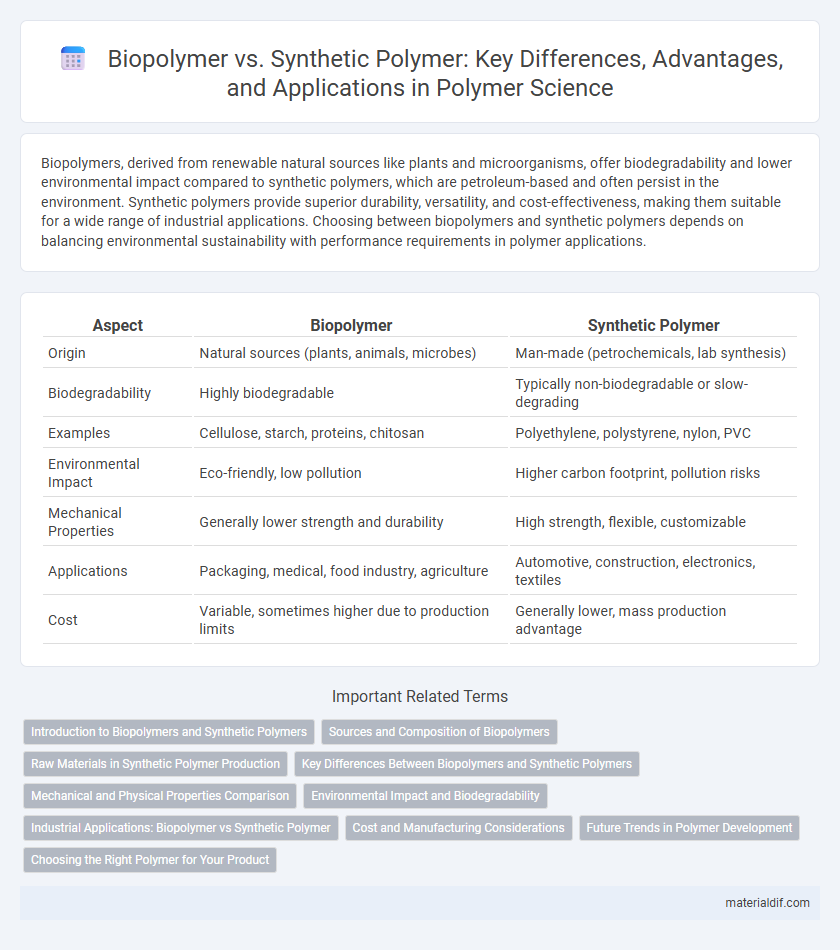

Biopolymers, derived from renewable natural sources like plants and microorganisms, offer biodegradability and lower environmental impact compared to synthetic polymers, which are petroleum-based and often persist in the environment. Synthetic polymers provide superior durability, versatility, and cost-effectiveness, making them suitable for a wide range of industrial applications. Choosing between biopolymers and synthetic polymers depends on balancing environmental sustainability with performance requirements in polymer applications.

Table of Comparison

| Aspect | Biopolymer | Synthetic Polymer |

|---|---|---|

| Origin | Natural sources (plants, animals, microbes) | Man-made (petrochemicals, lab synthesis) |

| Biodegradability | Highly biodegradable | Typically non-biodegradable or slow-degrading |

| Examples | Cellulose, starch, proteins, chitosan | Polyethylene, polystyrene, nylon, PVC |

| Environmental Impact | Eco-friendly, low pollution | Higher carbon footprint, pollution risks |

| Mechanical Properties | Generally lower strength and durability | High strength, flexible, customizable |

| Applications | Packaging, medical, food industry, agriculture | Automotive, construction, electronics, textiles |

| Cost | Variable, sometimes higher due to production limits | Generally lower, mass production advantage |

Introduction to Biopolymers and Synthetic Polymers

Biopolymers, derived from natural sources such as plants and animals, consist of materials like proteins, polysaccharides, and nucleic acids, offering biodegradability and renewable resource benefits. Synthetic polymers, including polyethylene, polystyrene, and nylon, are produced through chemical processes and exhibit tailored properties for diverse industrial applications. Understanding the structural differences and environmental impacts of biopolymers versus synthetic polymers is crucial for advancing sustainable material science.

Sources and Composition of Biopolymers

Biopolymers are derived from renewable biological sources such as plants, animals, and microorganisms, consisting primarily of natural macromolecules like polysaccharides, proteins, and nucleic acids. In contrast, synthetic polymers originate from petrochemical raw materials through chemical polymerization processes, leading to structures like polyethylene and polystyrene. The composition of biopolymers includes naturally occurring monomers such as glucose and amino acids, which contribute to their biodegradability and environmental sustainability.

Raw Materials in Synthetic Polymer Production

Synthetic polymer production relies primarily on petrochemicals derived from non-renewable fossil fuels such as crude oil, natural gas, and coal. These raw materials undergo polymerization processes to create versatile polymers like polyethylene, polystyrene, and polyvinyl chloride. Unlike biopolymers sourced from renewable biomass, synthetic polymers depend on extensive chemical refining and energy-intensive extraction methods.

Key Differences Between Biopolymers and Synthetic Polymers

Biopolymers, derived from renewable biological sources such as plants and microorganisms, exhibit biodegradability and environmental compatibility, contrasting synthetic polymers which are typically petroleum-based and non-biodegradable. The molecular structures of biopolymers, including polysaccharides and proteins, differ significantly from synthetic polymers like polyethylene and polystyrene, influencing their physical properties and applications. Industrial use of biopolymers targets sustainable packaging and medical devices, while synthetic polymers dominate in construction, automotive, and electronics due to superior durability and versatility.

Mechanical and Physical Properties Comparison

Biopolymers, derived from renewable resources, generally exhibit lower mechanical strength and thermal stability compared to synthetic polymers, which are engineered for superior durability and resistance. Synthetic polymers like polyethylene and polystyrene demonstrate high tensile strength, flexibility, and environmental resistance, whereas biopolymers such as PLA and PHB often have limited impact strength and are more prone to hydrolytic degradation. Advances in biopolymer composites are enhancing physical properties, but synthetic polymers remain dominant in applications demanding exceptional mechanical performance.

Environmental Impact and Biodegradability

Biopolymers, derived from renewable biological sources such as starch, cellulose, and proteins, offer enhanced biodegradability compared to synthetic polymers like polyethylene and polystyrene, which are petroleum-based and persist in the environment for decades. The environmental impact of biopolymers is significantly lower due to their ability to decompose naturally into non-toxic components, reducing landfill accumulation and microplastic pollution. Synthetic polymers, while durable and versatile, contribute heavily to plastic waste and toxic chemical release, posing long-term ecological risks.

Industrial Applications: Biopolymer vs Synthetic Polymer

Biopolymers, derived from renewable resources like starch, cellulose, and proteins, are increasingly utilized in packaging, agriculture, and biomedical industries due to their biodegradability and reduced environmental impact. Synthetic polymers such as polyethylene, polypropylene, and polystyrene dominate sectors requiring high durability, chemical resistance, and cost efficiency, including automotive, electronics, and construction applications. Industrial trends reveal a growing shift towards biopolymers for sustainable solutions, although synthetic polymers continue to lead in performance-critical and large-scale manufacturing processes.

Cost and Manufacturing Considerations

Biopolymers, derived from renewable biological sources, often incur higher production costs due to complex extraction and processing methods compared to synthetic polymers, which are mass-produced from petroleum-based materials with cost-efficient manufacturing techniques. The scalability of synthetic polymers benefits from established industrial infrastructure and lower raw material expenses, while biopolymer production faces challenges in achieving consistent quality and economic viability at large scales. Cost-effectiveness and manufacturing efficiency remain significant factors influencing the adoption of polymer types across various applications.

Future Trends in Polymer Development

Future trends in polymer development emphasize the increasing shift towards biodegradable biopolymers derived from renewable resources to address environmental concerns and reduce plastic pollution. Advances in sustainable synthesis techniques and bio-based monomers enable the creation of high-performance biopolymers with properties comparable to synthetic polymers. Innovations in polymer recycling and the design of hybrid polymers integrating both biopolymeric and synthetic components further enhance material functionality and lifecycle sustainability.

Choosing the Right Polymer for Your Product

Selecting the right polymer for your product depends heavily on the application requirements and environmental considerations. Biopolymers, derived from renewable sources like starch or cellulose, offer biodegradability and reduced ecological impact but may have limitations in mechanical strength and thermal stability. Synthetic polymers, such as polyethylene and polystyrene, provide superior durability, versatility, and cost-effectiveness but present challenges in sustainability and end-of-life disposal.

Biopolymer vs Synthetic Polymer Infographic

materialdif.com

materialdif.com