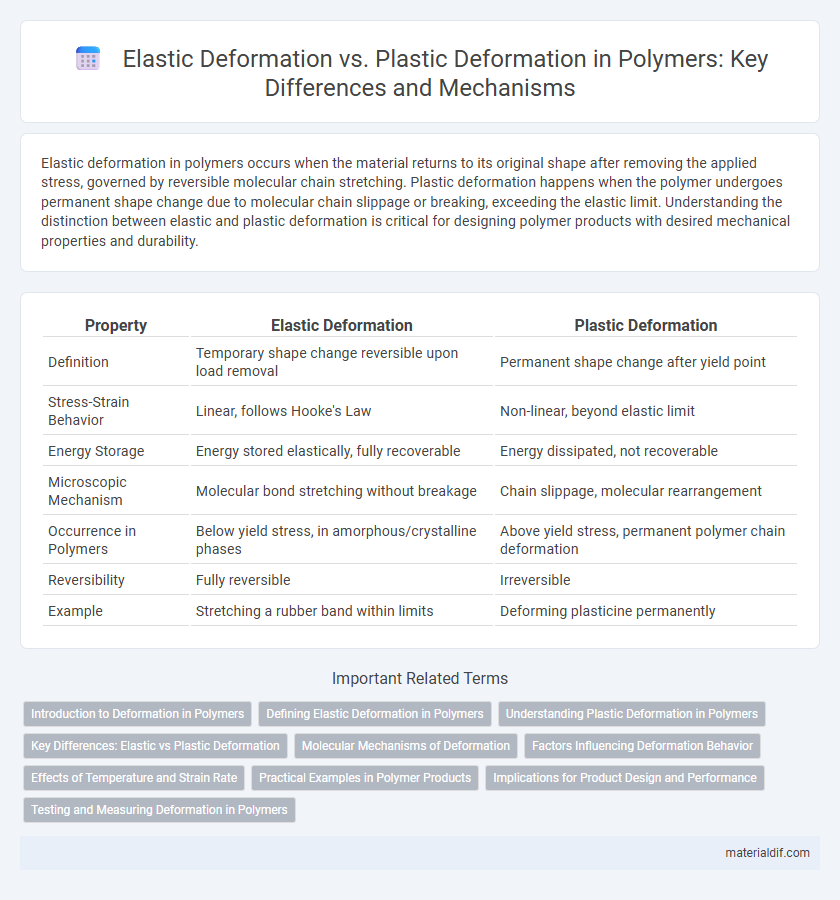

Elastic deformation in polymers occurs when the material returns to its original shape after removing the applied stress, governed by reversible molecular chain stretching. Plastic deformation happens when the polymer undergoes permanent shape change due to molecular chain slippage or breaking, exceeding the elastic limit. Understanding the distinction between elastic and plastic deformation is critical for designing polymer products with desired mechanical properties and durability.

Table of Comparison

| Property | Elastic Deformation | Plastic Deformation |

|---|---|---|

| Definition | Temporary shape change reversible upon load removal | Permanent shape change after yield point |

| Stress-Strain Behavior | Linear, follows Hooke's Law | Non-linear, beyond elastic limit |

| Energy Storage | Energy stored elastically, fully recoverable | Energy dissipated, not recoverable |

| Microscopic Mechanism | Molecular bond stretching without breakage | Chain slippage, molecular rearrangement |

| Occurrence in Polymers | Below yield stress, in amorphous/crystalline phases | Above yield stress, permanent polymer chain deformation |

| Reversibility | Fully reversible | Irreversible |

| Example | Stretching a rubber band within limits | Deforming plasticine permanently |

Introduction to Deformation in Polymers

Elastic deformation in polymers refers to the reversible change in shape under stress, where molecular chains stretch but return to their original configuration upon release. Plastic deformation occurs when the applied stress exceeds the polymer's yield point, causing permanent molecular chain slippage and reorientation. Understanding these deformation mechanisms is critical for predicting polymer behavior in applications involving mechanical load and strain.

Defining Elastic Deformation in Polymers

Elastic deformation in polymers refers to the reversible change in shape or size when subjected to stress, where the polymer chains temporarily stretch or uncoil but return to their original configuration once the load is removed. This phenomenon occurs within the polymer's elastic limit, typically characterized by linear stress-strain behavior and governed by the material's modulus of elasticity. Understanding elastic deformation is crucial for applications relying on polymers' ability to absorb energy and recover without permanent structural changes.

Understanding Plastic Deformation in Polymers

Plastic deformation in polymers occurs when the material undergoes permanent shape change under stress, surpassing its elastic limit. This process involves the irreversible sliding or disentanglement of polymer chains, leading to a permanent molecular rearrangement. Understanding plastic deformation is crucial for applications requiring durability and impact resistance, as it reflects the material's ability to absorb energy without fracturing.

Key Differences: Elastic vs Plastic Deformation

Elastic deformation in polymers is characterized by reversible shape changes where the material returns to its original form once the applied stress is removed, primarily due to stretching of molecular chains without permanent bond breakage. Plastic deformation involves permanent, irreversible changes caused by the sliding and reorganization of polymer chains beyond the yield point, resulting in permanent shape alteration. The key difference lies in elasticity being a temporary, recoverable strain, while plastic deformation causes permanent molecular rearrangement and structural changes in the polymer matrix.

Molecular Mechanisms of Deformation

Elastic deformation in polymers involves reversible stretching of molecular chains, where covalent bonds extend and recover their original length upon unloading. Plastic deformation occurs when the applied stress exceeds the polymer's yield strength, causing permanent chain slippage, disentanglement, and reorientation through mechanisms such as chain segment sliding and crystallite deformation. These molecular changes dictate the polymer's mechanical behavior and influence properties like toughness and ductility.

Factors Influencing Deformation Behavior

Temperature significantly influences polymer deformation behavior, with higher temperatures typically enhancing elastic deformation due to increased molecular mobility. The polymer's molecular structure, including chain length and cross-link density, dictates its capacity to return to its original shape or undergo permanent plastic deformation. External factors such as strain rate and applied stress further affect whether a polymer exhibits reversible elastic deformation or irreversible plastic flow.

Effects of Temperature and Strain Rate

Temperature significantly influences polymer deformation by increasing molecular mobility, which enhances elastic deformation at higher temperatures while promoting plastic flow at elevated strain rates. Elevated strain rates limit chain mobility, causing polymers to exhibit more brittle, elastic behavior, whereas lower strain rates facilitate plastic deformation by allowing molecular chains to rearrange. The interplay between temperature and strain rate determines whether a polymer undergoes reversible elastic deformation or permanent plastic deformation, critical for applications involving dynamic mechanical loading.

Practical Examples in Polymer Products

Elastic deformation in polymers occurs when materials like silicone rubber or thermoplastic elastomers return to their original shape after stretching, as seen in elastic bands or flexible seals. Plastic deformation takes place in products such as polyethylene containers and polycarbonate lenses, where permanent shape change happens after exceeding the yield point during molding or impact. Understanding these deformation behaviors is critical for optimizing polymer product design to ensure durability and performance under mechanical stress.

Implications for Product Design and Performance

Elastic deformation in polymers allows materials to return to their original shape after stress removal, crucial for applications requiring flexibility and durability. Plastic deformation results in permanent shape changes, affecting long-term product reliability and may lead to failure under repeated stress. Designers must balance these behaviors to optimize polymer performance in products like flexible electronics, automotive components, and packaging materials.

Testing and Measuring Deformation in Polymers

Testing and measuring deformation in polymers involves quantifying the elastic deformation, which is reversible strain occurring under stress, and plastic deformation, the permanent change beyond the yield point. Techniques such as tensile testing and dynamic mechanical analysis (DMA) capture stress-strain curves to distinguish between elastic modulus and plastic flow behavior. Accurate measurement of these deformation modes is critical for predicting polymer performance under mechanical loads and optimizing material formulations.

Elastic Deformation vs Plastic Deformation Infographic

materialdif.com

materialdif.com