Polymer PET undergoes extrusion and calendering processes to shape materials with distinct properties. Extrusion forces molten PET through a die to create continuous shapes like films or sheets, offering uniform thickness and high production speed. Calendering presses PET between rollers to produce smooth, glossy surfaces with precise thickness control, ideal for applications requiring fine finishes.

Table of Comparison

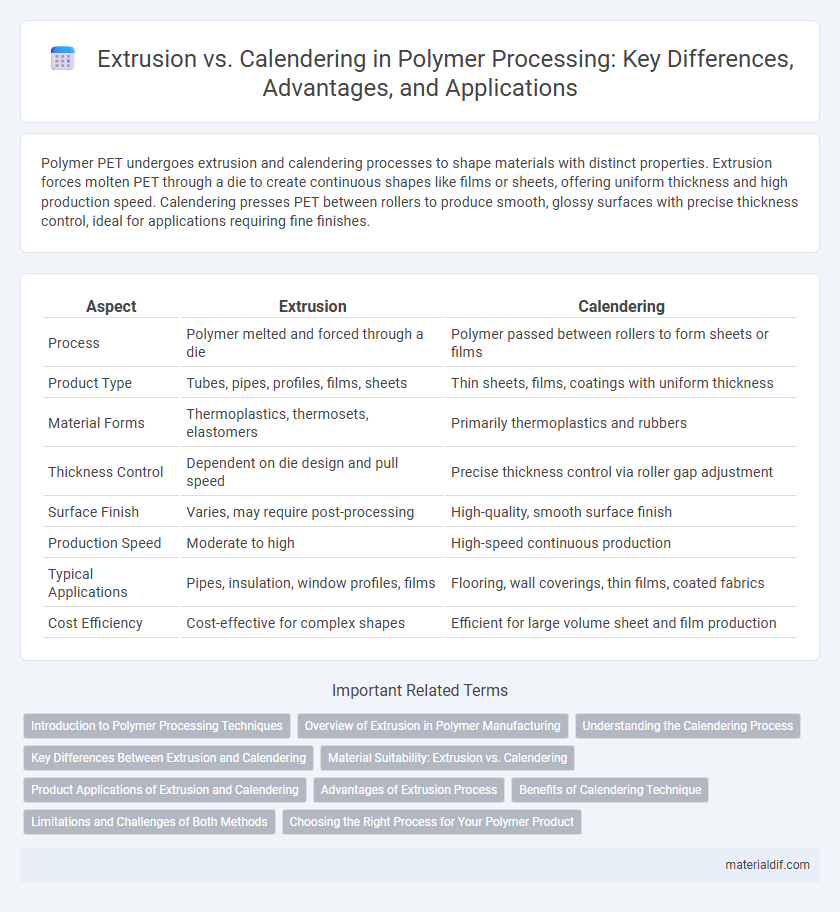

| Aspect | Extrusion | Calendering |

|---|---|---|

| Process | Polymer melted and forced through a die | Polymer passed between rollers to form sheets or films |

| Product Type | Tubes, pipes, profiles, films, sheets | Thin sheets, films, coatings with uniform thickness |

| Material Forms | Thermoplastics, thermosets, elastomers | Primarily thermoplastics and rubbers |

| Thickness Control | Dependent on die design and pull speed | Precise thickness control via roller gap adjustment |

| Surface Finish | Varies, may require post-processing | High-quality, smooth surface finish |

| Production Speed | Moderate to high | High-speed continuous production |

| Typical Applications | Pipes, insulation, window profiles, films | Flooring, wall coverings, thin films, coated fabrics |

| Cost Efficiency | Cost-effective for complex shapes | Efficient for large volume sheet and film production |

Introduction to Polymer Processing Techniques

Extrusion and calendering are key polymer processing techniques used to shape thermoplastic materials into continuous profiles or sheets. Extrusion forces molten polymer through a shaped die to create long, uniform products such as pipes and films, whereas calendering involves passing polymer melt between heated rollers to produce thin, smooth sheets with controlled thickness. Both methods optimize mechanical properties and surface finish depending on polymer type and processing conditions.

Overview of Extrusion in Polymer Manufacturing

Extrusion in polymer manufacturing involves melting raw polymer pellets and forcing the molten material through a shaped die to create continuous profiles such as pipes, sheets, or films. This process enables precise control over the cross-sectional geometry and is widely used for high-volume production of uniform products. Key parameters influencing extrusion quality include temperature, screw speed, and die design, which collectively affect the polymer's melt flow and final product characteristics.

Understanding the Calendering Process

Calendering is a polymer processing technique where molten polymer is passed between heated rollers to produce thin, uniform sheets with precise thickness control and smooth surfaces. This process offers high production rates and excellent dimensional accuracy, making it ideal for materials like PVC and rubber. Unlike extrusion, which pushes molten polymer through a die, calendering relies on pressure and heat from rollers to shape polymers into flat films or sheets.

Key Differences Between Extrusion and Calendering

Extrusion involves forcing molten polymer through a shaped die to create continuous profiles, while calendering uses rollers to form thin polymer sheets with precise thickness control. Extrusion is ideal for producing pipes, tubes, and complex cross-sections, whereas calendering excels in manufacturing films, sheets, and coatings with uniform surface finish. Key differences include the production method, product shape, and flexibility in controlling thickness and texture.

Material Suitability: Extrusion vs. Calendering

Extrusion is highly suitable for thermoplastics and elastomers with a wide range of viscosities, allowing continuous production of complex cross-sectional profiles such as pipes and films. Calendering is optimal for processing polymers with high melt strength and viscosity, like PVC and rubber, to produce thin, uniform sheets with smooth surfaces. Material selection depends on target product geometry and thermal properties, as extrusion handles 3D shapes, while calendering excels in flat sheet manufacturing.

Product Applications of Extrusion and Calendering

Extrusion is widely used for manufacturing plastic pipes, tubing, and profiles due to its ability to produce continuous lengths with consistent cross-sectional shapes. Calendering is preferred for producing thin polymer sheets, films, and coated fabrics, offering precise control over thickness and surface texture. Both processes cater to diverse applications in automotive parts, packaging materials, and flexible electronics, leveraging their distinct product output advantages.

Advantages of Extrusion Process

Extrusion offers continuous production capabilities, enabling efficient manufacturing of complex polymer profiles with consistent cross-sectional shapes. This process provides excellent dimensional control and high throughput, making it ideal for producing pipes, films, and sheets with uniform thickness. Extrusion also allows for easy integration of fillers and additives, enhancing material properties without compromising process stability.

Benefits of Calendering Technique

Calendering provides superior surface finish and dimensional control for polymer sheets, enhancing product quality and consistency. This technique allows precise thickness adjustment and smooth texture, ideal for flexible films and coatings in packaging and textiles. High production speed and cost efficiency make calendering advantageous for large-volume polymer processing applications.

Limitations and Challenges of Both Methods

Extrusion faces limitations in producing complex cross-sectional shapes and often struggles with achieving consistent thickness and surface finish in intricate profiles. Calendering is challenged by the need for precise roll temperature control to prevent defects such as thickness variations and surface marks, and it is less suitable for processing highly viscous polymers. Both methods encounter difficulties in maintaining uniformity and quality at high production speeds, impacting the scalability and consistency of polymer sheets and films.

Choosing the Right Process for Your Polymer Product

Selecting the appropriate polymer processing method depends on the product's design and performance requirements, with extrusion excelling in producing continuous profiles and complex cross-sections like pipes and films. Calendering offers superior control over sheet thickness and surface finish, making it ideal for producing thin, smooth polymer sheets and coated fabrics. Evaluating factors such as desired material thickness, surface characteristics, production volume, and cost-efficiency ensures optimal results in polymer product manufacturing.

Extrusion vs Calendering Infographic

materialdif.com

materialdif.com