Cross-linking in polymers involves creating covalent bonds between polymer chains, enhancing mechanical strength and thermal stability by forming a three-dimensional network. Grafting, on the other hand, attaches side chains onto a polymer backbone, modifying surface properties and compatibility without significantly altering the bulk structure. Both methods tailor polymer characteristics, but cross-linking primarily improves durability while grafting enhances functionality and processability.

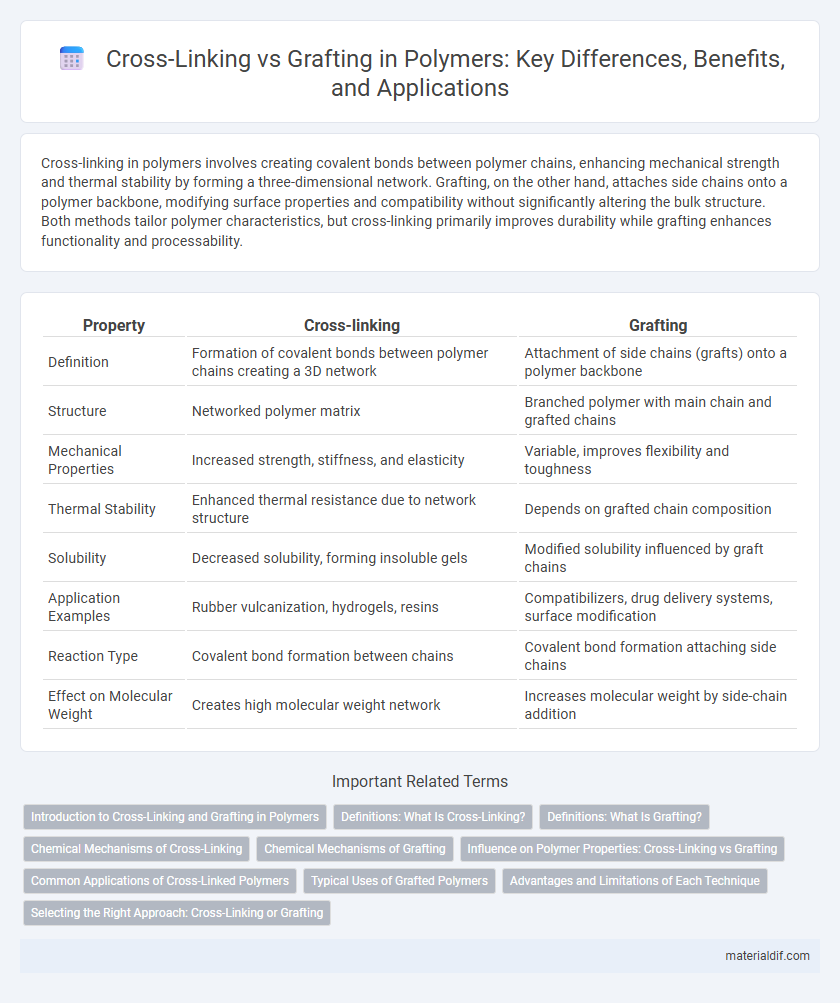

Table of Comparison

| Property | Cross-linking | Grafting |

|---|---|---|

| Definition | Formation of covalent bonds between polymer chains creating a 3D network | Attachment of side chains (grafts) onto a polymer backbone |

| Structure | Networked polymer matrix | Branched polymer with main chain and grafted chains |

| Mechanical Properties | Increased strength, stiffness, and elasticity | Variable, improves flexibility and toughness |

| Thermal Stability | Enhanced thermal resistance due to network structure | Depends on grafted chain composition |

| Solubility | Decreased solubility, forming insoluble gels | Modified solubility influenced by graft chains |

| Application Examples | Rubber vulcanization, hydrogels, resins | Compatibilizers, drug delivery systems, surface modification |

| Reaction Type | Covalent bond formation between chains | Covalent bond formation attaching side chains |

| Effect on Molecular Weight | Creates high molecular weight network | Increases molecular weight by side-chain addition |

Introduction to Cross-Linking and Grafting in Polymers

Cross-linking in polymers forms covalent bonds between polymer chains, enhancing mechanical strength, thermal stability, and chemical resistance. Grafting involves attaching side chains of different polymers onto a main polymer backbone, allowing customization of surface properties and compatibility. These modification techniques tailor polymer performance for specific industrial applications such as coatings, adhesives, and biomedical devices.

Definitions: What Is Cross-Linking?

Cross-linking in polymers refers to the process where polymer chains are chemically bonded through covalent or ionic links, creating a three-dimensional network that enhances mechanical strength and thermal stability. This process differs from grafting, which involves attaching side chains or branches onto a polymer backbone without forming a network structure. Cross-linked polymers exhibit increased elasticity, resistance to solvents, and improved durability compared to their linear or grafted counterparts.

Definitions: What Is Grafting?

Grafting in polymers is a chemical process where side chains are covalently bonded to the backbone of a polymer, altering its physical and chemical properties. This technique enhances compatibility between different polymers or introduces specific functional groups to improve performance. Unlike cross-linking, which connects polymer chains to form a network, grafting modifies polymer surfaces or structures without creating a three-dimensional network.

Chemical Mechanisms of Cross-Linking

Cross-linking in polymers involves the formation of covalent bonds between polymer chains, creating a three-dimensional network that enhances mechanical strength and thermal stability. Common chemical mechanisms include free radical cross-linking, where initiators generate radicals that link chains, and condensation reactions, which form cross-links through elimination of small molecules like water. These mechanisms differ from grafting, which selectively attaches side chains onto a backbone without forming extensive networks, affecting polymer properties in distinct ways.

Chemical Mechanisms of Grafting

Grafting in polymers involves the formation of covalent bonds between polymer chains through reactive sites, typically initiated by free radicals, ionic species, or via photochemical processes. This chemical mechanism enables the attachment of side chains onto a polymer backbone, enhancing material properties such as mechanical strength and chemical resistance. Unlike cross-linking, grafting allows precise control over the functionality and architecture of the polymer by selectively modifying specific sites.

Influence on Polymer Properties: Cross-Linking vs Grafting

Cross-linking enhances polymer rigidity, thermal stability, and solvent resistance by forming covalent bonds between polymer chains, resulting in a three-dimensional network structure. Grafting introduces functional side chains onto a polymer backbone, improving surface properties, compatibility, and chemical reactivity without significantly altering the bulk material's mechanical strength. The degree and type of cross-linking or grafting directly influence polymer elasticity, tensile strength, and degradation behavior for targeted application performance.

Common Applications of Cross-Linked Polymers

Cross-linked polymers are widely used in applications requiring enhanced mechanical strength, thermal stability, and chemical resistance, such as in rubber tires, hydrogels, and epoxy resins for coatings and adhesives. The cross-linking process forms a three-dimensional network that improves durability and elasticity, making these materials ideal for automotive parts, medical devices, and packaging films. Unlike grafting, which modifies polymer chains by attaching side chains, cross-linking fundamentally alters the polymer structure to achieve superior performance in demanding environments.

Typical Uses of Grafted Polymers

Grafted polymers are commonly used in biomedical applications to enhance biocompatibility and drug delivery systems by attaching functional groups that improve interaction with biological tissues. They serve a crucial role in creating hydrogels with tailored properties for controlled release and wound dressing materials. In addition, grafted polymers are widely employed in water treatment and adhesives, where modified surface characteristics improve performance under specific environmental conditions.

Advantages and Limitations of Each Technique

Cross-linking enhances polymer network stability and mechanical strength by forming covalent bonds between polymer chains, but it can reduce flexibility and processability. Grafting improves polymer functionality and surface properties without significantly altering bulk characteristics, though it may result in heterogeneity and less control over molecular architecture. Both techniques offer tailored modifications for specific applications, balancing durability with customizable performance.

Selecting the Right Approach: Cross-Linking or Grafting

Selecting the right polymer modification approach depends on the desired material properties and application requirements. Cross-linking enhances mechanical strength and thermal stability by creating covalent bonds between polymer chains, ideal for applications needing elasticity and chemical resistance. Grafting introduces functional side chains to tailor surface properties or compatibility without significantly altering the polymer backbone, making it suitable for improving adhesion, biocompatibility, or chemical reactivity.

Cross-linking vs Grafting Infographic

materialdif.com

materialdif.com