Polystyrene offers excellent rigidity and clarity, making it ideal for disposable cutlery and packaging, while polyvinyl chloride (PVC) provides superior chemical resistance and durability, commonly used in plumbing pipes and vinyl flooring. Polystyrene is more brittle and less resistant to chemicals compared to the flexible and weather-resistant properties of PVC. Choosing between polystyrene and PVC depends on the required mechanical strength, flexibility, and environmental exposure of the application.

Table of Comparison

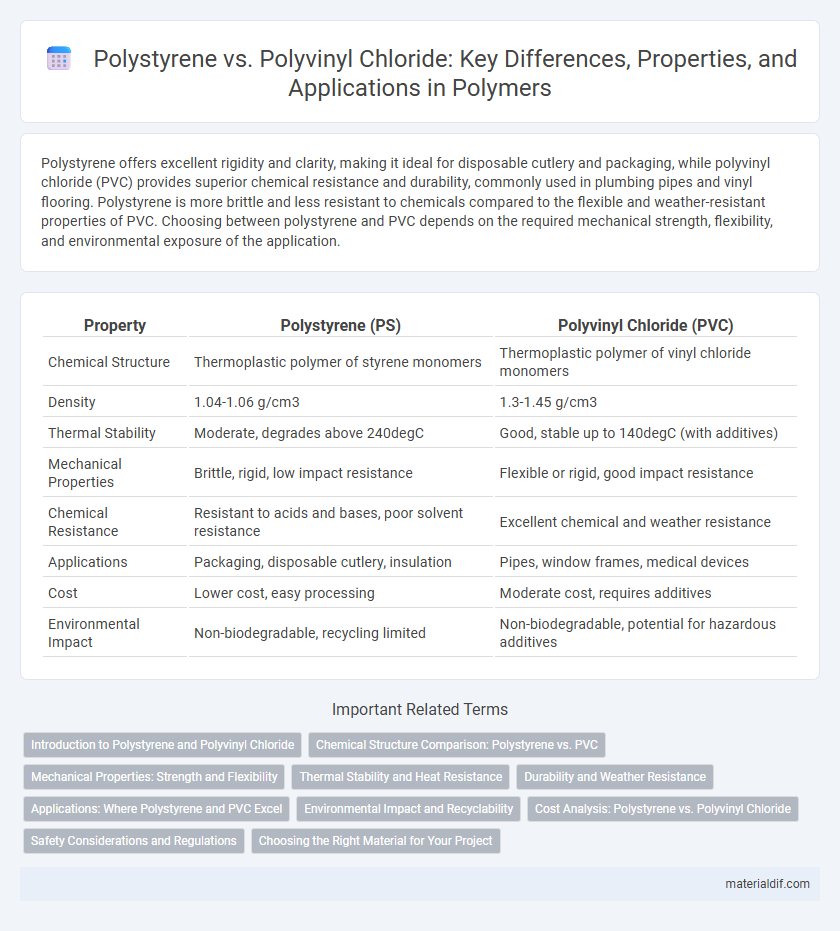

| Property | Polystyrene (PS) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Chemical Structure | Thermoplastic polymer of styrene monomers | Thermoplastic polymer of vinyl chloride monomers |

| Density | 1.04-1.06 g/cm3 | 1.3-1.45 g/cm3 |

| Thermal Stability | Moderate, degrades above 240degC | Good, stable up to 140degC (with additives) |

| Mechanical Properties | Brittle, rigid, low impact resistance | Flexible or rigid, good impact resistance |

| Chemical Resistance | Resistant to acids and bases, poor solvent resistance | Excellent chemical and weather resistance |

| Applications | Packaging, disposable cutlery, insulation | Pipes, window frames, medical devices |

| Cost | Lower cost, easy processing | Moderate cost, requires additives |

| Environmental Impact | Non-biodegradable, recycling limited | Non-biodegradable, potential for hazardous additives |

Introduction to Polystyrene and Polyvinyl Chloride

Polystyrene (PS) is a synthetic aromatic polymer made from the monomer styrene, characterized by its rigidity, clarity, and ease of fabrication, widely used in packaging, insulation, and disposable cutlery. Polyvinyl Chloride (PVC) is a versatile thermoplastic polymer derived from vinyl chloride monomers, known for its durability, chemical resistance, and flexibility, commonly applied in pipes, cables, and medical devices. Both polymers offer distinct physical properties and applications driven by their molecular structures, influencing their performance in various industrial and consumer products.

Chemical Structure Comparison: Polystyrene vs. PVC

Polystyrene consists of a hydrocarbon backbone with phenyl groups attached to every other carbon atom, providing rigidity and clarity due to the bulky aromatic rings. Polyvinyl chloride (PVC) features a hydrocarbon chain where every other hydrogen is replaced by a chlorine atom, resulting in increased chemical resistance and flame retardancy. This difference in side groups--phenyl in polystyrene versus chlorine in PVC--significantly influences the thermal stability, mechanical properties, and applications of these polymers.

Mechanical Properties: Strength and Flexibility

Polystyrene exhibits high tensile strength but is inherently brittle, limiting its flexibility and impact resistance compared to polyvinyl chloride (PVC). Polyvinyl chloride offers moderate tensile strength combined with superior flexibility and durability, making it ideal for applications requiring bending and resilience. The mechanical properties of PVC enable it to withstand repeated stress without cracking, contrasting with polystyrene's tendency to fracture under similar conditions.

Thermal Stability and Heat Resistance

Polystyrene exhibits lower thermal stability with a melting point around 240degC, making it susceptible to deformation under prolonged heat exposure. Polyvinyl chloride (PVC) offers superior heat resistance due to its higher thermal decomposition temperature near 140-260degC, enhanced by its chlorine content that provides flame retardancy. This difference makes PVC more suitable for applications demanding higher thermal endurance and flame resistance compared to polystyrene.

Durability and Weather Resistance

Polystyrene offers good rigidity but lacks the durability and weather resistance of polyvinyl chloride (PVC), making it less suitable for outdoor applications. PVC exhibits high resistance to UV radiation, moisture, and chemical exposure, ensuring long-lasting performance in harsh environmental conditions. This superior durability and weather resistance make PVC the preferred choice for construction and outdoor products.

Applications: Where Polystyrene and PVC Excel

Polystyrene excels in applications requiring clarity and rigidity, such as disposable cutlery, CD cases, and insulation materials due to its lightweight and impact resistance. Polyvinyl chloride (PVC) is preferred for construction materials, including pipes, window frames, and electrical cable insulation, thanks to its durability, chemical resistance, and fire retardant properties. Both polymers offer distinct advantages: polystyrene in packaging and consumer products, PVC in industrial and building applications.

Environmental Impact and Recyclability

Polystyrene generates significant environmental concerns due to its low biodegradability and challenges in recycling, often ending up in landfills or marine environments where it breaks down into harmful microplastics. Polyvinyl chloride (PVC) has a complex environmental footprint as its production releases toxic chemicals, but it benefits from more established recycling streams that can reduce waste and promote material recovery. Both polymers require improved waste management strategies to minimize their ecological impact and enhance circular economy outcomes.

Cost Analysis: Polystyrene vs. Polyvinyl Chloride

Polystyrene is generally more cost-effective than polyvinyl chloride (PVC) due to lower raw material and production expenses, making it ideal for applications requiring budget-friendly options. PVC's higher cost stems from its complex manufacturing process and added chlorine content, which enhances durability and chemical resistance. While polystyrene offers economic advantages, PVC provides superior performance in environments demanding higher strength and weather resistance.

Safety Considerations and Regulations

Polystyrene and polyvinyl chloride (PVC) differ significantly in safety considerations; polystyrene is generally recognized as safe for food packaging but can release styrene, a possible carcinogen, when heated or burned. PVC contains chlorine and may release harmful dioxins and phthalates during manufacturing or disposal, leading to stricter regulations under agencies such as the EPA and REACH. Compliance with safety standards like FDA approvals for food contact and strict handling protocols is critical for minimizing health and environmental risks associated with both polymers.

Choosing the Right Material for Your Project

Polystyrene offers excellent rigidity and clarity, making it ideal for packaging and disposable containers, while polyvinyl chloride (PVC) provides superior chemical resistance and durability, suitable for piping and construction materials. Polystyrene is lightweight and cost-effective but lacks the flexibility and weather resistance that PVC boasts. Selecting the right polymer depends on project requirements such as mechanical strength, environmental exposure, and budget constraints.

Polystyrene vs Polyvinyl Chloride Infographic

materialdif.com

materialdif.com