasticity, making it ideal for applications requiring toughness and flexibility, while Nylon 6,6 provides superior heat resistance, strength, and chemical stability suited for high-performance engineering components. The choice depends on operating temperature ranges, mechanical load demands, and environmental exposure, with Nylon 6 favored for automotive parts and Nylon 6,6 preferred in electrical and industrial uses. Cost differences also influence selection, as Nylon 6 is generally more economical but Nylon 6,6 delivers enhanced durability under extreme conditions.

Nylon 6 vs Nylon 6,6 Infographic

materialdif.com

materialdif.com