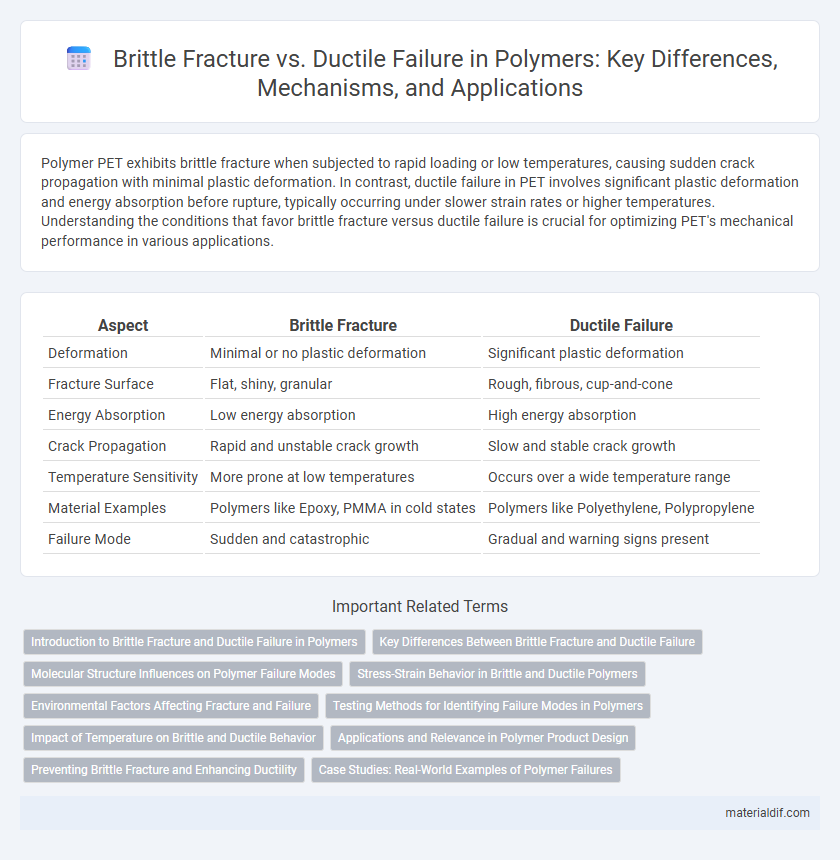

Polymer PET exhibits brittle fracture when subjected to rapid loading or low temperatures, causing sudden crack propagation with minimal plastic deformation. In contrast, ductile failure in PET involves significant plastic deformation and energy absorption before rupture, typically occurring under slower strain rates or higher temperatures. Understanding the conditions that favor brittle fracture versus ductile failure is crucial for optimizing PET's mechanical performance in various applications.

Table of Comparison

| Aspect | Brittle Fracture | Ductile Failure |

|---|---|---|

| Deformation | Minimal or no plastic deformation | Significant plastic deformation |

| Fracture Surface | Flat, shiny, granular | Rough, fibrous, cup-and-cone |

| Energy Absorption | Low energy absorption | High energy absorption |

| Crack Propagation | Rapid and unstable crack growth | Slow and stable crack growth |

| Temperature Sensitivity | More prone at low temperatures | Occurs over a wide temperature range |

| Material Examples | Polymers like Epoxy, PMMA in cold states | Polymers like Polyethylene, Polypropylene |

| Failure Mode | Sudden and catastrophic | Gradual and warning signs present |

Introduction to Brittle Fracture and Ductile Failure in Polymers

Brittle fracture in polymers occurs when the material fails suddenly without significant plastic deformation, often due to low temperatures or high strain rates. Ductile failure involves considerable plastic deformation before fracture, characterized by chain mobility and energy dissipation through molecular rearrangements. Understanding these failure mechanisms is essential for predicting polymer performance under varied mechanical stresses and environmental conditions.

Key Differences Between Brittle Fracture and Ductile Failure

Brittle fracture in polymers occurs without significant plastic deformation, leading to a sudden and catastrophic failure, whereas ductile failure involves considerable plastic deformation before rupture, allowing for energy absorption. The microscopic mechanism in brittle fracture is crack propagation along polymer chains or through amorphous regions, while ductile failure is characterized by extensive molecular chain stretching and crazing. Temperature, strain rate, and polymer morphology greatly influence whether a polymer exhibits brittle fracture or ductile failure.

Molecular Structure Influences on Polymer Failure Modes

Polymer failure modes such as brittle fracture and ductile failure are predominantly influenced by the molecular structure, including chain length, degree of crosslinking, and crystallinity. High crosslink density and short chain lengths typically restrict molecular mobility, leading to brittle fracture under stress. Conversely, polymers with longer chains and lower crystallinity exhibit enhanced chain mobility, promoting ductile failure mechanisms through molecular disentanglement and plastic deformation.

Stress-Strain Behavior in Brittle and Ductile Polymers

Brittle polymers exhibit a sharp stress-strain curve with minimal plastic deformation, fracturing suddenly after reaching their elastic limit, as seen in materials like polystyrene. Ductile polymers such as polyethylene show significant plastic deformation with a gradual stress decline post-yield, indicating energy absorption before failure. The distinction in stress-strain behavior arises from differences in molecular mobility and chain entanglement, influencing toughness and failure mode.

Environmental Factors Affecting Fracture and Failure

Environmental factors such as temperature, humidity, and exposure to chemicals significantly influence brittle fracture and ductile failure in polymers. Low temperatures typically increase brittleness by reducing polymer chain mobility, while high humidity or chemical exposure can lead to environmental stress cracking and accelerated degradation. UV radiation also affects polymer microstructures, promoting embrittlement and shifting failure modes from ductile to brittle under certain conditions.

Testing Methods for Identifying Failure Modes in Polymers

Testing methods for identifying brittle fracture and ductile failure in polymers include tensile testing, impact testing, and fracture toughness measurements. Tensile testing evaluates elongation and stress at break to distinguish ductile behavior, while impact tests such as Charpy or Izod assess energy absorption indicative of brittle or ductile failure. Fracture toughness testing provides critical stress intensity factors that help characterize crack propagation tendencies in polymer materials.

Impact of Temperature on Brittle and Ductile Behavior

Temperature significantly influences the mechanical behavior of polymers, where low temperatures tend to promote brittle fracture due to reduced molecular mobility and increased material stiffness. As temperature rises, polymers exhibit enhanced ductility because increased chain segment movement allows plastic deformation before failure. The transition from brittle to ductile behavior often occurs over a temperature range known as the glass transition region, critical for designing polymer applications subject to varying thermal environments.

Applications and Relevance in Polymer Product Design

Brittle fracture in polymers occurs with minimal plastic deformation, making it critical for applications requiring high impact resistance, such as protective gear and automotive components. Ductile failure, characterized by significant elongation before rupture, is advantageous in flexible products like films and elastomers, where durability and flexibility are essential. Understanding these failure modes enables engineers to optimize polymer product design for performance, safety, and longevity across diverse industries.

Preventing Brittle Fracture and Enhancing Ductility

Preventing brittle fracture in polymers involves controlling temperature conditions and utilizing materials with higher impact resistance to avoid sudden crack propagation. Enhancing ductility can be achieved by incorporating plasticizers, copolymers, or flexible segments into the polymer chain to improve molecular mobility and energy absorption. Optimizing polymer blend composition and processing parameters also plays a critical role in promoting ductile failure mechanisms and extending material lifespan.

Case Studies: Real-World Examples of Polymer Failures

Analyzing polymer failures in real-world applications reveals Brittle Fracture often occurs in low-temperature environments where rapid crack propagation dominates, as demonstrated by failures in polyethylene pipelines and polycarbonate military helmets. Ductile Failure is frequently observed in flexible polymers like polyurethane foams and rubber seals, where extensive plastic deformation precedes rupture, exemplified by automobile tires and flexible electronic housings. Case studies emphasize the critical role of polymer morphology, environmental conditions, and loading rates in determining whether a brittle fracture or ductile failure mode manifests in practical settings.

Brittle Fracture vs Ductile Failure Infographic

materialdif.com

materialdif.com