Elastomers exhibit high elasticity, allowing them to stretch and return to their original shape without permanent deformation, unlike plastics which tend to be rigid and retain their deformed shapes. The molecular structure of elastomers consists of loosely cross-linked polymers, providing flexibility and resilience, whereas plastics have tightly packed, linear or branched polymers that contribute to their hardness and brittleness. Elastomers are commonly used in applications requiring flexibility and impact resistance, while plastics are preferred for structural components due to their strength and durability.

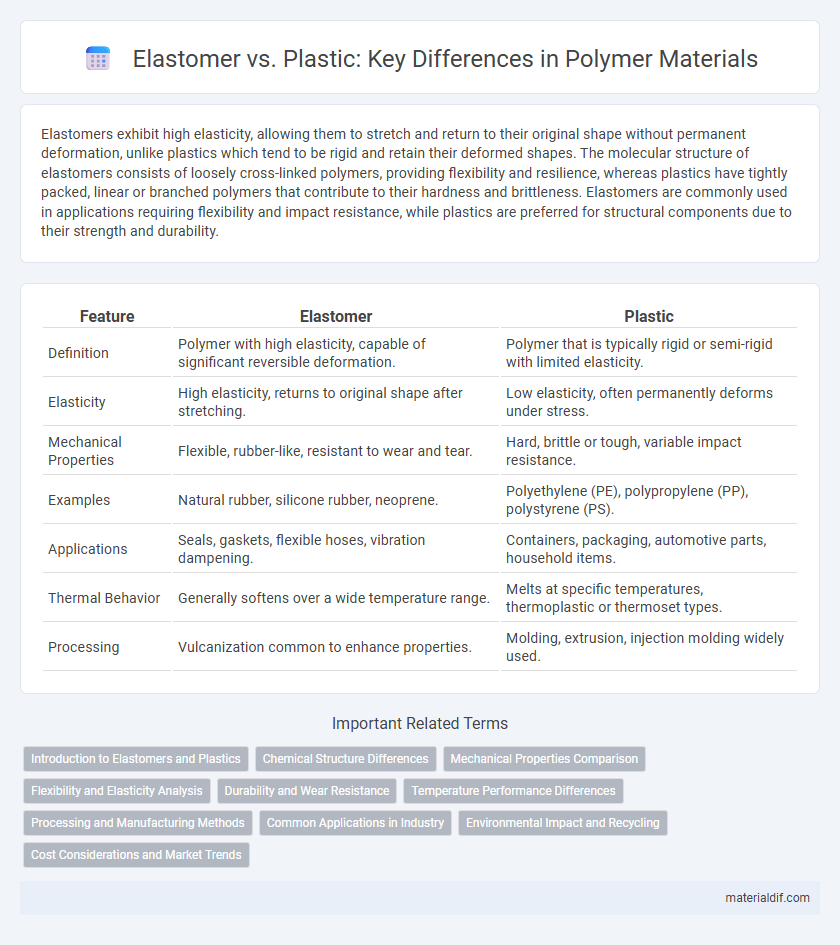

Table of Comparison

| Feature | Elastomer | Plastic |

|---|---|---|

| Definition | Polymer with high elasticity, capable of significant reversible deformation. | Polymer that is typically rigid or semi-rigid with limited elasticity. |

| Elasticity | High elasticity, returns to original shape after stretching. | Low elasticity, often permanently deforms under stress. |

| Mechanical Properties | Flexible, rubber-like, resistant to wear and tear. | Hard, brittle or tough, variable impact resistance. |

| Examples | Natural rubber, silicone rubber, neoprene. | Polyethylene (PE), polypropylene (PP), polystyrene (PS). |

| Applications | Seals, gaskets, flexible hoses, vibration dampening. | Containers, packaging, automotive parts, household items. |

| Thermal Behavior | Generally softens over a wide temperature range. | Melts at specific temperatures, thermoplastic or thermoset types. |

| Processing | Vulcanization common to enhance properties. | Molding, extrusion, injection molding widely used. |

Introduction to Elastomers and Plastics

Elastomers are polymers with viscoelasticity, exhibiting significant elasticity allowing them to stretch and return to their original shape. Plastics are polymers that primarily deform plastically and retain a permanent shape after molding or extrusion processes. Understanding the molecular structure and mechanical properties differentiates elastomers, such as natural rubber and synthetic rubber, from plastics like polyethylene and polypropylene.

Chemical Structure Differences

Elastomers consist of long, loosely crosslinked polymer chains that provide high elasticity and the ability to return to their original shape after deformation. Plastics typically have densely packed, more rigid polymer chains that result in a harder, less flexible material structure. The chemical crosslink density and chain mobility distinguish elastomers' rubber-like flexibility from the thermoplastic's rigid and durable properties.

Mechanical Properties Comparison

Elastomers exhibit high elasticity and flexibility, allowing them to undergo significant deformation and return to their original shape, whereas plastics generally have higher rigidity and lower elongation at break. The tensile strength of plastics typically surpasses that of elastomers, but elastomers outperform in impact resistance and resilience under cyclic loading. This mechanical behavior makes elastomers ideal for applications requiring flexibility and durability, while plastics are preferred for structural stability and load-bearing uses.

Flexibility and Elasticity Analysis

Elastomers exhibit superior flexibility and elasticity due to their long, cross-linked polymer chains, allowing them to stretch significantly and return to their original shape without permanent deformation. In contrast, plastics generally have more rigid, linear or branched polymer structures, resulting in limited flexibility and reduced elastic recovery. This fundamental difference in molecular structure defines elastomers' ability to withstand repetitive stress and strain, making them ideal for applications requiring high elasticity.

Durability and Wear Resistance

Elastomers exhibit superior elasticity and impact resistance, making them highly durable under repetitive stress and deformation, whereas plastics generally offer higher rigidity but can be prone to cracking under repeated flexing. Wear resistance in elastomers is enhanced by their ability to absorb and dissipate energy, which prevents surface degradation over time, while plastics often require additives or reinforcements to achieve comparable wear performance. Selecting between elastomers and plastics depends on the application demands for flexibility and abrasion resistance, with elastomers favored in dynamic environments and plastics in static load conditions.

Temperature Performance Differences

Elastomers maintain flexibility and elasticity at low temperatures, often below -50degC, due to their amorphous polymer chains, enabling effective performance in cold environments. Plastics typically become brittle and lose impact resistance when exposed to subzero temperatures because of their semi-crystalline or glassy structure. At elevated temperatures above 100degC, elastomers generally outperform plastics by retaining elasticity, while many plastics deform or melt, limiting their thermal stability.

Processing and Manufacturing Methods

Elastomers are processed through methods like extrusion, injection molding, and compression molding, which allow for flexible shaping and curing, often requiring vulcanization to enhance elasticity. Plastics typically undergo processes such as injection molding, blow molding, and thermoforming, enabling mass production of rigid or semi-rigid parts with precise dimensions. The key manufacturing distinction lies in elastomers' need for curing to achieve their elastic properties, while plastics rely on cooling and solidification for structural stability.

Common Applications in Industry

Elastomers are widely used in automotive industries for tires, seals, and vibration dampening components due to their elasticity and flexibility. Plastics dominate packaging, consumer goods, and construction sectors, offering rigidity, moldability, and cost-effectiveness. Both materials are essential in electronics, with elastomers providing insulation and plastics forming durable casings.

Environmental Impact and Recycling

Elastomers and plastics differ significantly in environmental impact and recycling potential; elastomers, such as natural rubber, often have higher biodegradability compared to most conventional plastics like polyethylene and polypropylene, which persist longer in landfills. Recycling elastomers poses challenges due to their cross-linked polymer structures, limiting mechanical recycling options, whereas many plastics can be more readily melted and reprocessed. Advances in devulcanization and chemical recycling techniques are crucial for improving elastomer sustainability and reducing long-term environmental pollution relative to plastic waste.

Cost Considerations and Market Trends

Elastomers generally incur higher production costs than plastics due to their complex polymer structures and specialized processing requirements. Market trends indicate growing demand for elastomers in automotive and medical applications, driven by their superior elasticity and durability compared to conventional plastics. Cost considerations also include lifecycle expenses, where elastomers offer better long-term value despite initial higher prices because of enhanced performance and resistance to wear.

Elastomer vs Plastic Infographic

materialdif.com

materialdif.com