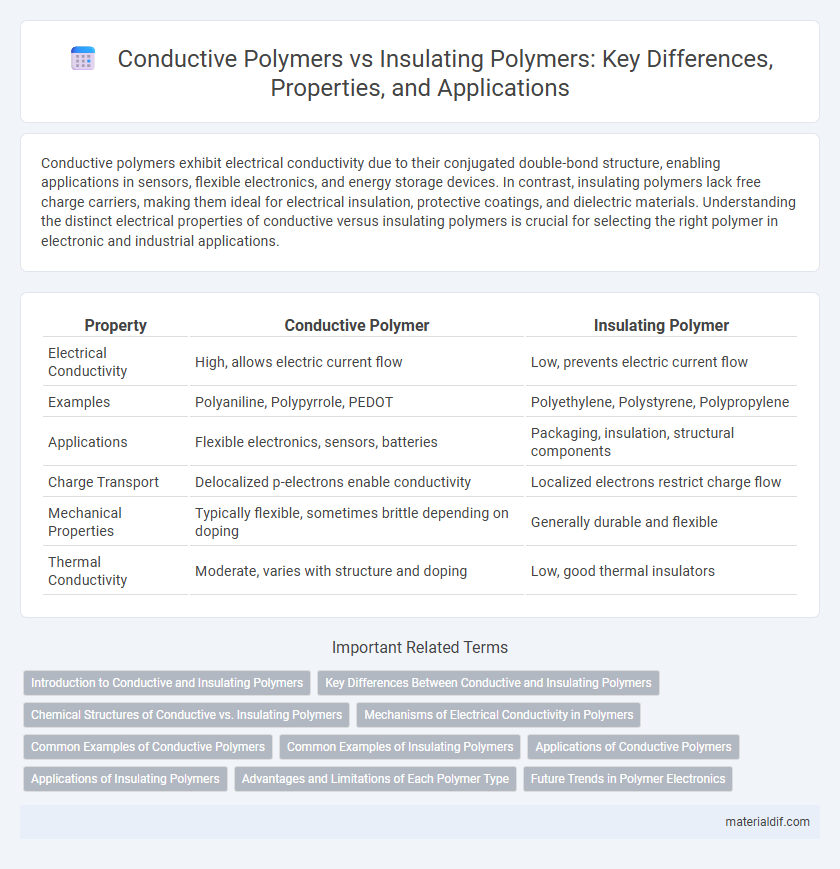

Conductive polymers exhibit electrical conductivity due to their conjugated double-bond structure, enabling applications in sensors, flexible electronics, and energy storage devices. In contrast, insulating polymers lack free charge carriers, making them ideal for electrical insulation, protective coatings, and dielectric materials. Understanding the distinct electrical properties of conductive versus insulating polymers is crucial for selecting the right polymer in electronic and industrial applications.

Table of Comparison

| Property | Conductive Polymer | Insulating Polymer |

|---|---|---|

| Electrical Conductivity | High, allows electric current flow | Low, prevents electric current flow |

| Examples | Polyaniline, Polypyrrole, PEDOT | Polyethylene, Polystyrene, Polypropylene |

| Applications | Flexible electronics, sensors, batteries | Packaging, insulation, structural components |

| Charge Transport | Delocalized p-electrons enable conductivity | Localized electrons restrict charge flow |

| Mechanical Properties | Typically flexible, sometimes brittle depending on doping | Generally durable and flexible |

| Thermal Conductivity | Moderate, varies with structure and doping | Low, good thermal insulators |

Introduction to Conductive and Insulating Polymers

Conductive polymers exhibit electrical conductivity due to their conjugated double bond structures, enabling electron movement along the polymer backbone. In contrast, insulating polymers lack this conjugation, resulting in high electrical resistivity and their primary use as electrical insulators. Key examples include polyaniline and polypyrrole for conductive polymers, while polyethylene and polystyrene serve as common insulating polymers.

Key Differences Between Conductive and Insulating Polymers

Conductive polymers, such as polyaniline and polythiophene, exhibit high electrical conductivity due to their conjugated pi-electron systems, enabling electron mobility along the polymer backbone. Insulating polymers like polyethylene and polystyrene lack conjugation and possess wide band gaps, resulting in low electrical conductivity and serving as effective electrical insulators. The key differences between conductive and insulating polymers lie in their molecular structure, electrical properties, and applications in electronic devices versus insulation materials.

Chemical Structures of Conductive vs. Insulating Polymers

Conductive polymers possess conjugated double bonds along their backbone, enabling delocalization of p-electrons which facilitates electrical conductivity, whereas insulating polymers have saturated bonds without conjugation, restricting electron mobility. The presence of alternating single and double bonds in conductive polymers like polyaniline or polythiophene contrasts with the fully saturated hydrocarbon chains of insulating polymers such as polyethylene or polypropylene. This fundamental difference in chemical structure dictates the electrical properties and applications of these polymer types.

Mechanisms of Electrical Conductivity in Polymers

Conductive polymers exhibit electrical conductivity through mechanisms such as charge carrier doping, which introduces free electrons or holes into the polymer backbone, enabling electron delocalization and charge transport. In contrast, insulating polymers lack conjugated p-electron systems and charge carriers, resulting in high electrical resistivity due to localized electron states and limited charge mobility. The extent of conjugation and the presence of dopants critically influence the electrical properties, distinguishing conductive polymers like polyaniline and polythiophene from typical insulating polymers such as polyethylene and polystyrene.

Common Examples of Conductive Polymers

Common examples of conductive polymers include polyaniline, polypyrrole, and poly(3,4-ethylenedioxythiophene) (PEDOT), which exhibit high electrical conductivity due to their conjugated polymer backbones. In contrast, insulating polymers such as polyethylene and polystyrene lack this conjugation, resulting in poor electrical conductivity. Conductive polymers are widely used in applications like organic electronics, sensors, and antistatic coatings owing to their tunable conductivity and processability.

Common Examples of Insulating Polymers

Common examples of insulating polymers include polyethylene, polystyrene, and polyvinyl chloride (PVC), all known for their excellent electrical resistance and widespread use in cable insulation, electronic components, and housings. These polymers possess high dielectric strength and low electrical conductivity, making them ideal for preventing electrical current flow in various applications. Their molecular structure, typically consisting of saturated hydrocarbons or aromatic rings without conjugated double bonds, contributes to their insulating properties.

Applications of Conductive Polymers

Conductive polymers are extensively used in flexible electronics, organic solar cells, and sensors due to their ability to conduct electricity while maintaining mechanical flexibility. Unlike insulating polymers, which serve primarily as electrical insulators in packaging and structural components, conductive polymers enable advancements in wearable devices, electromagnetic shielding, and organic light-emitting diodes (OLEDs). Their unique properties facilitate innovation in energy storage, bioelectronics, and smart coatings, distinguishing them in applications requiring both conductivity and polymeric versatility.

Applications of Insulating Polymers

Insulating polymers, such as polyethylene, polystyrene, and polyvinyl chloride, are widely used in electrical and electronic applications due to their high dielectric strength and excellent resistance to electrical conductivity. These materials are essential for coating wires, manufacturing circuit boards, and providing insulation in transformers and capacitors, ensuring safety and performance in various devices. Their thermal stability and chemical resistance further enhance their functionality in harsh environments, making them indispensable in automotive, aerospace, and consumer electronics industries.

Advantages and Limitations of Each Polymer Type

Conductive polymers offer advantages such as electrical conductivity, flexibility, and lightweight properties, making them ideal for applications in organic electronics, sensors, and flexible devices, but they have limitations including lower mechanical strength and environmental stability compared to insulating polymers. Insulating polymers excel in electrical insulation, chemical resistance, and mechanical durability, which are essential for use in wiring, protective coatings, and electronic packaging; however, their inability to conduct electricity restricts their use in applications requiring electrical functionality. Balancing the trade-offs between conductive and insulating polymers is crucial for tailored material selection in advanced electronic and industrial applications.

Future Trends in Polymer Electronics

Conductive polymers, such as polyaniline and PEDOT:PSS, enable flexible, lightweight electronic devices with tunable electrical properties, in contrast to insulating polymers used primarily for structural and dielectric applications. Future trends in polymer electronics emphasize enhancing conductivity through molecular doping, improving stability under environmental stress, and integrating hybrid nanomaterials to achieve superior performance. Emerging applications include wearable sensors, organic photovoltaics, and stretchable circuits, driving research toward scalable manufacturing and eco-friendly polymers.

Conductive Polymer vs Insulating Polymer Infographic

materialdif.com

materialdif.com