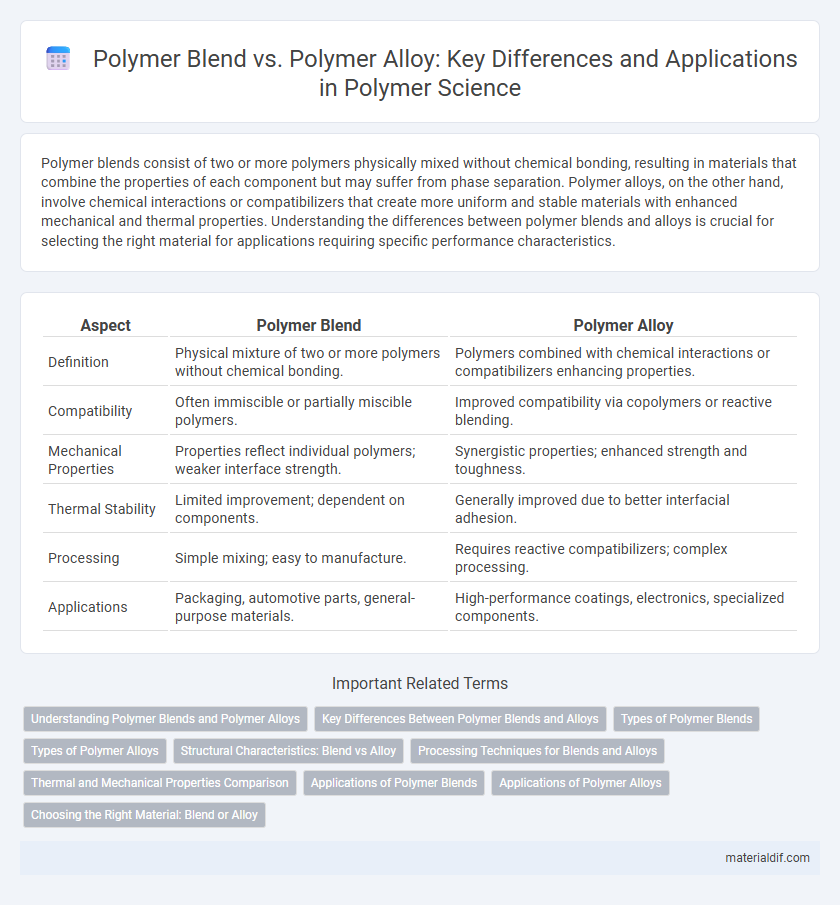

Polymer blends consist of two or more polymers physically mixed without chemical bonding, resulting in materials that combine the properties of each component but may suffer from phase separation. Polymer alloys, on the other hand, involve chemical interactions or compatibilizers that create more uniform and stable materials with enhanced mechanical and thermal properties. Understanding the differences between polymer blends and alloys is crucial for selecting the right material for applications requiring specific performance characteristics.

Table of Comparison

| Aspect | Polymer Blend | Polymer Alloy |

|---|---|---|

| Definition | Physical mixture of two or more polymers without chemical bonding. | Polymers combined with chemical interactions or compatibilizers enhancing properties. |

| Compatibility | Often immiscible or partially miscible polymers. | Improved compatibility via copolymers or reactive blending. |

| Mechanical Properties | Properties reflect individual polymers; weaker interface strength. | Synergistic properties; enhanced strength and toughness. |

| Thermal Stability | Limited improvement; dependent on components. | Generally improved due to better interfacial adhesion. |

| Processing | Simple mixing; easy to manufacture. | Requires reactive compatibilizers; complex processing. |

| Applications | Packaging, automotive parts, general-purpose materials. | High-performance coatings, electronics, specialized components. |

Understanding Polymer Blends and Polymer Alloys

Polymer blends consist of two or more polymers physically mixed without chemical bonding, offering combined properties while maintaining individual polymer characteristics. Polymer alloys involve chemical interactions or compatibilizers that improve phase adhesion, resulting in materials with enhanced mechanical strength and durability. Understanding the differences between them is crucial for tailoring materials in applications such as automotive, packaging, and electronics.

Key Differences Between Polymer Blends and Alloys

Polymer blends consist of two or more polymers physically mixed without chemical bonding, resulting in materials with combined properties but often phase separation. Polymer alloys involve chemical or physical interactions leading to a more uniform material with enhanced compatibility and mechanical properties. Key differences include blend heterogeneity versus alloy homogeneity, compatibility levels, and variations in thermal and mechanical stability.

Types of Polymer Blends

Polymer blends consist of physically mixed polymers that retain their distinct phases, with types including miscible, immiscible, and compatible blends, where miscible blends form a single homogeneous phase. Immiscible blends exhibit phase separation but can be stabilized with compatibilizers to improve interfacial adhesion. Compatible blends, often enhanced by additives, show partially miscible behavior, resulting in improved mechanical and thermal properties compared to pure polymers.

Types of Polymer Alloys

Polymer alloys are multiphase materials composed of two or more polymers combined at the molecular level, resulting in enhanced mechanical and thermal properties compared to polymer blends, which are simply physical mixtures without chemical bonding. Common types of polymer alloys include thermoplastic alloys such as alloyed polyolefins, polycarbonate alloys, and engineering polymer alloys like polyamide-polyether blends, each tailored for specific applications requiring improved toughness, chemical resistance, or heat stability. These alloys exhibit improved interfacial adhesion and phase compatibility due to grafting or reactive compatibilization techniques, distinguishing them from basic polymer blends.

Structural Characteristics: Blend vs Alloy

Polymer blends consist of two or more polymers physically mixed without chemical bonding, resulting in phase-separated morphologies with distinct domains. Polymer alloys exhibit chemical interactions or compatibilization between components, creating a more homogeneous microstructure with improved interfacial adhesion. The structural characteristics of blends lead to distinct phase boundaries, while alloys display enhanced compatibility and uniformity at the molecular level.

Processing Techniques for Blends and Alloys

Polymer blends are typically processed through conventional techniques such as melt blending, solution blending, and mechanical mixing, allowing for easier dispersion and compatibility control. Polymer alloys often require more specialized approaches like reactive extrusion or in-situ compatibilization to achieve enhanced interfacial adhesion and phase morphology. Processing parameters such as temperature, shear rate, and mixing time critically influence the final properties of both polymer blends and alloys.

Thermal and Mechanical Properties Comparison

Polymer blends typically exhibit phase-separated morphologies resulting in variable thermal stability and mechanical strength depending on the compatibility of constituent polymers. Polymer alloys, formed through reactive compatibilization or copolymerization, demonstrate improved thermal resistance and enhanced mechanical properties such as tensile strength and impact toughness due to better phase integration. Thermal properties of polymer alloys often show higher glass transition temperatures (Tg) and melting points compared to polymer blends, while mechanical performance benefits from reduced phase separation and enhanced interfacial adhesion.

Applications of Polymer Blends

Polymer blends are widely used in packaging, automotive parts, and consumer goods due to their cost-effectiveness and tailored properties like improved toughness and chemical resistance. Unlike polymer alloys, which involve chemical bonding for enhanced performance, blends rely on physical mixing to combine characteristics from different polymers, making them ideal for flexible customization. Common applications include food packaging films, automotive interiors, and electronic device housings where specific mechanical and thermal properties are critical.

Applications of Polymer Alloys

Polymer alloys are widely used in automotive parts, offering enhanced mechanical strength and thermal stability compared to conventional polymer blends, which improves durability and safety. These materials also find applications in electronics for manufacturing connectors and housings, where high impact resistance and dimensional stability are crucial. In packaging, polymer alloys provide superior barrier properties and processability, optimizing the shelf life of products while maintaining cost-effectiveness.

Choosing the Right Material: Blend or Alloy

Polymer blends combine two or more polymers physically mixed to achieve tailored properties such as improved impact resistance or enhanced flexibility without chemical bonding. Polymer alloys involve chemically bonded polymers, offering superior thermal stability, mechanical strength, and uniform morphology for demanding applications. Selecting between a blend or alloy depends on performance requirements, processing methods, and cost considerations, with blends preferred for cost-effective customization and alloys for high-performance, durable materials.

Polymer Blend vs Polymer Alloy Infographic

materialdif.com

materialdif.com