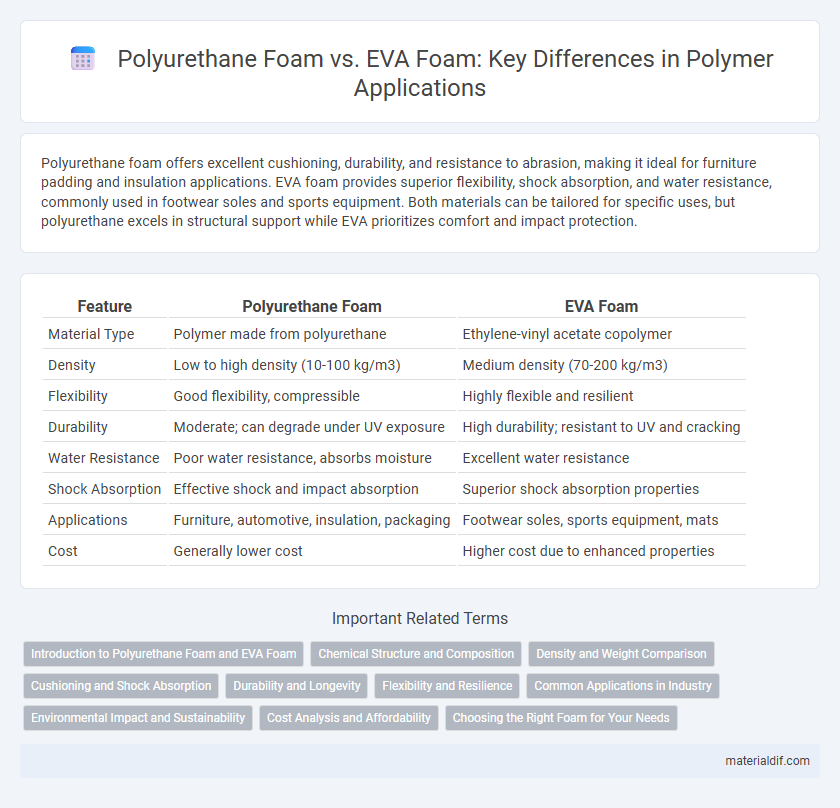

Polyurethane foam offers excellent cushioning, durability, and resistance to abrasion, making it ideal for furniture padding and insulation applications. EVA foam provides superior flexibility, shock absorption, and water resistance, commonly used in footwear soles and sports equipment. Both materials can be tailored for specific uses, but polyurethane excels in structural support while EVA prioritizes comfort and impact protection.

Table of Comparison

| Feature | Polyurethane Foam | EVA Foam |

|---|---|---|

| Material Type | Polymer made from polyurethane | Ethylene-vinyl acetate copolymer |

| Density | Low to high density (10-100 kg/m3) | Medium density (70-200 kg/m3) |

| Flexibility | Good flexibility, compressible | Highly flexible and resilient |

| Durability | Moderate; can degrade under UV exposure | High durability; resistant to UV and cracking |

| Water Resistance | Poor water resistance, absorbs moisture | Excellent water resistance |

| Shock Absorption | Effective shock and impact absorption | Superior shock absorption properties |

| Applications | Furniture, automotive, insulation, packaging | Footwear soles, sports equipment, mats |

| Cost | Generally lower cost | Higher cost due to enhanced properties |

Introduction to Polyurethane Foam and EVA Foam

Polyurethane foam is a versatile polymer widely used for cushioning, insulation, and packaging due to its excellent flexibility and durability. EVA foam, or ethylene-vinyl acetate foam, is known for its lightweight, shock-absorbent properties, making it popular in footwear and sports equipment. Both foams differ in chemical composition and physical properties, influencing their specific applications in consumer and industrial products.

Chemical Structure and Composition

Polyurethane foam consists of polymer chains formed from the reaction of polyols and diisocyanates, resulting in a flexible, cross-linked structure with urethane linkages. EVA (ethylene-vinyl acetate) foam is a copolymer composed of ethylene and vinyl acetate monomers, creating a thermoplastic with a soft, rubber-like consistency and linear polymer chains. The chemical composition difference influences properties such as flexibility, durability, and resistance to chemicals and UV exposure in various applications.

Density and Weight Comparison

Polyurethane foam typically exhibits higher density than EVA foam, ranging from 1.8 to 3.0 pounds per cubic foot compared to EVA's 1.2 to 2.5 pounds per cubic foot, influencing overall weight and cushioning properties. The increased density in polyurethane foam results in greater durability and support but can add more weight to applications like footwear and padding. EVA foam's lower density provides lighter material choice, enhancing portability and comfort in athletic and casual products.

Cushioning and Shock Absorption

Polyurethane foam offers superior cushioning and shock absorption due to its open-cell structure, which efficiently disperses impact forces and provides long-lasting comfort. EVA foam, while also effective, features a closed-cell design that delivers firmer support and better resistance to compression, making it ideal for high-impact activities. Both materials are popular in footwear and sports equipment, with polyurethane foam favored for softer cushioning and EVA foam preferred for enhanced durability and shock resistance.

Durability and Longevity

Polyurethane foam offers superior durability and longevity due to its high resistance to abrasion, compression, and chemical degradation, making it ideal for heavy-duty applications. EVA foam, while providing excellent cushioning and flexibility, tends to wear down faster under continuous stress and exposure to harsh environments. Polyurethane's cross-linked polymer structure ensures longer life span compared to the more open-cell structure of EVA foam, which is prone to faster breakdown.

Flexibility and Resilience

Polyurethane foam exhibits superior flexibility and resilience due to its open-cell structure, allowing it to compress and recover rapidly under pressure, making it ideal for cushioning and insulation. EVA foam offers moderate flexibility with a closed-cell design, providing good shock absorption and durability, commonly used in footwear and sports equipment. Polyurethane's elasticity outperforms EVA foam in applications requiring repeated deformation and long-term durability.

Common Applications in Industry

Polyurethane foam is extensively used in automotive seating, insulation panels, and furniture cushioning due to its excellent durability and flexibility. EVA foam is popular in the footwear industry, sporting goods, and packaging applications because of its shock-absorbing properties and lightweight structure. Both materials serve critical roles in manufacturing, with polyurethane foam favored for comfort and thermal insulation, while EVA foam is preferred for impact resistance and water resistance.

Environmental Impact and Sustainability

Polyurethane foam, widely used in insulation and furniture, poses significant environmental challenges due to its non-biodegradable nature and reliance on petrochemical resources, leading to persistent landfill waste and high carbon emissions during production. EVA foam, commonly found in footwear and sports equipment, offers improved recyclability and lower toxicity, making it a more sustainable option with reduced environmental footprint throughout its lifecycle. Choosing EVA foam supports circular economy initiatives by enabling easier recycling processes and minimizing harmful chemical release compared to traditional polyurethane foam.

Cost Analysis and Affordability

Polyurethane foam generally offers a lower cost per unit compared to EVA foam, making it a cost-effective choice for large-scale applications such as insulation and cushioning. EVA foam, while more expensive, provides enhanced durability and flexibility, which can reduce replacement frequency and maintenance costs over time. Evaluating total lifecycle expenses reveals polyurethane foam as more affordable initially, but EVA foam may deliver better value through extended usability in premium products.

Choosing the Right Foam for Your Needs

Polyurethane foam offers excellent cushioning and durability, making it ideal for applications requiring heavy-duty support and impact absorption. EVA foam provides superior flexibility, lightweight comfort, and water resistance, suitable for footwear, sports gear, and seals. Selecting the right foam depends on factors such as load bearing, environmental exposure, and desired elasticity in your specific use case.

Polyurethane Foam vs EVA Foam Infographic

materialdif.com

materialdif.com