Elastomers and plastomers differ significantly in their molecular structure, where elastomers exhibit high elasticity due to cross-linked polymer chains, allowing them to return to their original shape after deformation. Plastomers, on the other hand, possess a more linear or branched structure with less cross-linking, providing a balance between flexibility and stiffness ideal for applications requiring moderate elasticity and easy processability. Understanding these differences is crucial for selecting the appropriate polymer PET material to optimize performance in various industrial and consumer products.

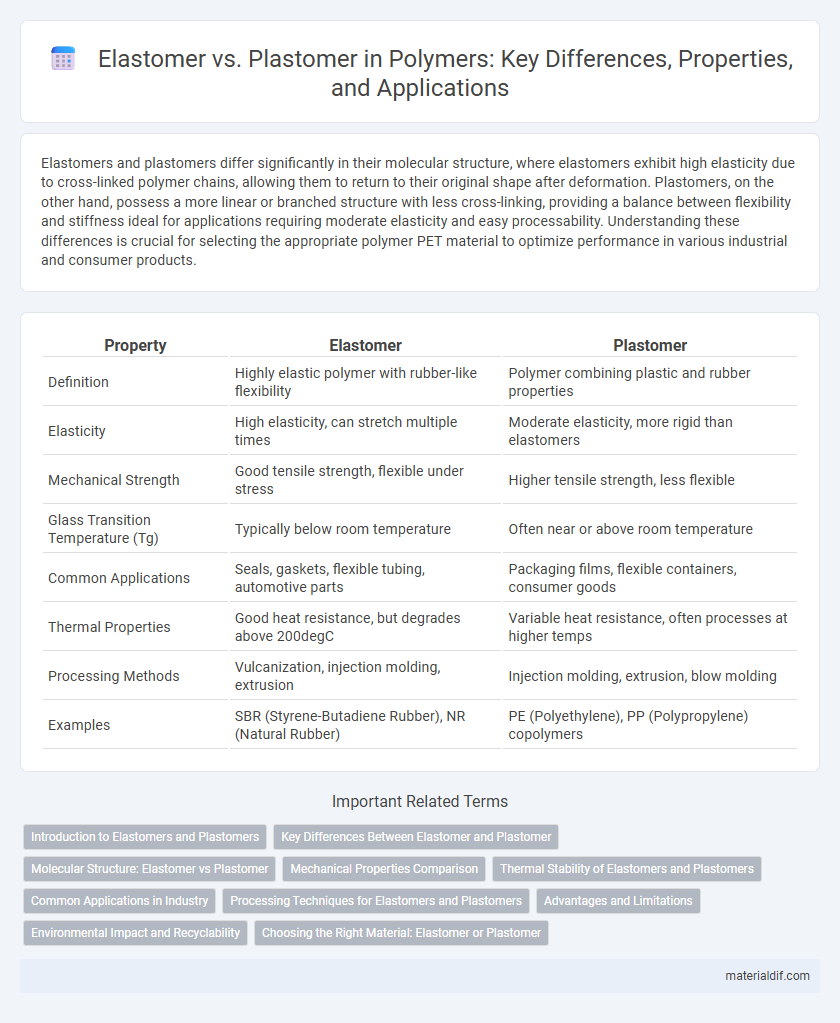

Table of Comparison

| Property | Elastomer | Plastomer |

|---|---|---|

| Definition | Highly elastic polymer with rubber-like flexibility | Polymer combining plastic and rubber properties |

| Elasticity | High elasticity, can stretch multiple times | Moderate elasticity, more rigid than elastomers |

| Mechanical Strength | Good tensile strength, flexible under stress | Higher tensile strength, less flexible |

| Glass Transition Temperature (Tg) | Typically below room temperature | Often near or above room temperature |

| Common Applications | Seals, gaskets, flexible tubing, automotive parts | Packaging films, flexible containers, consumer goods |

| Thermal Properties | Good heat resistance, but degrades above 200degC | Variable heat resistance, often processes at higher temps |

| Processing Methods | Vulcanization, injection molding, extrusion | Injection molding, extrusion, blow molding |

| Examples | SBR (Styrene-Butadiene Rubber), NR (Natural Rubber) | PE (Polyethylene), PP (Polypropylene) copolymers |

Introduction to Elastomers and Plastomers

Elastomers are polymers characterized by their high elasticity, allowing them to stretch significantly and return to their original shape, commonly used in applications like rubber bands and tires. Plastomers blend properties of plastics and elastomers, offering flexibility with processability, making them ideal for packaging and flexible films. The molecular structure of elastomers consists of loosely cross-linked polymer chains, while plastomers have a semi-crystalline structure that balances stiffness and softness.

Key Differences Between Elastomer and Plastomer

Elastomers exhibit high elasticity and can stretch significantly while returning to their original shape, making them ideal for applications requiring flexibility and resilience, such as rubber bands and automotive parts. Plastomers, a subclass of polyolefins, combine plastic and elastomeric properties, offering softness and flexibility without the extensive stretchability of elastomers, commonly used in film packaging and soft-touch consumer goods. Key differences include elastomers' cross-linked molecular structure providing superior elasticity versus plastomers' linear or branched structure yielding improved processability and rigidity balance.

Molecular Structure: Elastomer vs Plastomer

Elastomers possess a loosely cross-linked polymer network that enables high elasticity and reversible deformation under stress, while plastomers consist of linear or lightly branched polymer chains with minimal or no cross-linking, resulting in flexible yet plastic behavior. The molecular structure of elastomers includes long polymer chains connected by covalent bonds forming an elastic three-dimensional network, whereas plastomers feature semi-crystalline or amorphous regions that provide a balance between rigidity and flexibility. This fundamental difference in molecular architecture determines the distinct mechanical properties and applications of elastomers and plastomers in industries such as automotive and packaging.

Mechanical Properties Comparison

Elastomers exhibit high elasticity, allowing extensive deformation and rapid recovery, with tensile strengths typically ranging from 5 to 25 MPa and elongations at break exceeding 300%. Plastomers combine flexibility with enhanced stiffness, showing tensile strengths around 20 to 35 MPa and moderate elongation at break between 100% and 300%. The superior elasticity of elastomers makes them ideal for applications requiring impact resistance and flexibility, while plastomers offer better dimensional stability and load-bearing capacity.

Thermal Stability of Elastomers and Plastomers

Elastomers exhibit superior thermal stability compared to plastomers, maintaining elasticity at elevated temperatures due to their cross-linked polymer network. Plastomers, typically thermoplastic olefins, have lower thermal resistance and may soften or deform under heat stress, limiting their use in high-temperature applications. This thermal behavior makes elastomers preferable for components requiring durability in harsh thermal environments.

Common Applications in Industry

Elastomers are widely used in automotive seals, gaskets, and flexible hoses due to their excellent elasticity and durability. Plastomers find common applications in packaging films, wire insulation, and impact-resistant molded parts because of their balanced stiffness and clarity. Industries rely on elastomers for high-flexibility components, while plastomers serve needs requiring moderate flexibility with enhanced processing ease.

Processing Techniques for Elastomers and Plastomers

Elastomers are typically processed using techniques such as extrusion, injection molding, and compression molding, allowing for the production of flexible, resilient products with excellent elongation properties. Plastomers, a subclass of polyolefins, are processed similarly through injection molding and blow molding but benefit from enhanced processability and improved clarity due to their low crystallinity. Advanced processing methods like reactive extrusion enable the modification of both elastomers and plastomers to tailor mechanical properties for specialized applications.

Advantages and Limitations

Elastomers offer exceptional elasticity and resilience, making them ideal for applications requiring flexibility and impact resistance, such as automotive seals and footwear components. Plastomers provide better processability and clarity, suited for packaging and film applications due to their balanced stiffness and toughness. However, elastomers typically exhibit lower thermal stability, while plastomers may suffer from reduced elasticity and poorer performance under cyclic stress.

Environmental Impact and Recyclability

Elastomers, characterized by their flexible cross-linked polymer chains, often present recycling challenges due to their thermoset nature, leading to limited recyclability and greater environmental impact. Plastomers, a subclass of polyolefins with a semicrystalline structure, offer enhanced recyclability through mechanical recycling processes and contribute to lower environmental footprint by enabling material recovery and reuse. Lifecycle assessments reveal that incorporating plastomers in product design can reduce plastic waste accumulation and greenhouse gas emissions compared to conventional elastomer usage.

Choosing the Right Material: Elastomer or Plastomer

Choosing between elastomer and plastomer depends on the desired material properties and application requirements. Elastomers offer excellent elasticity and flexibility for applications needing high stretchability and resilience, such as seals and flexible joints, while plastomers provide superior rigidity and thermal stability suitable for structural components. Evaluating factors like mechanical strength, temperature resistance, and end-use environment ensures optimal performance when selecting between these polymers.

Elastomer vs Plastomer Infographic

materialdif.com

materialdif.com