Single-use polymers are designed for limited applications and often contribute significantly to environmental pollution due to their inability to be effectively reused. Recyclable polymers, on the other hand, offer a sustainable alternative by allowing material recovery and reducing waste through multiple life cycles. Prioritizing recyclable polymers supports circular economy initiatives and minimizes the ecological footprint of plastic consumption.

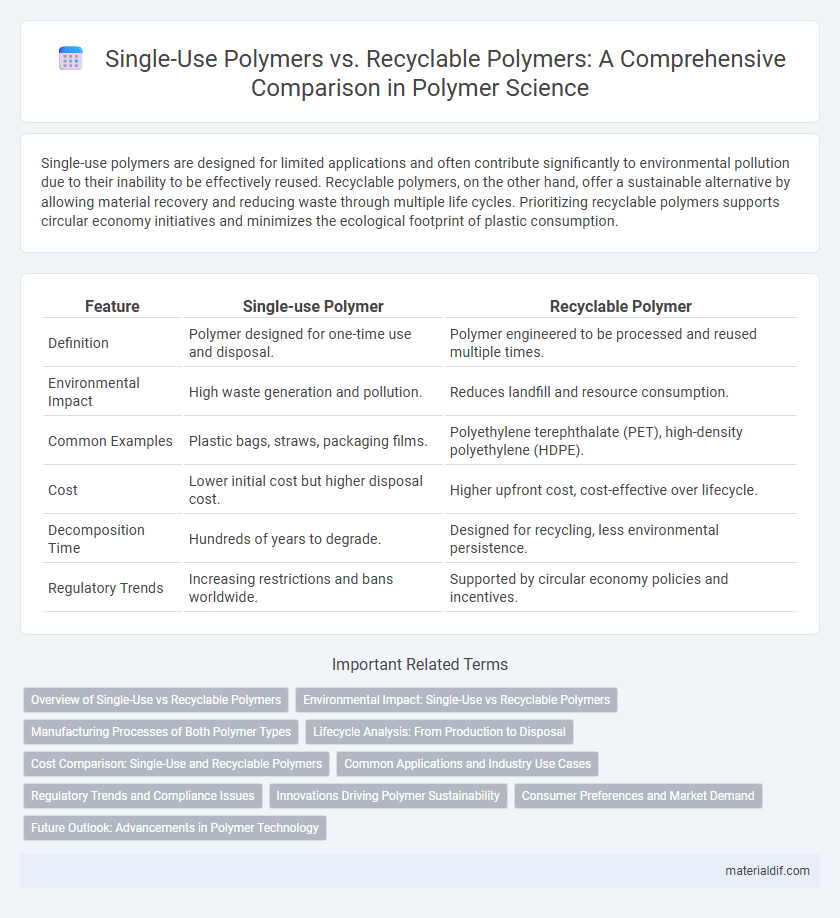

Table of Comparison

| Feature | Single-use Polymer | Recyclable Polymer |

|---|---|---|

| Definition | Polymer designed for one-time use and disposal. | Polymer engineered to be processed and reused multiple times. |

| Environmental Impact | High waste generation and pollution. | Reduces landfill and resource consumption. |

| Common Examples | Plastic bags, straws, packaging films. | Polyethylene terephthalate (PET), high-density polyethylene (HDPE). |

| Cost | Lower initial cost but higher disposal cost. | Higher upfront cost, cost-effective over lifecycle. |

| Decomposition Time | Hundreds of years to degrade. | Designed for recycling, less environmental persistence. |

| Regulatory Trends | Increasing restrictions and bans worldwide. | Supported by circular economy policies and incentives. |

Overview of Single-Use vs Recyclable Polymers

Single-use polymers, primarily made from polyethylene and polystyrene, are designed for transient applications and often contribute heavily to environmental pollution due to limited recycling rates. Recyclable polymers, such as PET and HDPE, possess molecular structures that enable efficient recovery and reuse, supporting circular economy principles. Transitioning from single-use to recyclable polymers significantly reduces plastic waste and enhances sustainability in packaging and product design.

Environmental Impact: Single-Use vs Recyclable Polymers

Single-use polymers contribute significantly to environmental pollution due to their short lifecycle and the accumulation of non-biodegradable waste in landfills and oceans. Recyclable polymers reduce ecological footprint by enabling material recovery and reuse, thus lowering the demand for virgin plastic production and decreasing greenhouse gas emissions. Transitioning to recyclable polymers supports sustainable waste management and mitigates long-term environmental degradation caused by plastic persistence.

Manufacturing Processes of Both Polymer Types

Single-use polymers are typically manufactured through cost-effective processes such as extrusion or injection molding, emphasizing high volume and rapid production with minimal regard for end-of-life management. Recyclable polymers often involve advanced manufacturing techniques like compatibilization and polymer blending to enhance material recovery and maintain mechanical properties during multiple processing cycles. Incorporating additives and stabilizers during production of recyclable polymers improves durability and facilitates efficient sorting and reprocessing in recycling facilities.

Lifecycle Analysis: From Production to Disposal

Single-use polymers often exhibit a shorter lifecycle with significant environmental impacts due to their production from virgin fossil fuels and limited post-consumer recyclability, leading to increased landfill accumulation and pollution. Recyclable polymers, such as PET and HDPE, offer enhanced lifecycle benefits by enabling multiple reuse cycles that reduce raw material extraction and energy consumption during production. Lifecycle analysis demonstrates that recyclable polymers contribute to lower greenhouse gas emissions and resource depletion compared to single-use polymers, emphasizing the importance of recycling infrastructure and material recovery efficiency.

Cost Comparison: Single-Use and Recyclable Polymers

Single-use polymers typically incur lower initial manufacturing costs due to simpler production processes and less stringent material requirements. Recyclable polymers often involve higher upfront expenses stemming from advanced formulations and the integration of additives that facilitate recycling. However, the long-term cost benefits of recyclable polymers emerge through reduced waste management fees and material recovery, leading to overall economic advantages in sustainable production cycles.

Common Applications and Industry Use Cases

Single-use polymers, commonly found in packaging materials, disposable cutlery, and medical devices, are widely used for their low cost and convenience but contribute significantly to environmental pollution. Recyclable polymers such as PET, HDPE, and PP are favored in industries like beverage bottling, automotive, and consumer goods packaging due to their ability to be reprocessed into new products, reducing waste and resource consumption. The shift towards recyclable polymers is driven by increasing regulations and corporate sustainability goals, promoting circular economy practices in manufacturing and supply chains.

Regulatory Trends and Compliance Issues

Regulatory trends increasingly favor recyclable polymers over single-use polymers to address environmental impact and promote circular economy practices. Compliance issues often involve stringent restrictions on single-use polymer production and disposal, with governments implementing extended producer responsibility (EPR) policies and plastic bans. Industry stakeholders must adapt to evolving legislation such as the EU's Single-Use Plastics Directive and global commitments to reduce plastic waste through improved recyclability standards.

Innovations Driving Polymer Sustainability

Innovations in polymer sustainability focus on developing recyclable polymers with enhanced biodegradability and improved mechanical properties, reducing reliance on single-use polymers that contribute to environmental pollution. Advanced chemical recycling techniques and bio-based polymer synthesis enable closed-loop systems, promoting circular economy principles within the plastics industry. Emerging technologies such as enzyme-catalyzed polymer degradation and polymer blending for recyclability drive significant progress in minimizing single-use polymer waste.

Consumer Preferences and Market Demand

Consumer preferences increasingly favor recyclable polymers due to growing environmental awareness and demand for sustainable packaging solutions. Market data reveals a shift towards eco-friendly materials, with recyclable polymers gaining a larger share in sectors like food packaging and electronics. Single-use polymers continue to face declining demand as regulatory policies and corporate commitments push for circular economy practices.

Future Outlook: Advancements in Polymer Technology

Emerging innovations in polymer technology prioritize the development of recyclable polymers with enhanced biodegradability and mechanical properties, aiming to reduce environmental impact compared to conventional single-use polymers. Advanced chemical recycling methods and bio-based polymer synthesis are projected to improve sustainability by enabling closed-loop recycling and reducing reliance on fossil fuels. Industry investment in smart polymers and nanocomposites is expected to drive large-scale adoption of recyclable materials, supporting circular economy goals and regulatory compliance.

Single-use Polymer vs Recyclable Polymer Infographic

materialdif.com

materialdif.com